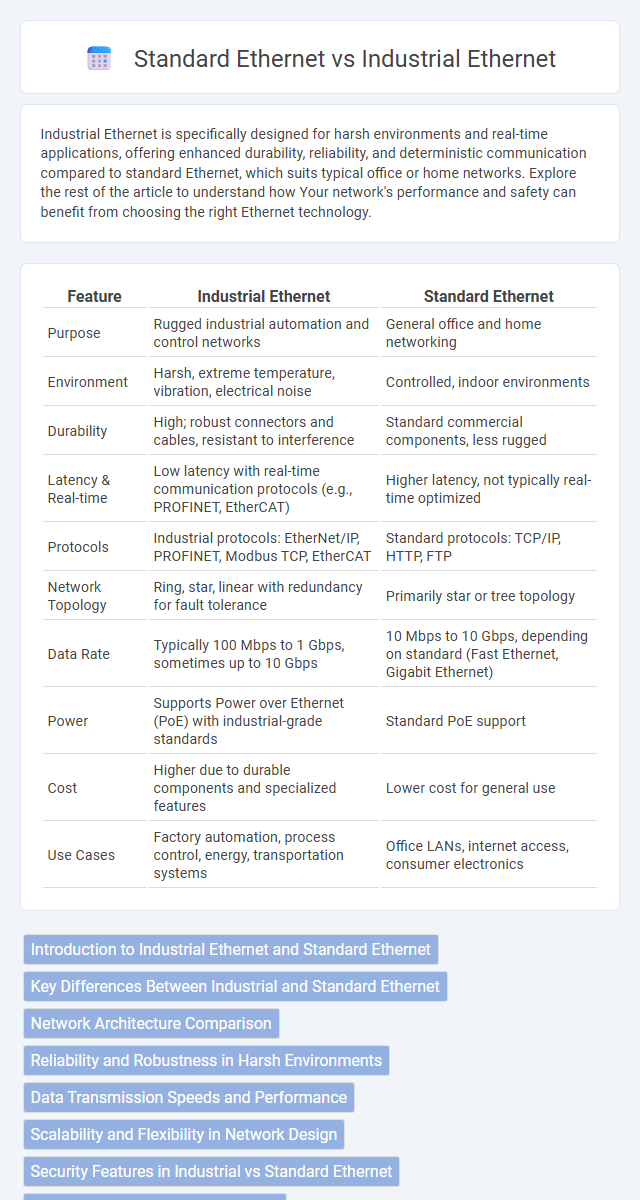

Industrial Ethernet is specifically designed for harsh environments and real-time applications, offering enhanced durability, reliability, and deterministic communication compared to standard Ethernet, which suits typical office or home networks. Explore the rest of the article to understand how Your network's performance and safety can benefit from choosing the right Ethernet technology.

Table of Comparison

| Feature | Industrial Ethernet | Standard Ethernet |

|---|---|---|

| Purpose | Rugged industrial automation and control networks | General office and home networking |

| Environment | Harsh, extreme temperature, vibration, electrical noise | Controlled, indoor environments |

| Durability | High; robust connectors and cables, resistant to interference | Standard commercial components, less rugged |

| Latency & Real-time | Low latency with real-time communication protocols (e.g., PROFINET, EtherCAT) | Higher latency, not typically real-time optimized |

| Protocols | Industrial protocols: EtherNet/IP, PROFINET, Modbus TCP, EtherCAT | Standard protocols: TCP/IP, HTTP, FTP |

| Network Topology | Ring, star, linear with redundancy for fault tolerance | Primarily star or tree topology |

| Data Rate | Typically 100 Mbps to 1 Gbps, sometimes up to 10 Gbps | 10 Mbps to 10 Gbps, depending on standard (Fast Ethernet, Gigabit Ethernet) |

| Power | Supports Power over Ethernet (PoE) with industrial-grade standards | Standard PoE support |

| Cost | Higher due to durable components and specialized features | Lower cost for general use |

| Use Cases | Factory automation, process control, energy, transportation systems | Office LANs, internet access, consumer electronics |

Introduction to Industrial Ethernet and Standard Ethernet

Industrial Ethernet is designed for robust, real-time communication in harsh manufacturing environments, offering enhanced durability, deterministic data transfer, and resistance to electromagnetic interference compared to Standard Ethernet. Standard Ethernet serves general networking needs with flexible, scalable, and cost-effective solutions primarily suited for office and home environments. Understanding these differences helps you select the appropriate network technology for reliable industrial automation or everyday data communication.

