The 4-20mA signal offers greater noise resistance and longer transmission distances compared to the 0-10V signal, making it ideal for industrial environments requiring precise current loop measurements. Discover how your choice between these signals can impact system performance by reading the full article.

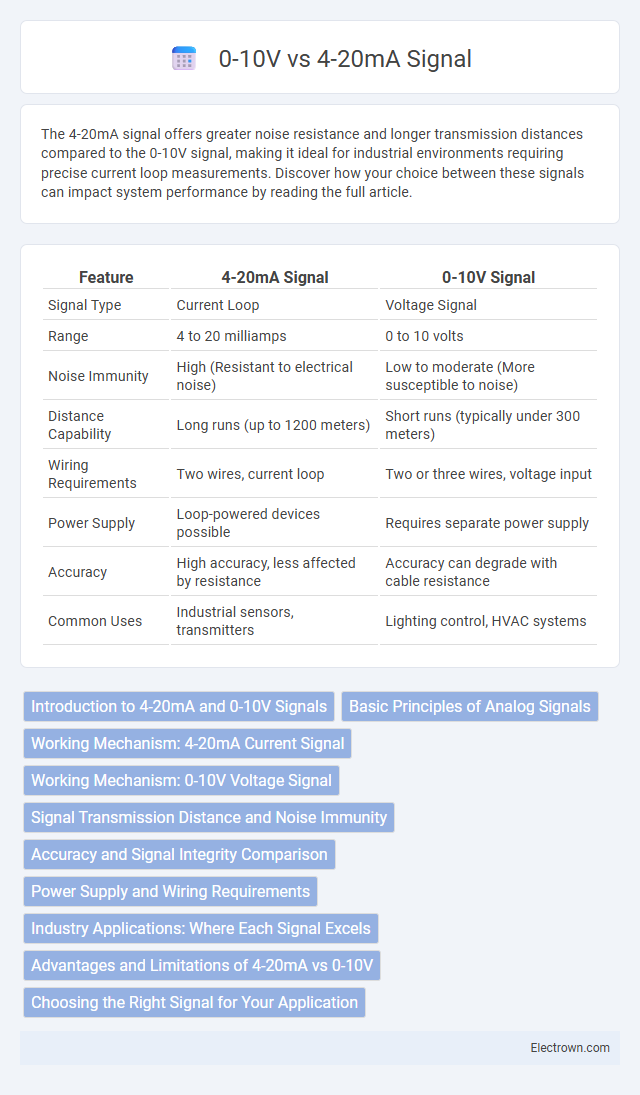

Table of Comparison

| Feature | 4-20mA Signal | 0-10V Signal |

|---|---|---|

| Signal Type | Current Loop | Voltage Signal |

| Range | 4 to 20 milliamps | 0 to 10 volts |

| Noise Immunity | High (Resistant to electrical noise) | Low to moderate (More susceptible to noise) |

| Distance Capability | Long runs (up to 1200 meters) | Short runs (typically under 300 meters) |

| Wiring Requirements | Two wires, current loop | Two or three wires, voltage input |

| Power Supply | Loop-powered devices possible | Requires separate power supply |

| Accuracy | High accuracy, less affected by resistance | Accuracy can degrade with cable resistance |

| Common Uses | Industrial sensors, transmitters | Lighting control, HVAC systems |

Introduction to 4-20mA and 0-10V Signals

4-20mA and 0-10V signals are common analog communication standards used in industrial automation and control systems to transmit sensor data. The 4-20mA current loop is favored for its noise immunity and ability to detect wire breaks, making it ideal for long-distance signal transmission. The 0-10V voltage signal offers simplicity and compatibility with many devices but is more susceptible to signal degradation over extended cable runs.

Basic Principles of Analog Signals

The 4-20mA signal operates as a current loop where 4mA represents the minimum measurement and 20mA the maximum, providing inherent noise immunity and easy detection of faults such as breaks. The 0-10V signal works by outputting voltage levels proportional to the measured parameter, with 0V indicating minimum and 10V maximum values, but it is more susceptible to voltage drop and electrical interference over long distances. Both analog signals convert physical measurements into continuous electrical values, but current signals like 4-20mA ensure greater accuracy in industrial environments due to consistent current flow regardless of wire resistance.

