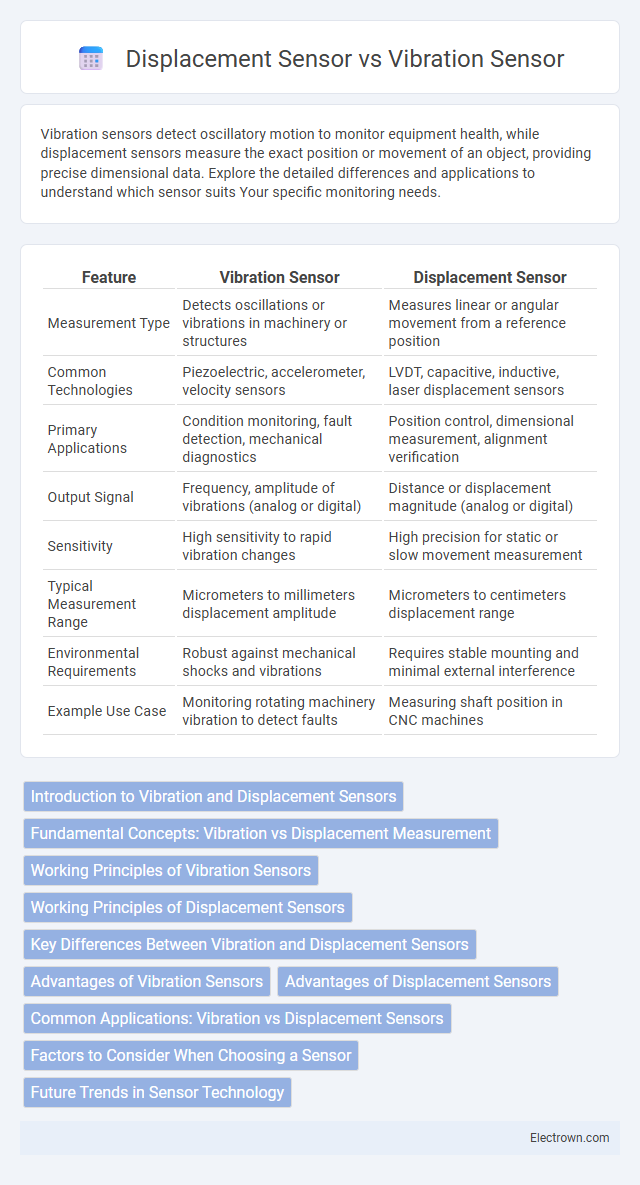

Vibration sensors detect oscillatory motion to monitor equipment health, while displacement sensors measure the exact position or movement of an object, providing precise dimensional data. Explore the detailed differences and applications to understand which sensor suits Your specific monitoring needs.

Table of Comparison

| Feature | Vibration Sensor | Displacement Sensor |

|---|---|---|

| Measurement Type | Detects oscillations or vibrations in machinery or structures | Measures linear or angular movement from a reference position |

| Common Technologies | Piezoelectric, accelerometer, velocity sensors | LVDT, capacitive, inductive, laser displacement sensors |

| Primary Applications | Condition monitoring, fault detection, mechanical diagnostics | Position control, dimensional measurement, alignment verification |

| Output Signal | Frequency, amplitude of vibrations (analog or digital) | Distance or displacement magnitude (analog or digital) |

| Sensitivity | High sensitivity to rapid vibration changes | High precision for static or slow movement measurement |

| Typical Measurement Range | Micrometers to millimeters displacement amplitude | Micrometers to centimeters displacement range |

| Environmental Requirements | Robust against mechanical shocks and vibrations | Requires stable mounting and minimal external interference |

| Example Use Case | Monitoring rotating machinery vibration to detect faults | Measuring shaft position in CNC machines |

Introduction to Vibration and Displacement Sensors

Vibration sensors detect oscillations or mechanical vibrations in machinery, enabling early fault detection and maintenance to prevent equipment failure. Displacement sensors measure the physical distance or position change of an object, crucial for precision monitoring in manufacturing and automation systems. Understanding the specific application helps you select the right sensor to optimize performance and reliability in your equipment.

