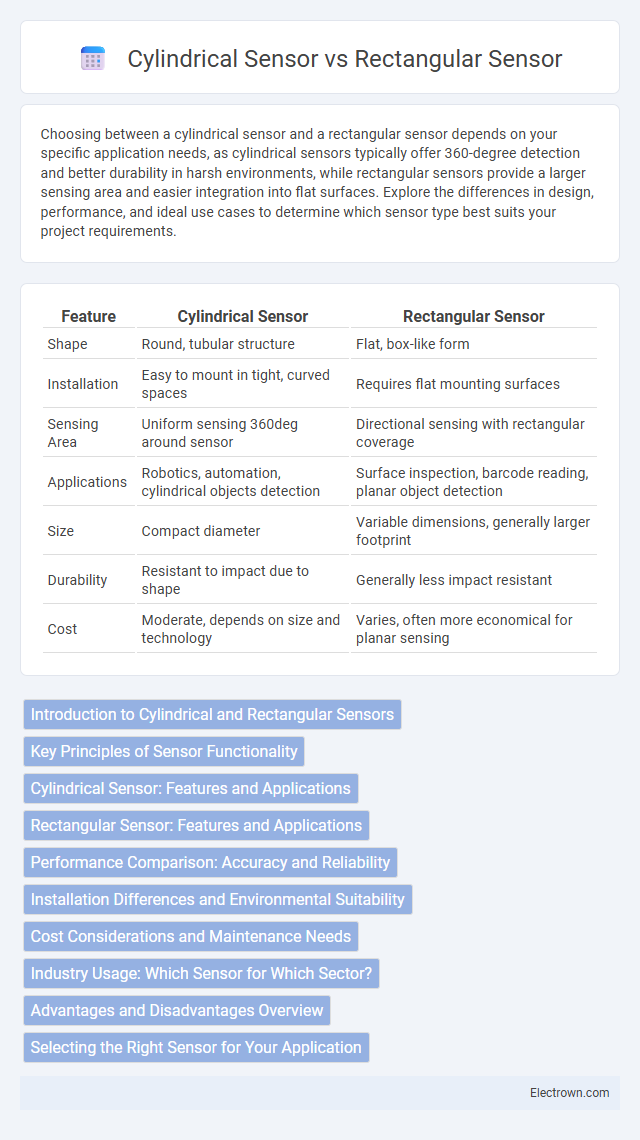

Choosing between a cylindrical sensor and a rectangular sensor depends on your specific application needs, as cylindrical sensors typically offer 360-degree detection and better durability in harsh environments, while rectangular sensors provide a larger sensing area and easier integration into flat surfaces. Explore the differences in design, performance, and ideal use cases to determine which sensor type best suits your project requirements.

Table of Comparison

| Feature | Cylindrical Sensor | Rectangular Sensor |

|---|---|---|

| Shape | Round, tubular structure | Flat, box-like form |

| Installation | Easy to mount in tight, curved spaces | Requires flat mounting surfaces |

| Sensing Area | Uniform sensing 360deg around sensor | Directional sensing with rectangular coverage |

| Applications | Robotics, automation, cylindrical objects detection | Surface inspection, barcode reading, planar object detection |

| Size | Compact diameter | Variable dimensions, generally larger footprint |

| Durability | Resistant to impact due to shape | Generally less impact resistant |

| Cost | Moderate, depends on size and technology | Varies, often more economical for planar sensing |

Introduction to Cylindrical and Rectangular Sensors

Cylindrical sensors offer a rotationally symmetric design ideal for detecting objects in round or confined spaces, enhancing accuracy in industrial automation and robotics. Rectangular sensors provide a defined detection area with linear edges, suitable for applications requiring precise alignment and coverage over flat surfaces. Your choice between these sensor types depends on the spatial constraints and the specific detection geometry of your application.

Key Principles of Sensor Functionality

Cylindrical sensors utilize a radial detection pattern that enables 360-degree sensing, making them ideal for applications requiring uniform sensitivity around the sensor axis. Rectangular sensors operate based on a linear detection field with a defined width and height, offering precise targeting in specific directional zones. Both sensor types rely on principles of electromagnetic or optical signal modulation and reflection to detect presence or measure distance accurately.