Key Differences Between Industrial and Standard Ethernet

Industrial Ethernet is designed for harsh environments, offering enhanced ruggedness, resistance to electromagnetic interference, and real-time data transmission capabilities, unlike Standard Ethernet which is optimized for office or home settings. It supports deterministic communication with protocols such as PROFINET and EtherNet/IP, ensuring low latency and high reliability critical for automation systems. Standard Ethernet emphasizes high throughput and easy scalability but lacks the robustness and specialized features required for industrial control and monitoring applications.

Network Architecture Comparison

Industrial Ethernet features ruggedized network architecture designed for real-time, deterministic communication in harsh environments, supporting protocols like PROFINET and EtherNet/IP. Standard Ethernet utilizes a general-purpose network architecture optimized for typical office or home environments, prioritizing flexibility and scalability over strict timing guarantees. The key architectural difference lies in Industrial Ethernet's enhanced redundancy, lower latency, and synchronized data transfer to meet demanding industrial automation requirements.

Reliability and Robustness in Harsh Environments

Industrial Ethernet is engineered for enhanced reliability and robustness, featuring rugged connectors, extended temperature ranges, and resistance to electromagnetic interference essential for harsh environments like factories and outdoor installations. Standard Ethernet lacks these specialized protections, making it less suitable for environments with extreme temperatures, vibrations, or electrical noise. Your network performance in demanding industrial settings depends on Industrial Ethernet's superior durability and consistent operation under adverse conditions.

Data Transmission Speeds and Performance

Industrial Ethernet offers enhanced data transmission speeds and performance tailored for harsh environments, providing real-time communication with low latency and high reliability. It supports deterministic data transfer and prioritizes traffic to maintain consistent network performance under industrial conditions, unlike Standard Ethernet, which is optimized for general office or home use with typical non-critical bandwidth needs. Your choice of Industrial Ethernet ensures superior network efficiency and robustness critical for automated systems and process controls.

Scalability and Flexibility in Network Design

Industrial Ethernet offers superior scalability and flexibility compared to Standard Ethernet by supporting ruggedized devices and real-time communication protocols essential for complex automation environments. Its enhanced network design capabilities allow seamless integration of diverse industrial equipment while maintaining high performance in harsh conditions. Your network can adapt more efficiently to expanding operations and dynamic industrial requirements with Industrial Ethernet's robust infrastructure.

Security Features in Industrial vs Standard Ethernet

Industrial Ethernet incorporates advanced security features such as robust encryption protocols, intrusion detection systems, and real-time network monitoring designed to withstand harsh industrial environments and cyber threats. Standard Ethernet often lacks these specialized protections, focusing more on basic network functionality rather than comprehensive security measures tailored to critical infrastructure. Your industrial network security is significantly enhanced by the resilience and protective mechanisms inherent in Industrial Ethernet, ensuring reliable operations and safeguarding sensitive data.

Protocol Support and Compatibility

Industrial Ethernet protocols such as PROFINET, EtherNet/IP, and Modbus TCP are designed to support real-time communication and deterministic data transfer, ensuring reliable performance in harsh industrial environments. Standard Ethernet primarily supports common protocols like TCP/IP and UDP, which are suited for general networking but lack the real-time capabilities and robustness needed for automation systems. Your choice between Industrial Ethernet and Standard Ethernet depends on the need for protocol compatibility with industrial devices and the requirement for timely, fault-tolerant communication.

Cost Considerations and Total Cost of Ownership

Industrial Ethernet typically incurs higher initial costs than Standard Ethernet due to ruggedized components designed for harsh environments. However, its enhanced durability and reduced downtime contribute to a lower Total Cost of Ownership (TCO) by minimizing maintenance and replacement expenses. Long-term savings from improved reliability and extended equipment lifespan often offset the upfront investment in Industrial Ethernet infrastructure.

Choosing the Right Ethernet Solution for Your Application

Industrial Ethernet offers enhanced durability, real-time communication, and resistance to harsh environments, making it ideal for manufacturing and automation processes. Standard Ethernet provides cost-effective, high-speed connectivity suited for office networks and general data transfer. Selecting the right Ethernet solution depends on specific application requirements such as environmental conditions, latency demands, and network reliability.

Industrial Ethernet vs Standard Ethernet Infographic

electrown.com

electrown.com