Fundamental Concepts: Vibration vs Displacement Measurement

Vibration sensors measure oscillatory motion by detecting acceleration, velocity, or frequency changes, providing insights into mechanical health and dynamic behavior of machinery. Displacement sensors quantify the linear or angular distance moved from a reference position, offering precise position or gap measurements. Both sensors complement each other in condition monitoring by capturing different aspects of motion--vibration sensors focus on time-based dynamic variations, whereas displacement sensors track static or slow positional changes.

Working Principles of Vibration Sensors

Vibration sensors operate by detecting oscillatory motion through various technologies such as piezoelectric, capacitive, or MEMS mechanisms, converting mechanical vibrations into electrical signals for monitoring equipment health or structural integrity. These sensors measure parameters like frequency, amplitude, and acceleration to identify faults, imbalances, or wear in rotating machinery. Unlike displacement sensors that track positional changes, vibration sensors focus on dynamic movement, providing critical data for predictive maintenance and real-time condition monitoring.

Working Principles of Displacement Sensors

Displacement sensors operate based on the principle of measuring the distance between the sensor and the target object, typically utilizing methods such as capacitive, inductive, or ultrasonic detection. Capacitive displacement sensors detect changes in capacitance caused by the variation in the distance to the target, while inductive sensors measure displacement by detecting changes in electromagnetic fields. Ultrasonic displacement sensors emit high-frequency sound waves and calculate distance by measuring the time it takes for the echo to return from the target surface.

Key Differences Between Vibration and Displacement Sensors

Vibration sensors measure oscillatory motion or acceleration to detect mechanical vibrations in machines, while displacement sensors capture the linear or angular movement of an object relative to a reference point. Vibration sensors typically use piezoelectric or accelerometer technology for dynamic monitoring, whereas displacement sensors utilize capacitive, inductive, or laser-based methods for precise positional tracking. Understanding these key differences helps you choose the right sensor type for applications requiring either motion detection or dimensional measurement.

Advantages of Vibration Sensors

Vibration sensors provide real-time monitoring of mechanical equipment, enabling early detection of imbalances, misalignments, or bearing failures that displacement sensors may not capture as effectively. Their ability to measure rapid oscillations with high sensitivity helps prevent costly downtime and extends machinery lifespan. You benefit from enhanced predictive maintenance and improved safety by integrating vibration sensors in industrial systems.

Advantages of Displacement Sensors

Displacement sensors offer higher precision in measuring position changes compared to vibration sensors, making them ideal for applications requiring exact dimensional monitoring. They provide continuous real-time data on the actual movement or distance between objects, enhancing accuracy in quality control and mechanical systems diagnostics. These sensors are less affected by external vibrations, ensuring reliable readings in environments with high mechanical noise.

Common Applications: Vibration vs Displacement Sensors

Vibration sensors are widely used in industrial equipment monitoring, predictive maintenance, and machinery health diagnostics to detect abnormal vibrations indicating potential failures. Displacement sensors are essential in precision engineering, robotics, and structural health monitoring where accurate measurement of position, distance, or movement is crucial. Your choice between vibration and displacement sensors depends on whether you need to monitor oscillation frequency or precise positional changes in your application.

Factors to Consider When Choosing a Sensor

Selecting between a vibration sensor and a displacement sensor depends on factors such as measurement range, sensitivity, and environmental conditions. Vibration sensors excel in detecting dynamic movements and frequency analysis, while displacement sensors provide precise measurement of position or distance changes. Your specific application requirements, including response time and durability, will determine the most suitable sensor type.

Future Trends in Sensor Technology

Vibration sensors and displacement sensors are increasingly integrated with advanced IoT connectivity and AI-driven analytics, enabling predictive maintenance and real-time monitoring across industries. Future trends emphasize miniaturization, enhanced sensitivity, and wireless capabilities, allowing your systems to achieve greater accuracy and efficiency while reducing downtime. Advances in smart sensor networks will transform these devices into autonomous units capable of self-diagnosis and adaptive calibration for optimal performance.

Vibration Sensor vs Displacement Sensor Infographic

electrown.com

electrown.com