Ex d and Ex e enclosures are both designed to prevent ignition in explosive environments, with Ex d providing a flameproof design that contains internal explosions, while Ex e offers increased safety by preventing arcs or sparks from entering the environment. Understanding the distinctions between these explosion proof standards is essential for ensuring Your equipment complies with safety regulations--continue reading to explore how to select the right enclosure for your hazardous area.

Table of Comparison

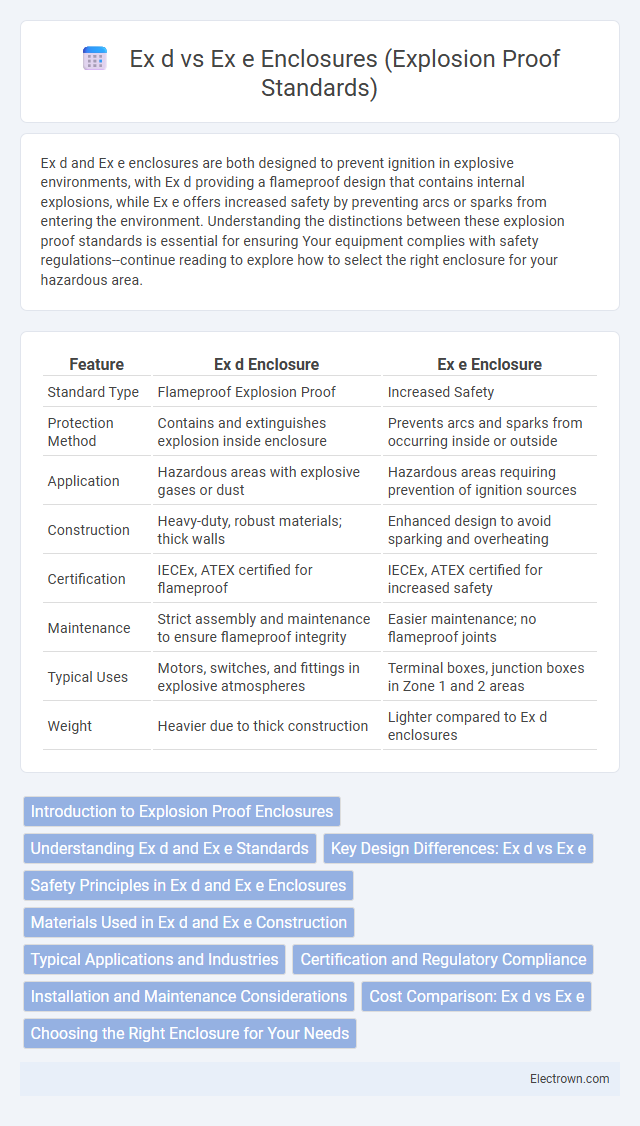

| Feature | Ex d Enclosure | Ex e Enclosure |

|---|---|---|

| Standard Type | Flameproof Explosion Proof | Increased Safety |

| Protection Method | Contains and extinguishes explosion inside enclosure | Prevents arcs and sparks from occurring inside or outside |

| Application | Hazardous areas with explosive gases or dust | Hazardous areas requiring prevention of ignition sources |

| Construction | Heavy-duty, robust materials; thick walls | Enhanced design to avoid sparking and overheating |

| Certification | IECEx, ATEX certified for flameproof | IECEx, ATEX certified for increased safety |

| Maintenance | Strict assembly and maintenance to ensure flameproof integrity | Easier maintenance; no flameproof joints |

| Typical Uses | Motors, switches, and fittings in explosive atmospheres | Terminal boxes, junction boxes in Zone 1 and 2 areas |

| Weight | Heavier due to thick construction | Lighter compared to Ex d enclosures |

Introduction to Explosion Proof Enclosures

Explosion proof enclosures are designed to contain any internal explosions and prevent ignition of surrounding hazardous atmospheres, complying with standards such as IECEx and ATEX. Ex d enclosures use a robust, flameproof design that withstands internal explosions by quenching flames within the enclosure, suitable for gases and vapors. Ex e enclosures employ increased safety measures with enhanced insulation and avoidance of sparks but do not contain explosions, making them ideal for non-arcing electrical components in hazardous environments.

