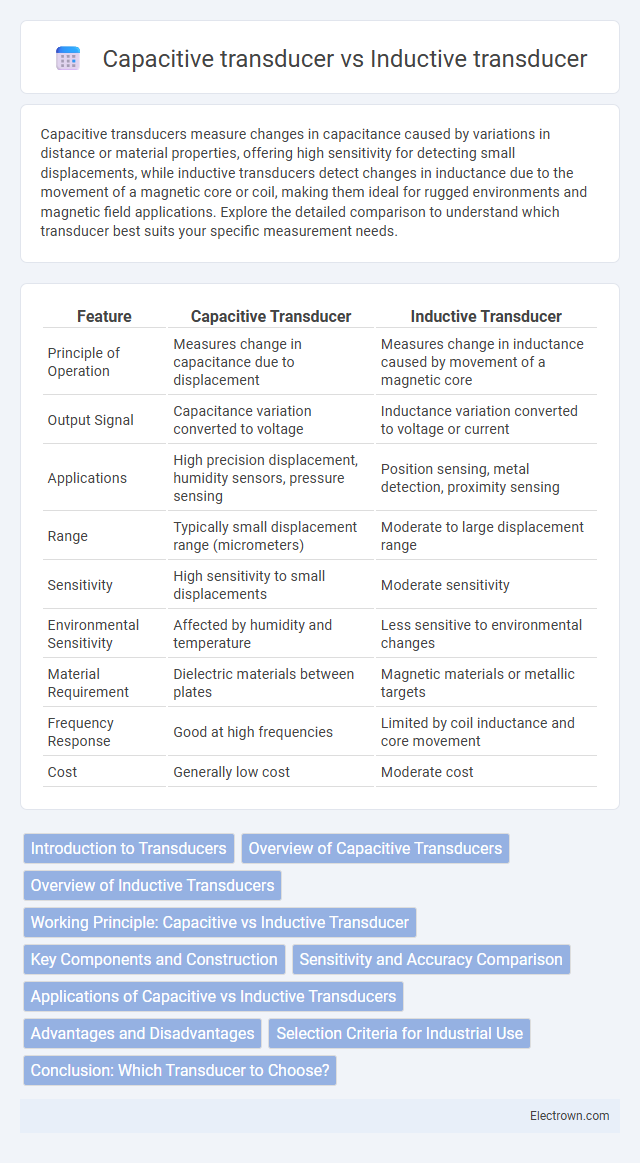

Capacitive transducers measure changes in capacitance caused by variations in distance or material properties, offering high sensitivity for detecting small displacements, while inductive transducers detect changes in inductance due to the movement of a magnetic core or coil, making them ideal for rugged environments and magnetic field applications. Explore the detailed comparison to understand which transducer best suits your specific measurement needs.

Table of Comparison

| Feature | Capacitive Transducer | Inductive Transducer |

|---|---|---|

| Principle of Operation | Measures change in capacitance due to displacement | Measures change in inductance caused by movement of a magnetic core |

| Output Signal | Capacitance variation converted to voltage | Inductance variation converted to voltage or current |

| Applications | High precision displacement, humidity sensors, pressure sensing | Position sensing, metal detection, proximity sensing |

| Range | Typically small displacement range (micrometers) | Moderate to large displacement range |

| Sensitivity | High sensitivity to small displacements | Moderate sensitivity |

| Environmental Sensitivity | Affected by humidity and temperature | Less sensitive to environmental changes |

| Material Requirement | Dielectric materials between plates | Magnetic materials or metallic targets |

| Frequency Response | Good at high frequencies | Limited by coil inductance and core movement |

| Cost | Generally low cost | Moderate cost |

Introduction to Transducers

Capacitive transducers measure changes in capacitance caused by variations in displacement, pressure, or humidity, making them ideal for precise, non-contact sensing applications. Inductive transducers operate based on changes in inductance resulting from the movement of a ferromagnetic core or coil, offering robust performance in harsh environments with high frequency response. Both transducer types convert physical quantities into electrical signals, enabling accurate measurement in automation, instrumentation, and control systems.

