Varistors protect electrical circuits by clamping voltage spikes through their nonlinear resistance, while gas discharge tubes safeguard by ionizing gas to divert surge currents safely to ground. Discover how each device works and which one suits Your specific surge protection needs in the full article.

Table of Comparison

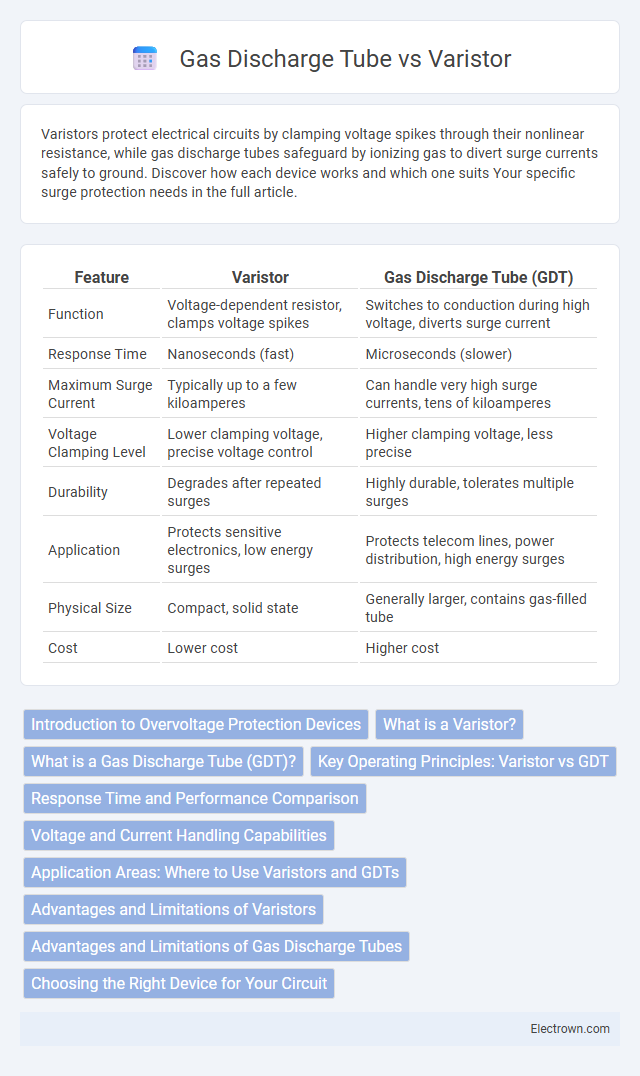

| Feature | Varistor | Gas Discharge Tube (GDT) |

|---|---|---|

| Function | Voltage-dependent resistor, clamps voltage spikes | Switches to conduction during high voltage, diverts surge current |

| Response Time | Nanoseconds (fast) | Microseconds (slower) |

| Maximum Surge Current | Typically up to a few kiloamperes | Can handle very high surge currents, tens of kiloamperes |

| Voltage Clamping Level | Lower clamping voltage, precise voltage control | Higher clamping voltage, less precise |

| Durability | Degrades after repeated surges | Highly durable, tolerates multiple surges |

| Application | Protects sensitive electronics, low energy surges | Protects telecom lines, power distribution, high energy surges |

| Physical Size | Compact, solid state | Generally larger, contains gas-filled tube |

| Cost | Lower cost | Higher cost |

Introduction to Overvoltage Protection Devices

Overvoltage protection devices such as varistors and gas discharge tubes play critical roles in safeguarding electrical and electronic circuits from voltage spikes. Varistors, composed of metal oxide semiconductor materials, offer fast response times and nonlinear voltage-dependent resistance to clamp transient voltages. Gas discharge tubes protect circuits by ionizing gas within a sealed chamber to divert high voltage surges safely to the ground, making them ideal for high-energy transient suppression.

What is a Varistor?

A varistor is an electronic component that protects circuits by clamping high voltage surges and dissipating excess energy, primarily made from metal oxide materials, often zinc oxide. Its nonlinear resistance decreases sharply when voltage exceeds a certain threshold, safeguarding your sensitive electronics from transient voltage spikes. Unlike gas discharge tubes, varistors respond faster to surges but have a limited energy absorption capacity.

