Profibus DP offers high-speed communication ideal for factory automation, while Profibus PA is designed for process automation with intrinsic safety in hazardous environments and supports slower, more reliable data transmission. Explore the differences, benefits, and best use cases to determine which Profibus variant suits your specific industrial needs.

Table of Comparison

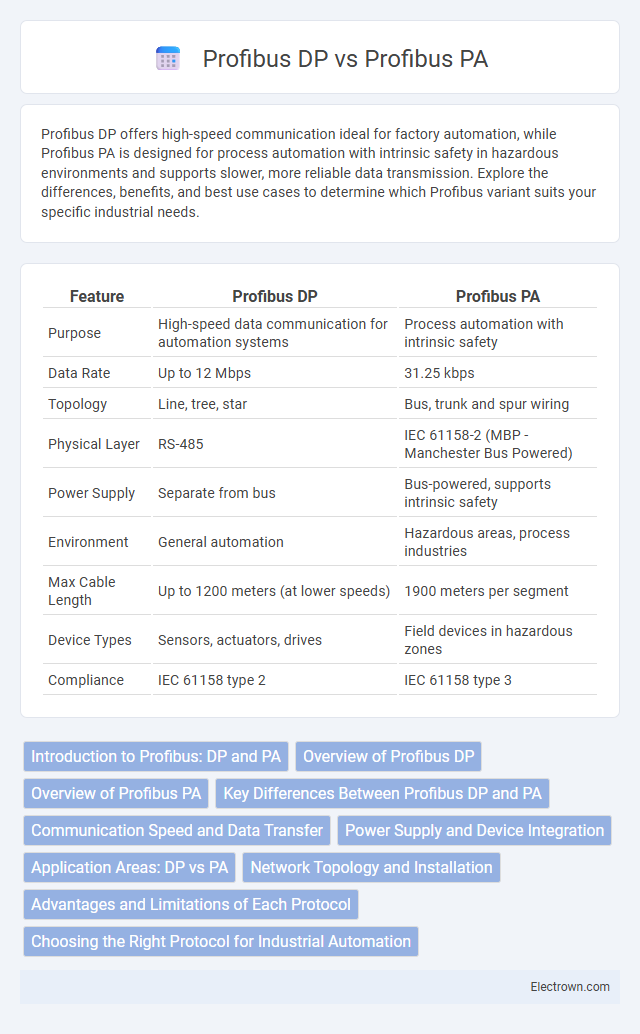

| Feature | Profibus DP | Profibus PA |

|---|---|---|

| Purpose | High-speed data communication for automation systems | Process automation with intrinsic safety |

| Data Rate | Up to 12 Mbps | 31.25 kbps |

| Topology | Line, tree, star | Bus, trunk and spur wiring |

| Physical Layer | RS-485 | IEC 61158-2 (MBP - Manchester Bus Powered) |

| Power Supply | Separate from bus | Bus-powered, supports intrinsic safety |

| Environment | General automation | Hazardous areas, process industries |

| Max Cable Length | Up to 1200 meters (at lower speeds) | 1900 meters per segment |

| Device Types | Sensors, actuators, drives | Field devices in hazardous zones |

| Compliance | IEC 61158 type 2 | IEC 61158 type 3 |

Introduction to Profibus: DP and PA

Profibus DP (Decentralized Peripherals) is designed for high-speed communication between automation systems and distributed devices in factory automation, supporting cycle times as low as 1.5 ms. Profibus PA (Process Automation) caters to process industry applications by enabling network communication and power supply over a single cable, supporting intrinsically safe environments and longer cabling distances up to 1900 meters per segment. Both protocols follow the Profibus standard but differ in their physical layers, transmission speeds, and typical use cases, optimizing connectivity for discrete production and continuous process control respectively.

Overview of Profibus DP

Profibus DP (Decentralized Peripherals) is a high-speed communication protocol designed for efficient data exchange between automation systems and distributed field devices. It operates primarily in factory automation environments, supporting cyclic data exchange with short update times and high transmission rates up to 12 Mbps. Profibus DP contrasts with Profibus PA, which is tailored for process automation with intrinsic safety and slower communication speeds suitable for hazardous areas.

