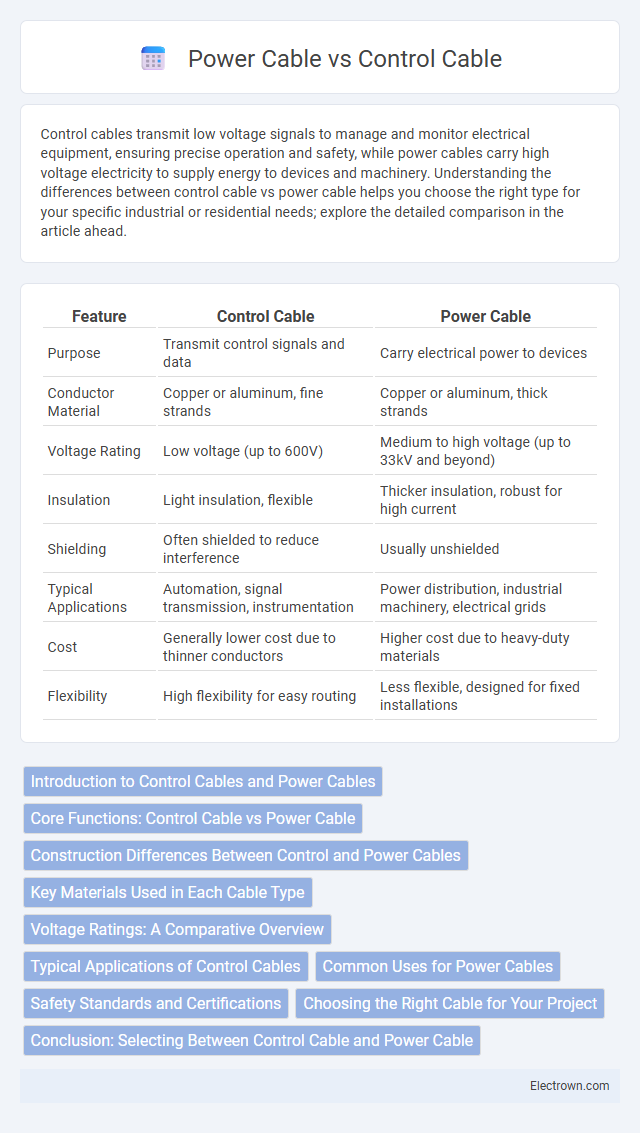

Control cables transmit low voltage signals to manage and monitor electrical equipment, ensuring precise operation and safety, while power cables carry high voltage electricity to supply energy to devices and machinery. Understanding the differences between control cable vs power cable helps you choose the right type for your specific industrial or residential needs; explore the detailed comparison in the article ahead.

Table of Comparison

| Feature | Control Cable | Power Cable |

|---|---|---|

| Purpose | Transmit control signals and data | Carry electrical power to devices |

| Conductor Material | Copper or aluminum, fine strands | Copper or aluminum, thick strands |

| Voltage Rating | Low voltage (up to 600V) | Medium to high voltage (up to 33kV and beyond) |

| Insulation | Light insulation, flexible | Thicker insulation, robust for high current |

| Shielding | Often shielded to reduce interference | Usually unshielded |

| Typical Applications | Automation, signal transmission, instrumentation | Power distribution, industrial machinery, electrical grids |

| Cost | Generally lower cost due to thinner conductors | Higher cost due to heavy-duty materials |

| Flexibility | High flexibility for easy routing | Less flexible, designed for fixed installations |

Introduction to Control Cables and Power Cables

Control cables are specialized electrical wires designed to transmit control signals in automation systems, machinery, and industrial equipment, ensuring precise operation and signal integrity. Power cables, on the other hand, are engineered to carry high voltage electrical power from sources to devices or systems, supporting energy distribution in residential, commercial, and industrial environments. Both cable types differ significantly in construction, insulation, and application, with control cables emphasizing signal clarity and power cables focusing on current capacity and durability.

