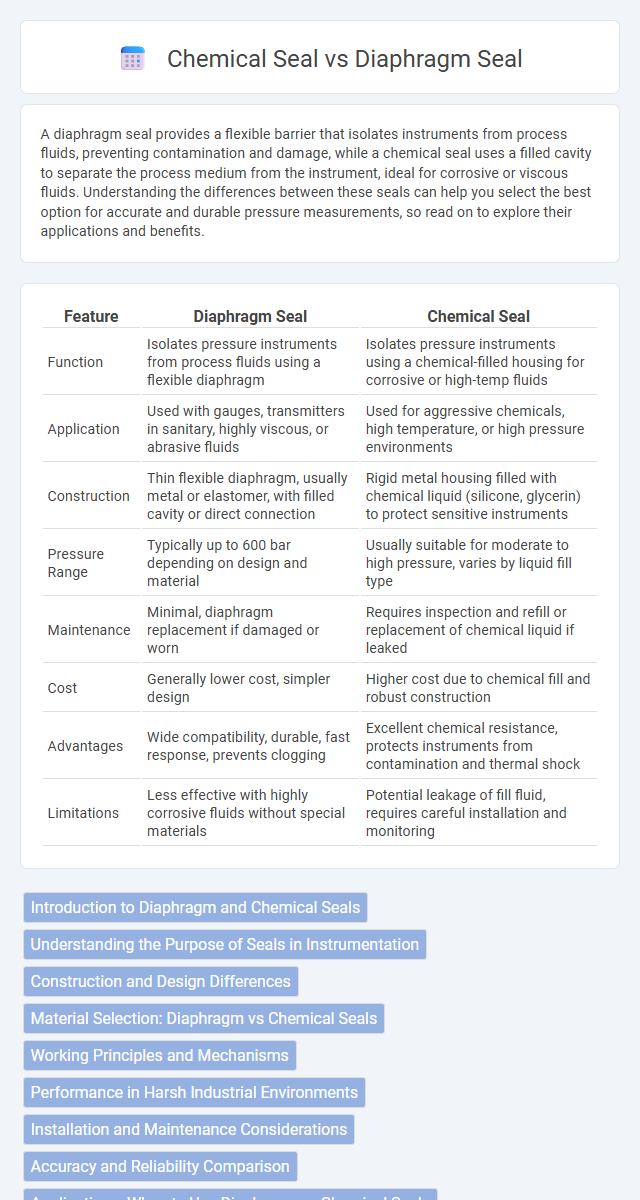

A diaphragm seal provides a flexible barrier that isolates instruments from process fluids, preventing contamination and damage, while a chemical seal uses a filled cavity to separate the process medium from the instrument, ideal for corrosive or viscous fluids. Understanding the differences between these seals can help you select the best option for accurate and durable pressure measurements, so read on to explore their applications and benefits.

Table of Comparison

| Feature | Diaphragm Seal | Chemical Seal |

|---|---|---|

| Function | Isolates pressure instruments from process fluids using a flexible diaphragm | Isolates pressure instruments using a chemical-filled housing for corrosive or high-temp fluids |

| Application | Used with gauges, transmitters in sanitary, highly viscous, or abrasive fluids | Used for aggressive chemicals, high temperature, or high pressure environments |

| Construction | Thin flexible diaphragm, usually metal or elastomer, with filled cavity or direct connection | Rigid metal housing filled with chemical liquid (silicone, glycerin) to protect sensitive instruments |

| Pressure Range | Typically up to 600 bar depending on design and material | Usually suitable for moderate to high pressure, varies by liquid fill type |

| Maintenance | Minimal, diaphragm replacement if damaged or worn | Requires inspection and refill or replacement of chemical liquid if leaked |

| Cost | Generally lower cost, simpler design | Higher cost due to chemical fill and robust construction |

| Advantages | Wide compatibility, durable, fast response, prevents clogging | Excellent chemical resistance, protects instruments from contamination and thermal shock |

| Limitations | Less effective with highly corrosive fluids without special materials | Potential leakage of fill fluid, requires careful installation and monitoring |

Introduction to Diaphragm and Chemical Seals

Diaphragm seals isolate pressure instruments from process fluids using a flexible diaphragm that transmits pressure without allowing direct contact. Chemical seals function similarly but include a fill fluid to hydraulically transmit pressure, enhancing compatibility with corrosive or high-temperature media. Both seals protect instruments from contamination and damage, ensuring accurate pressure measurement in challenging environments.