Working Mechanism: 4-20mA Current Signal

The 4-20mA current signal operates by transmitting a proportional current, ranging from 4mA (representing the lowest measurement value) to 20mA (indicating the highest), allowing precise and noise-resistant data transfer over long distances. This analog current loop ensures consistent signal integrity, as the current remains stable despite voltage fluctuations or resistance changes in the wiring. Industrial control systems utilize the 4-20mA signal extensively for sensors and actuators due to its reliability and ability to detect wiring faults such as open circuits when the current falls below 4mA.

Working Mechanism: 0-10V Voltage Signal

The 0-10V voltage signal operates by varying the output voltage between 0 and 10 volts to represent the full range of a measurable parameter, such as temperature, pressure, or speed. This signal type is commonly used in HVAC and industrial control systems where the voltage level directly corresponds to the process variable, enabling easy integration with controllers and sensors. Because it relies on voltage as the transmitting medium, the 0-10V signal is sensitive to electrical noise and signal degradation over long distances compared to current loop systems like 4-20mA.

Signal Transmission Distance and Noise Immunity

4-20mA current signals maintain signal integrity over long distances up to 1,200 meters without significant voltage drop, offering superior noise immunity compared to 0-10V voltage signals that typically degrade beyond 100-300 meters due to voltage loss. The constant current in 4-20mA loops allows better rejection of electromagnetic interference, making them ideal for industrial environments. In contrast, 0-10V signals are more susceptible to noise and voltage fluctuation, limiting their effective transmission range in noisy conditions.

Accuracy and Signal Integrity Comparison

The 4-20mA current loop offers superior accuracy and signal integrity over long distances due to its immunity to voltage drops and electrical noise, maintaining consistent signal strength even in harsh industrial environments. In contrast, the 0-10V voltage signal is more susceptible to signal degradation and interference, especially over extended cable runs, which can lead to inaccurate readings and reduced reliability. Therefore, for applications requiring precise and stable measurements, the 4-20mA standard is generally preferred for its robustness and noise resistance.

Power Supply and Wiring Requirements

The 4-20mA signal requires a two-wire system often powered by a current loop, which can supply both signal and power through the same pair of wires, reducing wiring complexity and allowing longer transmission distances. In contrast, the 0-10V signal needs a separate power supply and a three-wire connection to transmit voltage independently from the power source, making it more susceptible to voltage drops over long cable runs. For effective wiring, 4-20mA loops benefit from twisted pair cables with proper shielding to minimize interference, whereas 0-10V systems demand careful voltage drop management and stable power supply to maintain signal integrity.

Industry Applications: Where Each Signal Excels

The 4-20mA signal excels in industrial environments requiring robust, long-distance transmission with high resistance to electrical noise, commonly used in process control systems like oil refineries and chemical plants. The 0-10V signal is preferred for shorter-distance applications with simpler wiring needs, often found in building automation, HVAC controls, and lighting systems. Both signals serve critical roles but are selected based on environment, noise immunity, and distance requirements in industry applications.

Advantages and Limitations of 4-20mA vs 0-10V

The 4-20mA current signal offers higher noise immunity and longer transmission distances compared to the 0-10V voltage signal, making it ideal for industrial environments with electrical interference. The 0-10V signal provides simplicity and cost-effectiveness for short-distance communication but is more susceptible to voltage drop and interference. While 4-20mA supports intrinsic fault detection through current loop monitoring, 0-10V systems often require additional circuitry for signal integrity assurance.

Choosing the Right Signal for Your Application

Selecting between 4-20mA and 0-10V signals depends on factors such as distance, noise immunity, and power consumption. The 4-20mA current loop is preferred for long-distance transmission and noisy industrial environments due to its higher resistance to signal degradation. Conversely, 0-10V voltage signals are suitable for short-distance applications with low electrical interference and simpler wiring requirements.

4-20mA vs 0-10V Signal Infographic

electrown.com

electrown.com