Ultrasonic sensors measure distance by emitting sound waves and detecting their echoes, making them ideal for environments with dust or smoke but less precise at long ranges. Laser sensors use focused light beams to provide highly accurate distance measurements and are better suited for detailed scanning tasks; explore the rest of the article to determine which sensor best fits Your specific needs.

Table of Comparison

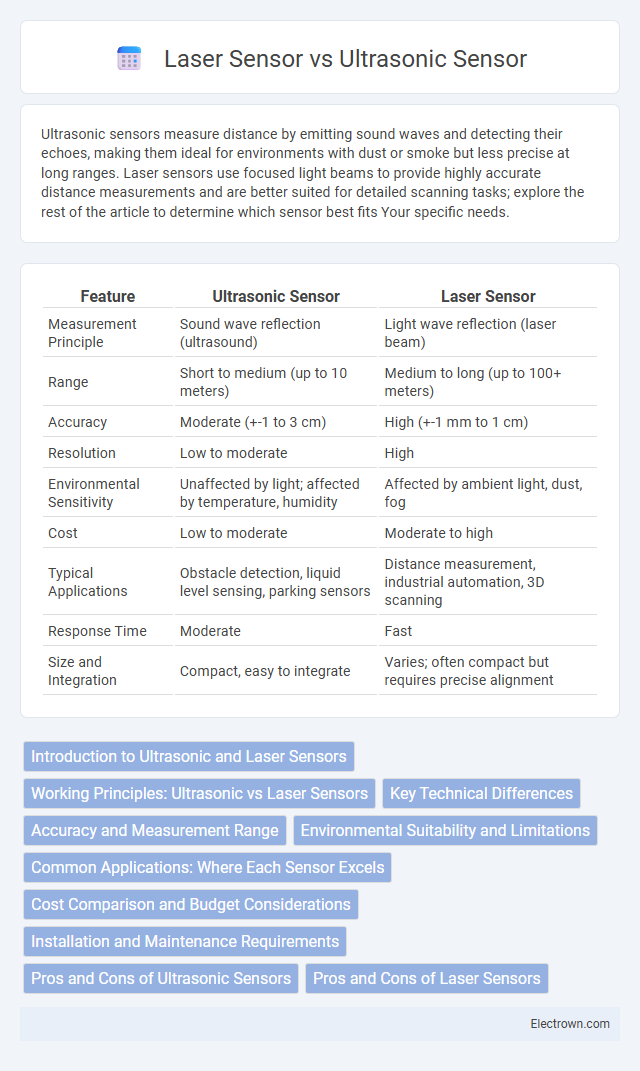

| Feature | Ultrasonic Sensor | Laser Sensor |

|---|---|---|

| Measurement Principle | Sound wave reflection (ultrasound) | Light wave reflection (laser beam) |

| Range | Short to medium (up to 10 meters) | Medium to long (up to 100+ meters) |

| Accuracy | Moderate (+-1 to 3 cm) | High (+-1 mm to 1 cm) |

| Resolution | Low to moderate | High |

| Environmental Sensitivity | Unaffected by light; affected by temperature, humidity | Affected by ambient light, dust, fog |

| Cost | Low to moderate | Moderate to high |

| Typical Applications | Obstacle detection, liquid level sensing, parking sensors | Distance measurement, industrial automation, 3D scanning |

| Response Time | Moderate | Fast |

| Size and Integration | Compact, easy to integrate | Varies; often compact but requires precise alignment |

Introduction to Ultrasonic and Laser Sensors

Ultrasonic sensors use high-frequency sound waves to detect the distance to an object by measuring the time it takes for the echo to return, making them ideal for applications in robotics and automotive parking systems. Laser sensors emit focused laser beams to measure distance with high precision by calculating the time of flight or phase shift of the reflected light, commonly used in industrial automation and 3D scanning. Both sensors provide non-contact measurement solutions but differ significantly in range, accuracy, and environmental sensitivity.