Understanding the Purpose of Seals in Instrumentation

Diaphragm seals and chemical seals serve as critical protective barriers in instrumentation, preventing corrosive, viscous, or high-temperature process fluids from damaging sensitive pressure measurement devices. Diaphragm seals utilize a flexible membrane to transmit pressure while isolating the instrument, ideal for environments with aggressive media or sanitary requirements. Chemical seals, often filled with a compatible fluid, provide a robust isolation method for instruments exposed to hazardous or crystallizing chemicals, preserving measurement accuracy and extending equipment lifespan.

Construction and Design Differences

Diaphragm seals feature a flexible, corrosion-resistant membrane that isolates the process fluid from the pressure sensor, ensuring accurate measurements in harsh environments. Chemical seals utilize a fluid-filled chamber between the process and the sensor, allowing for effective pressure transmission while protecting against corrosive or high-temperature fluids. Your selection depends on the specific process conditions and maintenance preferences related to these construction and design differences.

Material Selection: Diaphragm vs Chemical Seals

Diaphragm seals are typically made from elastomers, stainless steel, or Hastelloy, offering flexibility and corrosion resistance for various industrial applications. Chemical seals often utilize materials like 316L stainless steel, PTFE, and exotic alloys such as Monel or Inconel to withstand aggressive chemicals and high pressures. Material selection depends on compatibility with the process fluid, temperature range, and pressure conditions to ensure optimal performance and longevity.

Working Principles and Mechanisms

Diaphragm seals operate by isolating the process fluid with a flexible diaphragm that transmits pressure to a sensor filled with a compatible fill fluid, ensuring accurate measurement without direct contact with the process medium. Chemical seals, on the other hand, employ a barrier fluid contained between two flanges or seals to separate the instrument from aggressive or corrosive chemicals, protecting sensitive components from damage. Both mechanisms are designed to enhance measurement reliability and longevity in harsh industrial environments by preventing process fluid contamination and equipment corrosion.

Performance in Harsh Industrial Environments

Diaphragm seals provide superior resistance to corrosion, high temperatures, and abrasive fluids, making them ideal for harsh industrial environments. Chemical seals, while effective for isolation in corrosive media, often have limited durability under extreme pressure or temperature fluctuations. Diaphragm seals reduce maintenance frequency due to their robust design and ability to prevent process fluid contamination, ensuring reliable performance in demanding conditions.

Installation and Maintenance Considerations

Diaphragm seals offer straightforward installation with minimal space requirements and can be easily integrated with various pressure instruments, reducing downtime during setup. Chemical seals typically demand careful handling and proper alignment to ensure accurate fluid isolation, often requiring more complex installation processes. Maintenance for diaphragm seals involves routine inspection for membrane integrity, while chemical seals need regular checks for corrosion and contamination to prevent system failures.

Accuracy and Reliability Comparison

Diaphragm seals offer higher accuracy by isolating pressure sensors from process fluids, minimizing measurement errors caused by corrosive or viscous media. Chemical seals provide reliable protection in aggressive chemical environments, but their accuracy can be impacted by fluid viscosity and temperature variations. Both seals enhance system reliability, yet diaphragm seals are preferred for precise pressure readings in sensitive applications.

Applications: When to Use Diaphragm or Chemical Seals

Diaphragm seals are ideal for applications involving corrosive, viscous, or high-temperature fluids where isolation of the process media from the pressure-sensing element is critical. Chemical seals are preferred in scenarios requiring filling fluids compatible with aggressive chemicals or high-purity environments, such as pharmaceutical or semiconductor industries, ensuring accurate pressure measurement without contamination. Selection depends on factors like fluid compatibility, temperature, and pressure conditions, with diaphragm seals commonly used in general industrial processes and chemical seals favored for highly sensitive or specialized applications.

Pros, Cons, and Selection Guidelines

Diaphragm seals offer excellent leak prevention and chemical resistance, making them ideal for corrosive or viscous fluids, but they can introduce pressure measurement inaccuracies due to fill fluid effects. Chemical seals are simpler, cost-effective, and suitable for less aggressive fluids but may suffer from contamination risks and limited fluid compatibility. Select diaphragm seals for aggressive, high-pressure environments requiring isolation accuracy, and choose chemical seals when budget constraints align with non-corrosive, stable process conditions.

Diaphragm seal vs Chemical seal Infographic

electrown.com

electrown.com