Incremental encoders provide precise digital signals to measure position and speed, ideal for applications requiring accurate rotational feedback, while resolvers offer robust analog output suited for harsh environments due to their durability and immunity to electrical noise. Explore the rest of the article to understand which option best fits your specific needs and application conditions.

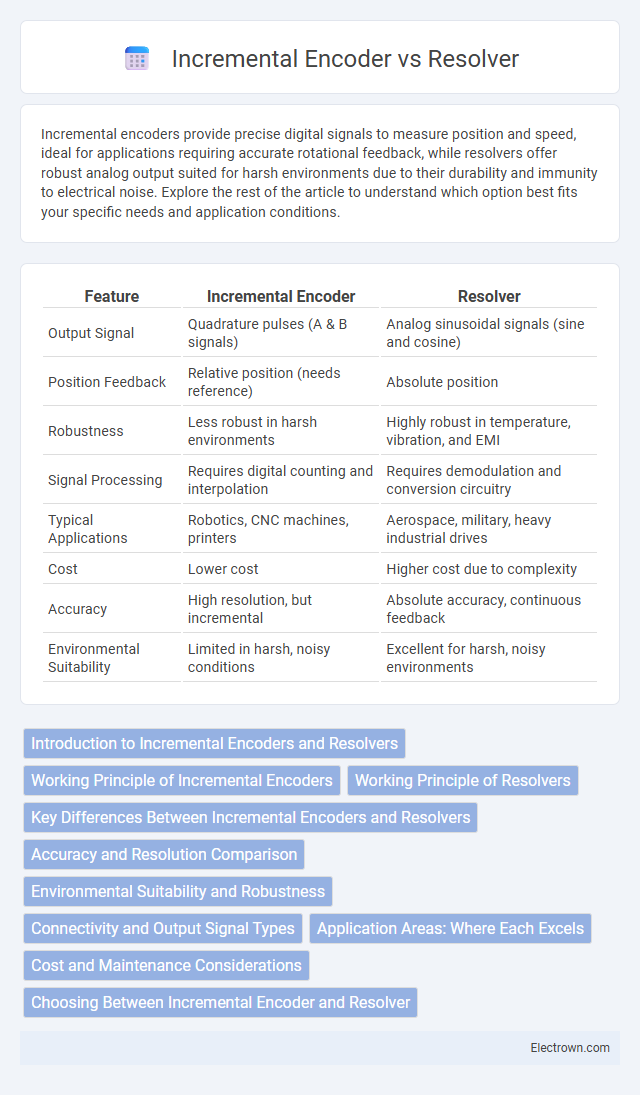

Table of Comparison

| Feature | Incremental Encoder | Resolver |

|---|---|---|

| Output Signal | Quadrature pulses (A & B signals) | Analog sinusoidal signals (sine and cosine) |

| Position Feedback | Relative position (needs reference) | Absolute position |

| Robustness | Less robust in harsh environments | Highly robust in temperature, vibration, and EMI |

| Signal Processing | Requires digital counting and interpolation | Requires demodulation and conversion circuitry |

| Typical Applications | Robotics, CNC machines, printers | Aerospace, military, heavy industrial drives |

| Cost | Lower cost | Higher cost due to complexity |

| Accuracy | High resolution, but incremental | Absolute accuracy, continuous feedback |

| Environmental Suitability | Limited in harsh, noisy conditions | Excellent for harsh, noisy environments |

Introduction to Incremental Encoders and Resolvers

Incremental encoders measure position by generating pulses corresponding to angular movement, offering high-resolution feedback critical for precision motion control in robotics and automation. Resolvers use electromagnetic induction to produce analog signals representing shaft position and speed, making them highly robust in harsh environments with extreme temperatures and vibrations. Your choice between an incremental encoder and a resolver depends on the required accuracy, environmental conditions, and signal processing capabilities for your application.