Working Principles: Ultrasonic vs Laser Sensors

Ultrasonic sensors operate by emitting high-frequency sound waves and measuring the time it takes for the echo to return, enabling distance detection through sound propagation. Laser sensors utilize focused light beams, measuring the time of flight or phase shift of reflected laser pulses to determine precise distances with high accuracy. Your choice depends on application needs, as ultrasonic sensors excel in detecting soft, irregular objects, while laser sensors offer superior resolution for small or reflective targets.

Key Technical Differences

Ultrasonic sensors use high-frequency sound waves to detect object distance and measure proximity, typically offering ranges up to several meters with moderate accuracy and susceptibility to environmental noise. Laser sensors emit focused light beams for distance measurement through time-of-flight or phase shift methods, providing higher precision, faster response times, and longer detection ranges compared to ultrasonic sensors. While ultrasonic sensors are cost-effective and perform well in detecting various surface types, laser sensors excel in applications requiring fine resolution and detailed spatial mapping.

Accuracy and Measurement Range

Ultrasonic sensors offer reliable accuracy within short to medium measurement ranges, typically up to 10 meters, but their precision can be affected by environmental factors like temperature and surface texture. Laser sensors provide superior accuracy, often measuring distances with millimeter precision, and boast much longer ranges, extending up to several hundred meters in ideal conditions. Your choice between these sensors should consider the need for high precision and extended range versus cost and environmental robustness.

Environmental Suitability and Limitations

Ultrasonic sensors excel in dusty, smoky, or foggy environments due to their sound wave technology, which is less affected by optical obstructions but can struggle with soft or angled surfaces that absorb or deflect sound waves. Laser sensors provide high-precision measurements in clean, clear conditions but their performance degrades significantly in environments with dust, smoke, rain, or fog, which scatter or absorb laser beams. Both sensors have limitations: ultrasonic sensors are limited by range and angular resolution, while laser sensors face challenges related to environmental contamination and reflective surfaces.

Common Applications: Where Each Sensor Excels

Ultrasonic sensors excel in applications requiring distance measurement in environments with dust, dirt, or varying surface textures, such as parking assistance, liquid level detection, and industrial automation. Laser sensors are ideal for high-precision tasks like barcode scanning, object profiling, and robotics, where accuracy and long-range measurement are critical. Your choice depends on whether you prioritize robust, cost-effective sensing or precise, detailed measurement for your application.

Cost Comparison and Budget Considerations

Ultrasonic sensors generally offer a lower cost solution compared to laser sensors, making them more suitable for budget-sensitive projects requiring basic distance measurement capabilities. Laser sensors, while more expensive, provide higher precision and longer range, justifying the investment for applications demanding accurate and rapid measurements. Budget considerations should balance the initial sensor cost against performance requirements and potential long-term benefits such as reduced maintenance and improved efficiency.

Installation and Maintenance Requirements

Ultrasonic sensors require straightforward installation with minimal calibration and are generally durable in harsh environments, making maintenance simple and infrequent. Laser sensors demand precise alignment during installation to ensure accurate measurements and often need periodic cleaning to prevent lens contamination and maintain optimal performance. Your choice depends on balancing ease of setup with ongoing maintenance needs based on the sensor's operating environment.

Pros and Cons of Ultrasonic Sensors

Ultrasonic sensors offer cost-effective distance measurement with robust performance in various lighting conditions and the ability to detect transparent or dark objects, making them ideal for industrial automation and obstacle avoidance. However, they face limitations such as lower accuracy and resolution compared to laser sensors, susceptibility to environmental noise, and limited range and angle of detection. Their performance can degrade in turbulent air or with soft materials that absorb sound waves, restricting applications requiring high precision or long-distance sensing.

Pros and Cons of Laser Sensors

Laser sensors offer high precision and long-range measurement capabilities, making them ideal for applications requiring exact distance detection and object profiling. Their ability to work effectively in various lighting conditions and detect small or transparent objects is a significant advantage over ultrasonic sensors. However, laser sensors can be more expensive, sensitive to environmental dust or smoke, and may require careful alignment to maintain accuracy.

Ultrasonic Sensor vs Laser Sensor Infographic

electrown.com

electrown.com