I2C communication uses a two-wire interface allowing multiple devices on the same bus with unique addresses, making it ideal for simple, low-speed data transfer. SPI communication employs separate lines for data and clock signals, providing faster data rates and more robust performance for Your high-speed applications; explore the rest of the article to understand which protocol best suits Your project needs.

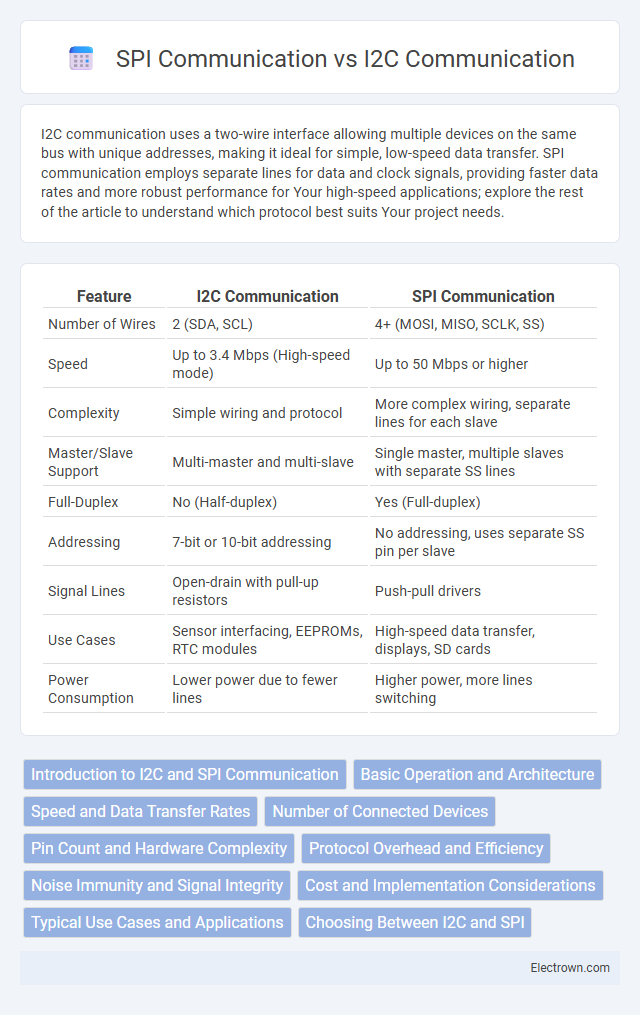

Table of Comparison

| Feature | I2C Communication | SPI Communication |

|---|---|---|

| Number of Wires | 2 (SDA, SCL) | 4+ (MOSI, MISO, SCLK, SS) |

| Speed | Up to 3.4 Mbps (High-speed mode) | Up to 50 Mbps or higher |

| Complexity | Simple wiring and protocol | More complex wiring, separate lines for each slave |

| Master/Slave Support | Multi-master and multi-slave | Single master, multiple slaves with separate SS lines |

| Full-Duplex | No (Half-duplex) | Yes (Full-duplex) |

| Addressing | 7-bit or 10-bit addressing | No addressing, uses separate SS pin per slave |

| Signal Lines | Open-drain with pull-up resistors | Push-pull drivers |

| Use Cases | Sensor interfacing, EEPROMs, RTC modules | High-speed data transfer, displays, SD cards |

| Power Consumption | Lower power due to fewer lines | Higher power, more lines switching |

Introduction to I2C and SPI Communication

I2C communication uses a two-wire interface consisting of a data (SDA) and clock (SCL) line for efficient, low-speed serial data transfer between multiple devices, ideal for sensor integration and configuration tasks. SPI communication employs four separate lines: MOSI (Master Out Slave In), MISO (Master In Slave Out), SCLK (Serial Clock), and SS (Slave Select), enabling faster, full-duplex data transfer suitable for high-speed applications like memory or display modules. Your choice between I2C and SPI depends on factors like data speed requirements, device count on the bus, and system complexity.