Overview of Capacitive Transducers

Capacitive transducers measure changes in capacitance caused by displacement, pressure, or humidity variations, employing two conductive plates separated by a dielectric. They offer high sensitivity, low power consumption, and excellent linearity, making them ideal for precise measurements in applications such as pressure sensors, humidity detectors, and accelerometers. Common materials for the dielectric include air, plastics, or ceramics, facilitating customization based on environmental conditions and required sensitivity levels.

Overview of Inductive Transducers

Inductive transducers convert mechanical displacement into electrical signals by altering the inductance of a coil, commonly used in position and proximity sensing. These devices rely on changes in magnetic flux caused by the movement of a ferromagnetic core or variations in the coil's inductive properties. Inductive transducers offer high sensitivity, durability, and immunity to environmental contaminants, making them ideal for industrial automation and control systems.

Working Principle: Capacitive vs Inductive Transducer

Capacitive transducers operate based on the variation in capacitance caused by changes in the distance between two conductive plates or the dielectric material between them, allowing precise measurement of displacement and pressure. Inductive transducers rely on changes in inductance, typically through wire coils or magnetic cores, when a ferromagnetic material or coil position shifts relative to the magnetic field, making them ideal for measuring linear or angular motion. Your choice between capacitive and inductive transducers depends on the specific application requirements for sensitivity, range, and environmental conditions.

Key Components and Construction

Capacitive transducers primarily consist of two conductive plates separated by a dielectric material, where changes in capacitance occur due to variations in distance or dielectric constant. Inductive transducers feature a coil and a movable ferromagnetic core, with inductance changes caused by core position or magnetic permeability. Your choice depends on the required sensitivity, frequency response, and environmental conditions, as capacitive types excel in measuring small displacements while inductive types are robust for detecting metal objects or larger mechanical movements.

Sensitivity and Accuracy Comparison

Capacitive transducers exhibit higher sensitivity due to their ability to detect minute changes in capacitance caused by displacement or pressure variations, making them ideal for precision measurements. Inductive transducers offer robust accuracy in environments with electromagnetic interference, relying on variations in inductance that are less affected by external noise. Your choice between these depends on whether high sensitivity or environmental accuracy holds greater importance in your application.

Applications of Capacitive vs Inductive Transducers

Capacitive transducers are widely used in applications requiring precise measurement of displacement, humidity, and pressure due to their high sensitivity and ability to detect changes in dielectric constant. Inductive transducers find extensive use in industrial automation and position sensing, especially in harsh environments, because of their robustness, high accuracy, and immunity to dirt and temperature variations. Both types are critical in robotics, automotive sensors, and aerospace systems, but capacitive sensors excel in micro-scale measurements while inductive sensors dominate in heavy machinery monitoring.

Advantages and Disadvantages

Capacitive transducers offer high sensitivity and can detect changes in displacement, pressure, or humidity with excellent accuracy, making them ideal for precision measurements; however, they are sensitive to environmental factors like temperature and humidity, which can affect performance. Inductive transducers provide robust operation and are less affected by environmental conditions, offering durability and long-term reliability in harsh industrial settings, but they typically have lower sensitivity compared to capacitive types. Your choice depends on whether accuracy or environmental robustness is prioritized for the specific application.

Selection Criteria for Industrial Use

Capacitive transducers are ideal for measuring changes in displacement, position, or humidity with high sensitivity and are preferred in environments requiring non-contact sensing and high-resolution measurements. Inductive transducers excel in harsh industrial settings due to their robustness, resistance to dust, moisture, and electromagnetic interference, making them suitable for position and metal detection applications. Your choice between these transducers should consider factors like environmental conditions, required measurement accuracy, target material, and sensitivity to ensure optimal performance in industrial use.

Conclusion: Which Transducer to Choose?

Capacitive transducers offer high sensitivity and accuracy ideal for detecting small changes in position or displacement, making them suitable for precision measurements. Inductive transducers excel in harsh environments with strong magnetic fields due to their robust construction and immunity to contaminants. Your choice depends on the application's specific requirements, including environmental conditions and measurement precision.

Capacitive transducer vs Inductive transducer Infographic

electrown.com

electrown.com