Working Principle of Incremental Encoders

Incremental encoders operate by generating a series of pulses as a rotary shaft moves, utilizing optical or magnetic sensors to detect position changes. These pulses correspond to incremental movements, allowing precise measurement of speed and direction without providing absolute position data. Unlike resolvers, which use analog signals to indicate rotor angle, incremental encoders rely on digital pulse outputs for real-time tracking in motion control systems.

Working Principle of Resolvers

Resolvers operate on the principle of electromagnetic induction, using a rotor and stator to convert mechanical position into electrical signals. The rotor's movement induces sinusoidal voltages in the stator windings, which vary proportionally with the shaft angle. Your precise control system benefits from a resolver's robustness and noise immunity in harsh environments compared to incremental encoders.

Key Differences Between Incremental Encoders and Resolvers

Incremental encoders provide digital pulse signals that represent position changes, enabling precise motion tracking with high resolution, whereas resolvers generate analog sine and cosine signals for robust, noise-resistant position feedback in harsh environments. Incremental encoders are typically used where cost-effective, high-accuracy feedback is required, while resolvers excel in applications needing high durability and immunity to electrical interference. Choosing the right device depends on your system's operational conditions, accuracy requirements, and signal processing capabilities.

Accuracy and Resolution Comparison

Incremental encoders provide high resolution by generating a fixed number of pulses per revolution, enabling precise position tracking with typical resolutions ranging from 100 to over 10,000 pulses per revolution. Resolvers offer robust angular position sensing with continuous analog output, delivering inherently high accuracy and resolution that often surpass incremental encoders in harsh environments due to their resistance to electrical noise and temperature extremes. While incremental encoders excel in digital precision for speed and position measurement, resolvers maintain superior accuracy under extreme operating conditions, making them ideal for demanding applications requiring reliable, high-resolution feedback.

Environmental Suitability and Robustness

Incremental encoders offer high precision in controlled environments but are sensitive to dust, moisture, and vibration, limiting their use in harsh industrial conditions. Resolvers excel in robust environments due to their inherent resistance to extreme temperatures, shock, and electromagnetic interference, making them ideal for heavy machinery and aerospace applications. Their rugged construction and analog signal output ensure reliable performance where durability and environmental resilience are critical.

Connectivity and Output Signal Types

Incremental encoders typically offer connectivity through standard interfaces such as TTL or HTL signals, providing quadrature output pulses for position and speed feedback. Resolvers, on the other hand, utilize analog sine and cosine output signals transmitted via robust differential wiring, making them more resilient in harsh environments. While incremental encoders generate discrete digital pulses, resolvers provide continuous analog outputs that require demodulation for accurate angular position information.

Application Areas: Where Each Excels

Incremental encoders excel in applications requiring precise speed and position feedback in automation, robotics, and CNC machinery due to their high resolution and cost-effectiveness. Resolvers are preferred in harsh environments like aerospace, military, and industrial motor control where robustness, temperature stability, and reliability under extreme conditions are critical. The choice depends on application-specific needs such as environmental resilience for resolvers and high-accuracy incremental feedback for encoders.

Cost and Maintenance Considerations

Incremental encoders generally offer lower upfront costs and simpler maintenance due to their straightforward design and widespread availability of replacement parts. Resolvers, while typically more expensive initially, provide superior durability and reliability in harsh environments, minimizing long-term maintenance expenses. Your choice between the two should balance immediate budget constraints against potential maintenance needs and operational conditions.

Choosing Between Incremental Encoder and Resolver

Choosing between an incremental encoder and a resolver depends on application requirements such as precision, environmental conditions, and signal reliability. Incremental encoders offer high-resolution digital signals ideal for precise position tracking in controlled environments, while resolvers provide robust analog feedback resistant to extreme temperatures, vibration, and electrical noise. Evaluating factors like accuracy, durability, and signal processing helps determine the optimal sensor for industrial automation or motion control systems.

Incremental Encoder vs Resolver Infographic

electrown.com

electrown.com