Understanding Ex d and Ex e Standards

Ex d enclosures, designed for explosion-proof protection, are built to contain any internal explosion without causing external ignition, meeting stringent IECEx and ATEX certifications. Ex e enclosures use increased safety measures to prevent sparks or excessive heat under normal operation, complying with strict international explosion prevention standards. Selecting between Ex d and Ex e depends on the specific hazardous environment, operational risks, and compliance requirements in industries such as oil and gas, chemical processing, and mining.

Key Design Differences: Ex d vs Ex e

Ex d enclosures use a flameproof design that contains any internal explosion by withstanding high pressure and preventing flame escape. Ex e enclosures employ increased safety by eliminating sparks and hot surfaces, ensuring no dangerous thermal or electrical arcs occur under normal operation. Your choice depends on whether containment of an explosion or prevention of ignition sources aligns better with your hazardous area requirements.

Safety Principles in Ex d and Ex e Enclosures

Ex d enclosures utilize a flameproof design that contains and cools any internal explosion to prevent ignition of the external atmosphere, ensuring safety in hazardous environments. Ex e enclosures rely on increased safety measures, such as enhanced insulation and secure components, to prevent sparks or overheating that could ignite flammable gases. Both standards are critical in hazardous area classification, but Ex d emphasizes explosion containment while Ex e focuses on avoiding the creation of an explosive atmosphere.

Materials Used in Ex d and Ex e Construction

Ex d enclosures, designed for flameproof protection, commonly utilize robust materials such as cast aluminum, stainless steel, or copper-free aluminum to withstand high pressure and prevent flame propagation. Ex e enclosures, engineered for increased safety through enhanced electrical component isolation, often use lighter materials like polycarbonate, fiberglass, or aluminum alloy to maintain durability while facilitating heat dissipation. Material selection in both Ex d and Ex e constructions is critical to compliance with IEC 60079 standards, ensuring resistance to harsh industrial environments and explosion hazards.

Typical Applications and Industries

Ex d enclosures provide robust explosion-proof protection by containing any internal explosions, making them ideal for hazardous industries such as oil and gas, chemical plants, and mining where flammable gases and vapors are prevalent. Ex e enclosures offer increased safety through enhanced safety design rather than explosion containment, commonly used in industries like food processing, pharmaceuticals, and manufacturing where the risk of explosive atmospheres is moderate and mechanical robustness is essential. Both types comply with stringent international standards such as IEC 60079, ensuring safe operation in potentially explosive environments.

Certification and Regulatory Compliance

Ex d (flameproof) and Ex e (increased safety) enclosures differ significantly in certification and regulatory compliance, with Ex d enclosures certified to contain an internal explosion and withstand external pressure while preventing flame transmission. Ex e enclosures, on the other hand, focus on preventing the occurrence of sparks and hot surfaces, adhering to stricter component-level quality requirements to meet electrical safety standards. Your choice between Ex d and Ex e must align with specific hazardous area classifications and relevant international standards such as IECEx and ATEX certifications.

Installation and Maintenance Considerations

Ex d enclosures, designed for flameproof containment, require careful sealing and periodic inspection to ensure joint integrity and prevent gas ingress during installation and maintenance. Ex e enclosures, featuring increased safety with non-sparking components, allow easier access for routine checks and component replacement without compromising explosion protection. Proper adherence to certification guidelines and use of qualified personnel is critical for both types to maintain compliance with IEC and ATEX explosion-proof standards.

Cost Comparison: Ex d vs Ex e

Ex d enclosures, designed for flameproof protection, typically incur higher costs due to their robust construction and stringent testing requirements to withstand internal explosions. Ex e enclosures, providing increased safety through enhanced structural strengthening without containing an internal explosion, are generally more cost-effective and easier to manufacture. Budget considerations often favor Ex e solutions in less hazardous zones, while Ex d remains essential where maximum explosion containment is mandated.

Choosing the Right Enclosure for Your Needs

Ex d enclosures provide flameproof protection by containing and extinguishing internal explosions, making them ideal for hazardous environments with explosive gases or vapors. Ex e enclosures focus on increased safety by preventing ignitable sparks and heat, suitable for areas requiring enhanced electrical safety without potential internal explosion hazards. Choosing the right enclosure depends on your specific risk assessment, environment classification, and the level of explosion protection required to ensure operational safety and compliance with relevant standards.

Ex d vs Ex e Enclosures (explosion proof standards) Infographic

electrown.com

electrown.com