MCC (Multi-Class Classification) and PCC (Probabilistic Classifier Chains) differ fundamentally in handling multiple labels, with MCC assigning a single label per instance while PCC models label dependencies to improve prediction accuracy. Explore the detailed comparison to understand which method better suits Your multi-label classification needs.

Table of Comparison

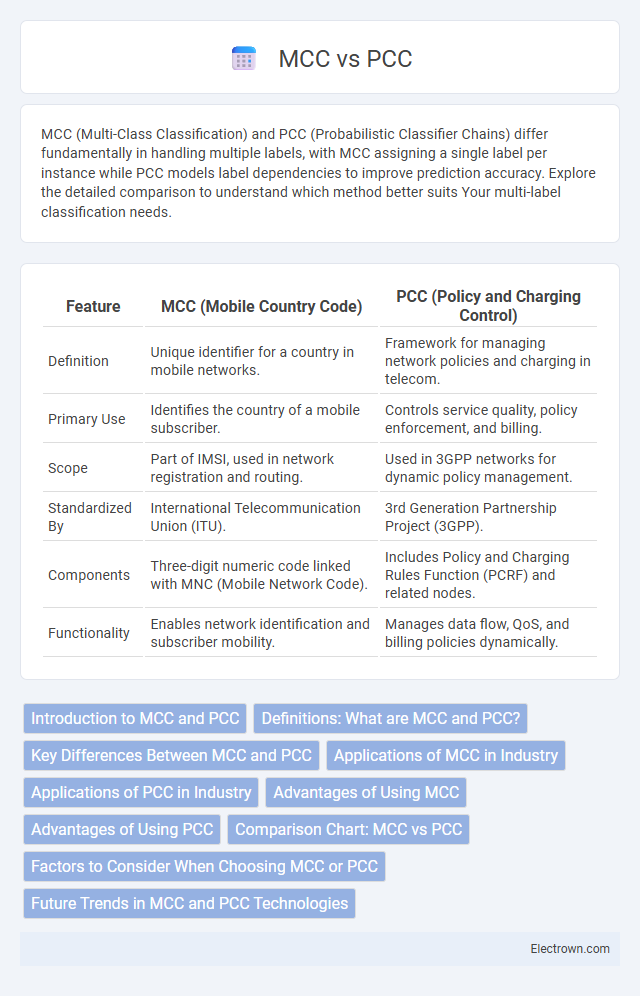

| Feature | MCC (Mobile Country Code) | PCC (Policy and Charging Control) |

|---|---|---|

| Definition | Unique identifier for a country in mobile networks. | Framework for managing network policies and charging in telecom. |

| Primary Use | Identifies the country of a mobile subscriber. | Controls service quality, policy enforcement, and billing. |

| Scope | Part of IMSI, used in network registration and routing. | Used in 3GPP networks for dynamic policy management. |

| Standardized By | International Telecommunication Union (ITU). | 3rd Generation Partnership Project (3GPP). |

| Components | Three-digit numeric code linked with MNC (Mobile Network Code). | Includes Policy and Charging Rules Function (PCRF) and related nodes. |

| Functionality | Enables network identification and subscriber mobility. | Manages data flow, QoS, and billing policies dynamically. |

Introduction to MCC and PCC

MCC (Multi-Commodity Container) and PCC (Pure Car Carrier) are two specialized types of cargo vessels designed to transport different types of goods efficiently across global shipping routes. MCC ships combine the capability to carry various containerized goods and commodities, optimizing space usage and logistics for mixed cargo demands. PCC vessels are specifically engineered for transporting cars and other vehicles, featuring tailored decks and securing systems to ensure safe transport of automotive shipments.

Definitions: What are MCC and PCC?

MCC (Multiple Correspondence Analysis) is a statistical technique used to analyze and visualize patterns in categorical data by transforming it into a geometric space. PCC (Pearson Correlation Coefficient) measures the linear correlation between two continuous variables, quantifying the strength and direction of their relationship with values ranging from -1 to 1. MCC is primarily applied in categorical data analysis, while PCC is utilized for understanding associations in numerical data sets.

Key Differences Between MCC and PCC

MCC (Motor Control Center) and PCC (Power Control Center) differ primarily in their functions: MCC is designed to control and manage electric motors while PCC focuses on distributing and controlling electrical power to various devices. MCC typically includes motor starters, overload relays, and variable frequency drives, whereas PCC contains circuit breakers and metering equipment for power distribution. Understanding these differences helps you select the right control panel for efficient motor operation or power distribution in your industrial setup.

Applications of MCC in Industry

MCC (Motor Control Center) is widely utilized in industrial environments such as manufacturing plants, oil and gas facilities, and water treatment systems for centralized motor control, monitoring, and protection. It enhances operational efficiency by enabling streamlined control of multiple motors from a single location, reducing downtime and maintenance efforts. Your facility can benefit from MCC's robust design, scalability, and ease of integration in complex industrial automation processes.

Applications of PCC in Industry

PCC (Precipitated Calcium Carbonate) is widely used in various industries such as paper manufacturing, plastics, paints, and adhesives due to its superior brightness, controlled particle size, and surface properties. Your products benefit from PCC's ability to enhance opacity, improve printability, and increase mechanical strength. Its versatile applications make PCC a preferred filler and coating pigment, optimizing performance and cost-efficiency in industrial processes.

Advantages of Using MCC

MCC (Motor Control Center) offers centralized control, simplifying maintenance and reducing wiring complexity compared to PCC (Packaged Control Center). Its modular design allows quick reconfiguration and scalability, enhancing operational flexibility for various industrial applications. You benefit from improved safety features and easier troubleshooting with MCC, leading to minimized downtime and increased productivity.

Advantages of Using PCC

Polymer Cement Concrete (PCC) offers superior durability and resistance to chemical attacks compared to traditional Modified Cement Concrete (MCC), making it ideal for harsh environmental conditions. Its enhanced bonding properties improve structural integrity and reduce maintenance costs, ensuring longer service life for your construction projects. PCC also provides better flexibility and reduced permeability, minimizing the risk of cracking and water ingress.

Comparison Chart: MCC vs PCC

MCC (Master Control Center) centralizes real-time monitoring and management of multiple Substation Automation Systems (SAS) with high reliability and scalability, while PCC (Primary Control Center) typically oversees primary power distribution focusing on local load control and protection. MCC offers advanced data aggregation, fault detection, and system-wide coordination, whereas PCC provides essential control at the feeder level with faster response times for localized incidents. Key performance metrics favor MCC for extensive grid management and analytics, whereas PCC excels in immediate operational control within a smaller geographic scope.

Factors to Consider When Choosing MCC or PCC

When choosing between Motor Control Centers (MCC) and Power Control Centers (PCC), consider the specific application requirements such as load type, control complexity, and system scalability. MCCs are ideal for motor-centric operations with multiple motor starters, while PCCs provide broader power distribution and protection for various electrical loads. Your decision should factor in maintenance needs, space constraints, and future expansion plans to ensure optimal performance and efficiency.

Future Trends in MCC and PCC Technologies

Future trends in MCC (Mobile Cloud Computing) highlight the integration of edge computing and 5G networks, enabling ultra-low latency and improved real-time data processing for mobile applications. PCC (Personal Cloud Computing) is evolving with advancements in AI-driven customization and enhanced data privacy protocols, ensuring more secure and personalized cloud services. Your mobile experience can be significantly improved as both MCC and PCC converge, offering seamless, efficient, and secure cloud-based solutions tailored to individual user needs.

MCC vs PCC Infographic

electrown.com

electrown.com