What is a Gas Discharge Tube (GDT)?

A Gas Discharge Tube (GDT) is a surge protection device that utilizes ionized gas to conduct and divert excessive voltage away from sensitive electronic circuits. Unlike a varistor, which relies on metal oxide semiconductors to clamp voltage, GDTs provide a high-energy surge suppression with fast response times and the ability to handle high surge currents. Commonly used in telecommunication and power applications, GDTs protect equipment from transient voltage spikes caused by lightning or electrical faults.

Key Operating Principles: Varistor vs GDT

Varistors operate based on their nonlinear resistance property, where their resistance rapidly decreases when the voltage exceeds a certain threshold, clamping transient voltage spikes by absorbing excess energy. Gas Discharge Tubes (GDTs) function by ionizing the gas inside the tube when voltage surpasses the breakdown voltage, creating a low-resistance path that diverts high-energy surges away from sensitive components. Varistors respond more quickly to transient spikes but are limited in energy capacity, while GDTs handle higher energy surges with slower response times, making them complementary technologies in surge protection systems.

Response Time and Performance Comparison

Varistors typically have a faster response time in the nanosecond range, making them highly effective for clamping transient voltage spikes quickly, while gas discharge tubes (GDTs) respond in microseconds, suitable for high-energy surge protection but slower in reaction. Varistors offer superior performance for frequent, low-energy surges due to their rapid response and voltage-dependent resistance, whereas GDTs excel in handling high-voltage, high-energy surges with minimal leakage current and longer lifespan under extreme conditions. Choosing between them depends on the specific application's surge characteristics, with varistors optimized for fast transient suppression and GDTs providing robust protection against large surge currents.

Voltage and Current Handling Capabilities

Varistors typically handle voltage ranges from a few volts up to around 1,500 volts and are designed to absorb transient currents up to several kiloamperes in short bursts. Gas Discharge Tubes (GDTs) operate effectively at higher voltages, often between 90 volts and 10,000 volts, and can conduct surge currents exceeding 20 kiloamperes, making them suitable for high-energy transient suppression. The voltage clamping of varistors is faster but at lower energy levels, whereas GDTs provide robust protection against high-energy surges with slower response times.

Application Areas: Where to Use Varistors and GDTs

Varistors excel in protecting sensitive electronic circuits from transient voltage spikes commonly found in consumer electronics, automotive systems, and telecommunications due to their rapid response and low clamping voltage. Gas Discharge Tubes (GDTs) are preferred for high-energy surge protection in power distribution, industrial equipment, and lightning protection systems because of their ability to handle large transient currents and withstand extreme surge events. Selecting between varistors and GDTs depends on application-specific needs such as voltage rating, response time, and energy absorption capacity.

Advantages and Limitations of Varistors

Varistors offer fast response times and compact size, making them efficient for protecting electronic circuits from voltage spikes. Their key limitation is a limited energy absorption capacity and potential degradation over repeated surges. You can rely on varistors for low to moderate transient voltage suppression but may need alternative solutions like gas discharge tubes for higher-energy applications.

Advantages and Limitations of Gas Discharge Tubes

Gas Discharge Tubes (GDTs) offer superior high-energy surge protection and excellent longevity compared to varistors, handling large transient currents with minimal degradation over time. Their slower response time and larger physical size may limit applications requiring rapid clamping and compact design. Your choice of surge protection should weigh GDTs' robust energy dissipation and durability against these response and space constraints.

Choosing the Right Device for Your Circuit

Choosing the right circuit protection device involves comparing varistors and gas discharge tubes based on factors like response time, voltage range, and energy absorption capacity. Varistors excel in fast transient voltage suppression with low energy ratings suitable for sensitive electronics, while gas discharge tubes handle higher voltage surges and provide better long-term durability in industrial applications. Evaluating the specific surge environment, operational voltage, and required clamping effectiveness ensures optimal performance and circuit safety.

Varistor vs Gas Discharge Tube Infographic

electrown.com

electrown.com