Overview of Profibus PA

Profibus PA (Process Automation) is designed specifically for process industries, enabling data communication in hazardous environments with intrinsic safety standards. It supports long-distance communication and power supply through a single two-wire cable, optimizing installation costs and system reliability. Your process automation systems can benefit from Profibus PA's robust design, which facilitates real-time data exchange and device integration in complex industrial settings.

Key Differences Between Profibus DP and PA

Profibus DP (Decentralized Peripherals) is designed for high-speed communication with automation devices such as sensors and actuators, operating at data rates up to 12 Mbps and supporting a bus length of up to 1.2 km without repeaters. Profibus PA (Process Automation) is tailored for process automation environments, supporting intrinsic safety in hazardous areas with data rates of 31.25 kbps and powering field devices via the bus. The key differences include their intended applications, data transmission speeds, power supply capabilities, and suitability for hazardous environments, with Profibus DP optimized for fast, high-volume data exchange and Profibus PA optimized for safe, reliable communication in process control settings.

Communication Speed and Data Transfer

Profibus DP operates at high communication speeds up to 12 Mbps, making it ideal for fast data transfer in automation systems requiring rapid response times. Profibus PA, designed for process automation, supports slower communication speeds up to 31.25 kbps, prioritizing intrinsic safety and reliable data transmission in hazardous environments. Your choice between Profibus DP and PA depends on whether high-speed data exchange or safe, stable communication in explosive atmospheres is the primary requirement.

Power Supply and Device Integration

Profibus DP (Decentralized Peripherals) uses a separate power supply for devices, typically 24V DC, allowing faster data transmission rates up to 12 Mbps for high-speed communication with sensors and actuators. Profibus PA (Process Automation) integrates power and communication on a single twisted-pair cable, operating at 31.25 kbps, specifically designed for hazardous areas and intrinsically safe device connection. This combined power and data approach in Profibus PA enables simplified device integration and conformity with process industry safety standards.

Application Areas: DP vs PA

Profibus DP is optimized for high-speed data communication in automation systems such as manufacturing assembly lines, robotics, and process control requiring rapid data exchange. Profibus PA is designed for process automation environments like chemical plants and oil refineries, supporting intrinsic safety and power supply over the same cable for field devices in hazardous areas. Your choice between Profibus DP and PA should consider the specific application area's speed requirements and environmental constraints.

Network Topology and Installation

Profibus DP networks utilize a linear bus topology enabling high-speed communication with devices in factory automation, typically using RS-485 cabling for easy installation and flexibility. Profibus PA employs a bus topology designed for hazardous environments, integrating power and data transmission over a two-wire trunk, supporting intrinsic safety and longer cable lengths. Installation of Profibus PA often requires specialized process instrumentation cabling and compliance with explosion-proof standards, contrasting with the simpler RS-485 wiring of Profibus DP.

Advantages and Limitations of Each Protocol

Profibus DP offers high-speed data transmission ideal for factory automation, enabling fast communication between controllers and distributed I/O devices, but it is limited by its susceptibility to electrical noise and shorter cable lengths. Profibus PA excels in process automation environments with intrinsic safety features and longer cable distances, supporting device-level communication in hazardous areas, though it operates at lower data rates compared to DP. Your choice depends on whether speed and network efficiency (DP) or safety and extended reach (PA) are prioritized within your industrial setup.

Choosing the Right Protocol for Industrial Automation

Profibus DP is optimized for high-speed data exchange between controllers and field devices in factory automation environments, enabling rapid process control and diagnostics. Profibus PA is designed for process automation with intrinsic safety features, allowing communication in hazardous areas while supporting device configuration and monitoring. Your choice hinges on whether your industrial application prioritizes speed and performance (Profibus DP) or safety and robustness in hazardous locations (Profibus PA).

Profibus DP vs Profibus PA Infographic

electrown.com

electrown.com