Cylindrical Sensor: Features and Applications

Cylindrical sensors feature a compact, tubular shape that allows for easy integration into tight or constrained spaces, making them ideal for automation and robotics applications where precise detection is required. Their seamless design provides durability and resistance to environmental factors such as dust and moisture, enhancing reliability in industrial settings. You can leverage cylindrical sensors for object detection, positioning, and speed monitoring in manufacturing lines and conveyor systems due to their high sensitivity and consistent performance.

Rectangular Sensor: Features and Applications

Rectangular sensors offer a larger active area and higher pixel count, providing enhanced image resolution and detail compared to cylindrical sensors. Their distinct shape allows for easier integration in devices such as smartphones, tablets, and cameras, enabling improved field of view and image processing efficiency. You can rely on rectangular sensors for applications requiring precision, including machine vision, medical imaging, and professional photography.

Performance Comparison: Accuracy and Reliability

Cylindrical sensors generally offer higher accuracy in detecting rotational or angular displacement due to their uniform geometry, which reduces measurement errors caused by alignment issues. Rectangular sensors provide enhanced reliability in applications requiring precise linear positioning, benefiting from a stable surface area that minimizes signal drift under varying environmental conditions. Both sensor types deliver optimal performance when selected based on specific use-case requirements, with cylindrical sensors excelling in rotational accuracy and rectangular sensors in consistent linear reliability.

Installation Differences and Environmental Suitability

Cylindrical sensors feature a compact, round design ideal for straightforward installation in tight spaces, making them suitable for dynamic environments with limited mounting areas. Rectangular sensors offer a flat, larger surface area that enables easy alignment and stable placement on flat surfaces, enhancing performance in controlled environments with precise positioning requirements. Understanding your installation space and environmental conditions will help you choose the best sensor shape for optimal functionality and durability.

Cost Considerations and Maintenance Needs

Cylindrical sensors typically incur higher manufacturing costs due to their complex design and precision engineering, while rectangular sensors benefit from simpler, cost-effective production processes. Maintenance needs for cylindrical sensors often involve more frequent calibration and specialized servicing to preserve accuracy, whereas rectangular sensors generally require less frequent upkeep and are easier to maintain. Cost considerations favor rectangular sensors in budget-sensitive applications, whereas cylindrical sensors are preferred in environments demanding high precision despite higher maintenance expenses.

Industry Usage: Which Sensor for Which Sector?

Cylindrical sensors are widely used in manufacturing and automation industries due to their compact design and ease of integration into robotic arms and conveyor systems, providing reliable object detection in tight spaces. Rectangular sensors, favored in packaging and material handling sectors, offer a larger detection surface ideal for monitoring wide product flows and ensuring precise alignment. Your choice depends on the physical environment and detection range requirements typical in sectors like automotive, food processing, or electronics assembly.

Advantages and Disadvantages Overview

Cylindrical sensors offer uniform sensitivity around their circumference, making them ideal for detecting objects in environments where direction varies, but their curved design often limits mounting options and spatial integration compared to rectangular sensors. Rectangular sensors provide straightforward installation and better alignment for linear or planar measurements, benefiting applications requiring precise edge detection or structured layouts, though they may lack omnidirectional sensitivity and can be more susceptible to misalignment. Choosing between cylindrical and rectangular sensor types depends on specific application needs regarding shape compatibility, sensing range, and environmental conditions.

Selecting the Right Sensor for Your Application

Choosing the right sensor for your application depends on factors such as space constraints, detection range, and target shape. Cylindrical sensors offer versatile mounting and are ideal for confined spaces with their round design, while rectangular sensors provide a larger sensing surface and better alignment for flat or irregular objects. Evaluating your specific sensing environment and object profile ensures your choice maximizes accuracy and efficiency.

Cylindrical Sensor vs Rectangular Sensor Infographic

electrown.com

electrown.com