DOL starter provides a simple and cost-effective method for starting electric motors by applying full voltage directly to the motor terminals, resulting in a high starting current and torque. Star-Delta starter reduces the starting current and torque by initially connecting the motor in a star configuration before switching to a delta connection, making it suitable for applications requiring smooth starts; explore the rest of the article to understand which starter fits your needs best.

Table of Comparison

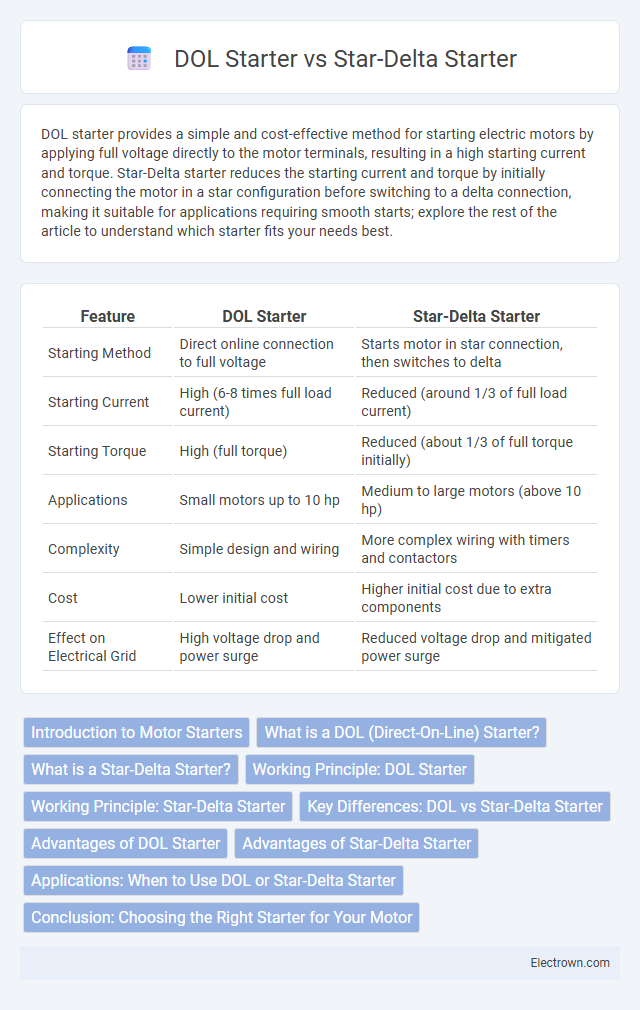

| Feature | DOL Starter | Star-Delta Starter |

|---|---|---|

| Starting Method | Direct online connection to full voltage | Starts motor in star connection, then switches to delta |

| Starting Current | High (6-8 times full load current) | Reduced (around 1/3 of full load current) |

| Starting Torque | High (full torque) | Reduced (about 1/3 of full torque initially) |

| Applications | Small motors up to 10 hp | Medium to large motors (above 10 hp) |

| Complexity | Simple design and wiring | More complex wiring with timers and contactors |

| Cost | Lower initial cost | Higher initial cost due to extra components |

| Effect on Electrical Grid | High voltage drop and power surge | Reduced voltage drop and mitigated power surge |

Introduction to Motor Starters

DOL (Direct-On-Line) starters apply full voltage directly to the motor terminals, enabling a high starting torque suitable for small motors with low starting current requirements. Star-Delta starters reduce the voltage applied during startup by initially connecting motor windings in a star configuration and then switching to delta, minimizing starting current and stress on larger motors. Both starters serve as essential motor control solutions, optimizing performance and protecting electrical systems based on motor size and load conditions.

What is a DOL (Direct-On-Line) Starter?

A DOL (Direct-On-Line) Starter is an electrical device used to start electric motors by applying the full line voltage directly to the motor terminals, ensuring maximum starting torque. It typically includes a contactor and overload relay to provide motor protection and immediate motor engagement. Compared to a Star-Delta Starter, a DOL Starter offers simplicity and robustness but results in higher starting current, which can cause mechanical stress and voltage drops in the power supply.

What is a Star-Delta Starter?

A star-delta starter is an electrical device used to reduce the starting current of a three-phase induction motor by initially connecting the motor windings in a star (Y) configuration, then switching to a delta (D) configuration for normal operation. This method limits the initial voltage applied to each winding to approximately 58% of the line voltage, significantly decreasing the starting current and mechanical stress. Star-delta starters are commonly employed in industrial applications where high starting torque is not critical and cost-effective motor starting solutions are required.

Working Principle: DOL Starter

DOL (Direct-On-Line) Starter operates by directly connecting the motor terminals to the power supply, allowing full voltage to be applied immediately for starting. This results in a high starting current, typically 6 to 8 times the full load current, making it suitable for small motors with low starting torque requirements. The simplicity of the DOL starter's working principle ensures quick and efficient motor startup without the need for complex switching mechanisms.

Working Principle: Star-Delta Starter

The Star-Delta Starter reduces the starting current by initially connecting the motor windings in a star configuration, which lowers voltage and current during startup. After a preset time, it switches the windings to a delta connection, allowing the motor to run at full voltage and speed. Your motor experiences a smooth transition from reduced to full power, minimizing mechanical stress and electrical surges.

Key Differences: DOL vs Star-Delta Starter

Direct On-Line (DOL) Starter connects the motor directly to the power supply, providing full voltage from startup, resulting in high starting current and torque. Star-Delta Starter initially connects the motor in a star configuration to reduce voltage and starting current, then switches to delta for normal running, minimizing electrical stress and mechanical shock. DOL Starters offer simplicity and cost-effectiveness, while Star-Delta Starters are preferred for reducing starting current in larger motors or systems requiring smoother startups.

Advantages of DOL Starter

DOL starters provide a simple, cost-effective solution for directly starting low-voltage motors by applying full line voltage immediately, resulting in high starting torque and minimal components. They reduce starting time and complexity compared to star-delta starters, which require additional switching and wiring configurations. DOL starters are ideal for applications demanding quick motor startups and reliable, straightforward control without the need for voltage transitions.

Advantages of Star-Delta Starter

Star-Delta Starters offer the advantage of reduced starting current, typically lowering it to one-third compared to Direct-On-Line (DOL) Starters, which helps protect electrical components and reduces the impact on power supply systems. This starter type improves motor longevity by minimizing mechanical stress during startup and enhances energy efficiency in industrial applications where high starting torque is not critical. Your choice of Star-Delta Starter can lead to smoother motor operation and cost savings in electrical infrastructure upgrades.

Applications: When to Use DOL or Star-Delta Starter

DOL starters are ideal for small motors up to 5 HP, where full voltage starting current is acceptable and simplicity is preferred, commonly used in pumps, compressors, and conveyors. Star-Delta starters suit larger motors above 5 HP that require reduced starting current to prevent electrical and mechanical stress, typical in fans, blowers, and large pumps. Selection depends on motor size, load characteristics, and grid capacity to manage inrush current effectively.

Conclusion: Choosing the Right Starter for Your Motor

DOL (Direct-On-Line) starters provide full voltage starting, ideal for small motors with low starting current, while Star-Delta starters reduce starting current by initially connecting the motor windings in star configuration before switching to delta for normal operation. Your choice depends on the motor size, load requirements, and starting current limits; DOL starters suit simple applications with available power capacity, whereas Star-Delta starters are preferred for larger motors needing smooth, low-current startup. Evaluating the specific motor characteristics and electrical supply constraints ensures selecting the most efficient and protective starting method.

DOL Starter vs Star-Delta Starter Infographic

electrown.com

electrown.com