Core Functions: Control Cable vs Power Cable

Control cables transmit signals and control commands within automated systems, providing precise communication between devices to ensure operational accuracy and safety. Power cables deliver electrical energy to equipment and machinery, designed to handle high voltage and current loads for efficient power distribution. While control cables emphasize signal integrity and noise resistance, power cables prioritize current-carrying capacity and thermal management.

Construction Differences Between Control and Power Cables

Control cables feature multiple fine strands of copper conductors insulated individually and grouped with additional shielding to minimize electromagnetic interference, ensuring precise signal transmission for automation systems. Power cables typically have fewer, thicker copper or aluminum conductors with robust insulation and external sheaths designed to handle higher voltages and currents for electrical distribution. Understanding these construction differences helps you select the appropriate cable for safe and efficient operation in your electrical installations.

Key Materials Used in Each Cable Type

Control cables primarily utilize copper conductors combined with PVC or XLPE insulation to ensure flexibility and resistance to environmental factors, while power cables often feature thicker copper or aluminum conductors paired with robust insulation materials like cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR) for higher voltage tolerance. The insulation and sheath materials in power cables are designed to handle greater electrical loads and thermal stresses compared to the more flexible, signal-focused construction of control cables. Choosing the right cable involves assessing the specific conductivity, insulation properties, and mechanical strength best suited for your electrical system's operational demands.

Voltage Ratings: A Comparative Overview

Control cables typically operate at lower voltage ratings, commonly ranging from 300V to 600V, designed for signal transmission and control circuits. Power cables, on the other hand, handle significantly higher voltages, often starting at 600V and extending to several kilovolts, suitable for distributing electrical power in industrial and commercial applications. Understanding the voltage rating differences between control cables and power cables ensures you select the right cable for safety and performance in your electrical system.

Typical Applications of Control Cables

Control cables are primarily used in automation systems, instrumentation, and process control applications to transmit low-voltage signals and data between control devices and equipment. They are essential in industries such as manufacturing, power plants, and HVAC systems for monitoring, controlling, and protecting machinery. These cables provide precise signal transmission with enhanced shielding to reduce electromagnetic interference in complex control circuits.

Common Uses for Power Cables

Power cables are primarily used to transmit electrical energy in residential, commercial, and industrial settings, supplying machinery, lighting, and appliances with necessary power. They come in various voltage ratings and insulation types to accommodate high current flow and environmental conditions. These cables are essential for applications demanding reliable energy delivery, including motor connections, power distribution panels, and utility services.

Safety Standards and Certifications

Control cables must comply with stringent safety standards such as UL 1277 and IEC 60228, ensuring reliable signal transmission and fire resistance in industrial environments. Power cables adhere to certifications like IEEE 1580 and NEC Article 310, designed to safely handle high voltage loads with robust insulation and thermal ratings. Both cable types require compliance with OSHA regulations to guarantee workplace safety and reduce electrical hazards.

Choosing the Right Cable for Your Project

Selecting the appropriate cable type is crucial for project efficiency and safety, with control cables designed for signal transmission and power cables intended to carry electricity. Control cables offer precise communication between machinery and control systems, featuring multiple cores and superior insulation to prevent interference. Power cables, built for high voltage loads, require robust insulation and conductor materials to ensure reliable energy delivery in industrial or residential applications.

Conclusion: Selecting Between Control Cable and Power Cable

Selecting between control cable and power cable depends primarily on their distinct functions; control cables transmit signals and manage system operations, while power cables deliver electrical energy to equipment and devices. Control cables require precise shielding and multiple conductors for signal integrity, making them essential in automation and communication systems, whereas power cables demand higher voltage ratings and insulation to safely handle electrical load. Choosing the appropriate cable type ensures system reliability, safety, and optimal performance based on the specific application's electrical and control requirements.

Control Cable vs Power Cable Infographic

electrown.com

electrown.com