Basic Operation and Architecture

I2C communication operates using a two-wire interface consisting of a serial data line (SDA) and a serial clock line (SCL), enabling multiple devices to share the same bus through unique addressing and synchronized clock signals. SPI communication utilizes a four-wire protocol with separate lines for master output/slave input (MOSI), master input/slave output (MISO), serial clock (SCK), and slave select (SS), allowing full-duplex data transfer with dedicated chip select lines for each peripheral. The fundamental architecture of I2C supports multi-master and multi-slave configurations with open-drain outputs and pull-up resistors, while SPI employs a single master and multiple slaves with dedicated chip select control, typically resulting in faster data rates due to its simple hardware design.

Speed and Data Transfer Rates

I2C communication typically offers data transfer rates up to 3.4 Mbps in high-speed mode, making it suitable for moderate-speed sensor and peripheral communication. SPI communication supports significantly higher data transfer rates, often exceeding 10 Mbps, allowing for rapid data exchange in applications requiring fast real-time processing. Your choice between I2C and SPI depends on whether you prioritize simplicity and multi-device connectivity (I2C) or high-speed, full-duplex communication (SPI).

Number of Connected Devices

I2C communication supports multiple devices on the same two-wire bus by assigning unique addresses to each connected device, allowing for efficient communication with many peripherals. In contrast, SPI communication typically requires separate chip select lines for each device, limiting the practical number of connected devices due to increased wiring complexity. Your choice depends on whether you prioritize a simpler physical connection with many devices (I2C) or faster data transfer with fewer devices (SPI).

Pin Count and Hardware Complexity

I2C communication uses only two pins--SDA (data line) and SCL (clock line)--resulting in a simpler and more cost-effective hardware design compared to SPI, which requires at least four pins: MOSI (Master Out Slave In), MISO (Master In Slave Out), SCLK (Serial Clock), and SS (Slave Select). I2C's lower pin count reduces PCB complexity and wiring requirements, making it ideal for applications with multiple devices on the same bus. In contrast, SPI offers higher data transfer rates and full-duplex communication but at the expense of increased pin usage and more complex hardware layouts due to individual chip select lines for each slave device.

Protocol Overhead and Efficiency

I2C communication features a simpler two-wire protocol with inherent address overhead that slightly reduces data transmission efficiency compared to SPI, which uses a faster full-duplex four-wire interface allowing continuous data flow. SPI's lack of addressing protocol overhead and higher clock rates result in lower latency and higher throughput for large data transfers. Despite I2C's lower pin count and ease of multi-device communication, SPI generally outperforms I2C in efficiency due to minimal protocol overhead and faster clock speeds.

Noise Immunity and Signal Integrity

I2C communication typically offers better noise immunity due to its open-drain configuration and use of pull-up resistors, which help reduce signal reflections and improve reliability in electrically noisy environments. SPI communication, while faster and simpler in protocol, can be more susceptible to noise because it relies on single-ended signals and lacks built-in error checking, potentially compromising signal integrity over longer distances or in high-interference settings. For applications where maintaining data accuracy and signal quality is critical, choosing I2C can enhance your system's robustness against electromagnetic interference.

Cost and Implementation Considerations

I2C communication typically offers a lower cost solution due to its simple two-wire interface, reducing the need for multiple pins and complex PCB layouts compared to SPI, which requires separate lines for data, clock, and chip select signals. Implementing I2C involves managing device addressing and potential bus arbitration, adding software complexity but enabling communication with multiple devices on a single bus. SPI provides faster data transfer rates and simpler hardware design but may increase overall system cost and PCB complexity due to additional wiring requirements.

Typical Use Cases and Applications

I2C communication is typically used in applications requiring multiple low-speed peripherals such as sensors, EEPROMs, and RTC modules due to its simple two-wire interface and addressable devices. SPI communication is preferred in high-speed and high-throughput scenarios, including SD card interfaces, display controllers, and real-time data transfer where full-duplex communication is essential. Embedded systems often leverage I2C for inter-chip communication, while SPI is favored in microcontroller-to-peripheral connections demanding rapid data exchange and low latency.

Choosing Between I2C and SPI

I2C communication offers simplicity and requires only two wires, making it ideal for applications with multiple devices and limited pin availability, while SPI provides faster data transfer speeds and full-duplex communication with separate lines for data and clock signals. Choosing between I2C and SPI depends on factors such as required data rate, device count, and power consumption constraints. For complex systems needing high-speed communication and low latency, SPI is preferred, whereas I2C suits low-speed, simple, and cost-sensitive designs.

I2C communication vs SPI communication Infographic

electrown.com

electrown.com