Soft PLC offers greater flexibility by running programmable logic control software on standard computers, allowing easy updates and scalability, while Hard PLC involves dedicated hardware designed for robust, real-time industrial control with higher reliability. Discover which solution best fits Your automation needs by exploring the detailed comparison in the rest of this article.

Table of Comparison

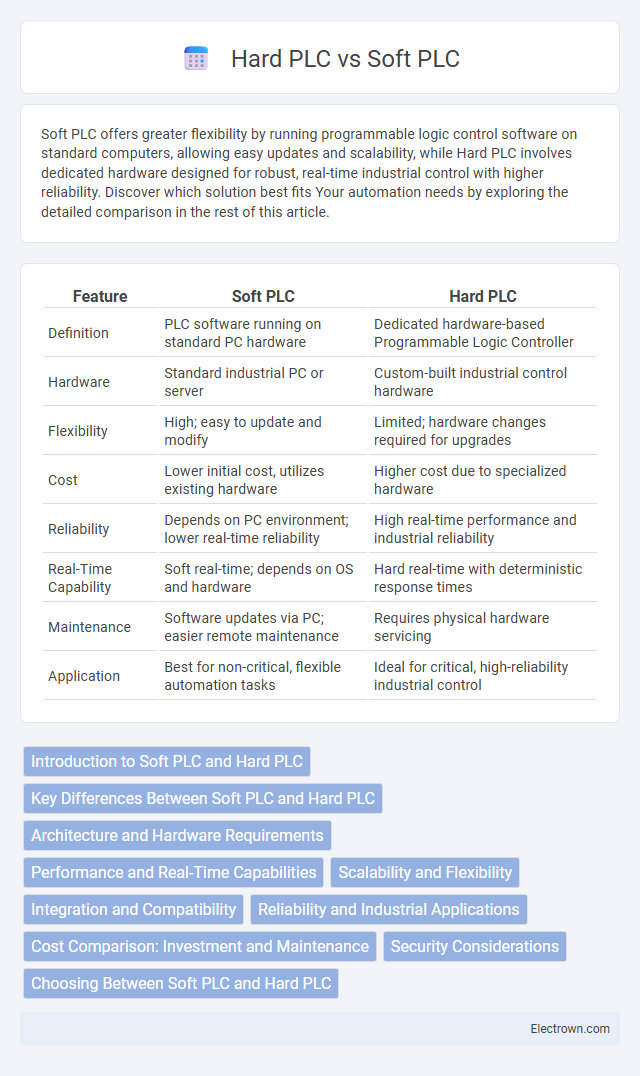

| Feature | Soft PLC | Hard PLC |

|---|---|---|

| Definition | PLC software running on standard PC hardware | Dedicated hardware-based Programmable Logic Controller |

| Hardware | Standard industrial PC or server | Custom-built industrial control hardware |

| Flexibility | High; easy to update and modify | Limited; hardware changes required for upgrades |

| Cost | Lower initial cost, utilizes existing hardware | Higher cost due to specialized hardware |

| Reliability | Depends on PC environment; lower real-time reliability | High real-time performance and industrial reliability |

| Real-Time Capability | Soft real-time; depends on OS and hardware | Hard real-time with deterministic response times |

| Maintenance | Software updates via PC; easier remote maintenance | Requires physical hardware servicing |

| Application | Best for non-critical, flexible automation tasks | Ideal for critical, high-reliability industrial control |

Introduction to Soft PLC and Hard PLC

Soft PLC operates as software on standard industrial PCs, offering flexible and cost-effective control solutions by leveraging common hardware platforms. Hard PLC refers to traditional, dedicated programmable logic controllers with specialized hardware designed for high reliability, real-time processing, and rugged environments. Comparing Soft PLC and Hard PLC highlights differences in deployment versatility, scalability, and hardware dependency in industrial automation.

Key Differences Between Soft PLC and Hard PLC

Soft PLC operates on standard industrial PCs or embedded systems using software-based control, offering flexibility and easy updates, whereas Hard PLC uses dedicated hardware modules designed for specific tasks, ensuring high reliability and real-time performance. Soft PLC allows integration with IT systems and supports complex algorithms, while Hard PLC excels in harsh industrial environments with robust physical components. The key difference lies in Soft PLC's adaptability and cost-effectiveness versus Hard PLC's durability and deterministic execution.

Architecture and Hardware Requirements

Soft PLC operates on standard industrial PCs or embedded systems, utilizing software to emulate traditional PLC functions with flexible, modular architecture and minimal dedicated hardware. Hard PLC involves specialized hardware components including processor, input/output modules, and communication interfaces designed specifically for real-time control tasks, ensuring robust performance and reliability. Soft PLC requires less physical space and offers easier integration with IT systems, whereas Hard PLC demands tailored hardware infrastructure for stringent industrial environments and deterministic response times.

Performance and Real-Time Capabilities

Hard PLCs offer superior performance and real-time capabilities due to dedicated hardware designed for fast and deterministic processing, ensuring minimal latency and high reliability in critical industrial automation tasks. Soft PLCs run on general-purpose computer platforms, which can introduce variability in processing times and limit real-time responsiveness, making them less suitable for high-speed or safety-critical applications. The choice between Soft and Hard PLCs depends on the specific performance requirements and real-time constraints of the control system.

Scalability and Flexibility

Soft PLC offers superior scalability and flexibility by running on standard industrial PCs, allowing easy upgrades and integration with various systems through software modifications. Hard PLCs provide robust real-time control with fixed hardware configurations, limiting flexibility but ensuring reliability in harsh environments. Soft PLCs excel in applications requiring frequent changes and expansion, while Hard PLCs are preferred for stable, high-performance tasks.

Integration and Compatibility

Soft PLC systems offer superior integration capabilities with IT infrastructure and support diverse programming languages, enabling seamless compatibility with modern industrial automation protocols like OPC UA and MQTT. Hard PLCs, designed with dedicated hardware, excel in real-time processing and reliability but often face limitations in integrating with non-proprietary systems and adapting to evolving communication standards. Choosing between Soft and Hard PLCs depends on the specific application requirements for system interoperability and legacy device compatibility.

Reliability and Industrial Applications

Soft PLCs offer flexible software-based control but may face reliability challenges in harsh industrial environments due to dependency on general-purpose hardware and operating systems. Hard PLCs are specifically designed with dedicated hardware, ensuring high reliability and robustness for critical industrial applications such as manufacturing automation, process control, and safety systems. Industries prioritize hard PLCs for environments requiring consistent uptime, precise timing, and resistance to electrical noise, temperature variations, and mechanical stress.

Cost Comparison: Investment and Maintenance

Soft PLCs typically offer lower initial investment costs due to their reliance on standard industrial PCs or servers instead of specialized hardware, significantly reducing upfront expenses. Maintenance costs for Soft PLCs are often lower since software updates and troubleshooting can be managed remotely, minimizing downtime and on-site service fees. In contrast, Hard PLCs require higher capital investment for proprietary hardware and incur increased maintenance costs related to physical component replacements and specialized technician support.

Security Considerations

Soft PLCs present unique security challenges due to their reliance on general-purpose operating systems, increasing exposure to malware and unauthorized access compared to Hard PLCs, which operate on dedicated hardware with limited attack surfaces. Network segmentation and robust firewall settings are essential to protect Soft PLCs from cyber threats, while Hard PLCs benefit from inherent isolation but still require secure communication protocols to prevent intrusion. Implementing regular software updates and real-time monitoring enhances the security posture of both Soft and Hard PLC systems in industrial environments.

Choosing Between Soft PLC and Hard PLC

Choosing between Soft PLC and Hard PLC depends on the application's flexibility and hardware dependency requirements. Soft PLCs offer software-based control on standard PCs, enabling easy updates and integration with IT systems, while Hard PLCs provide dedicated, reliable hardware designed for real-time industrial automation with decreased latency. Consider factors such as system scalability, environment robustness, and cost-effectiveness when selecting the appropriate PLC solution.

Soft PLC vs Hard PLC Infographic

electrown.com

electrown.com