Analog input modules process continuous signals such as temperature or pressure, providing precise and variable data readings, while digital input modules handle discrete signals like on/off states, offering straightforward binary input detection. Understanding the differences between these modules is essential for selecting the right option for Your control system; keep reading to explore their functionalities in detail.

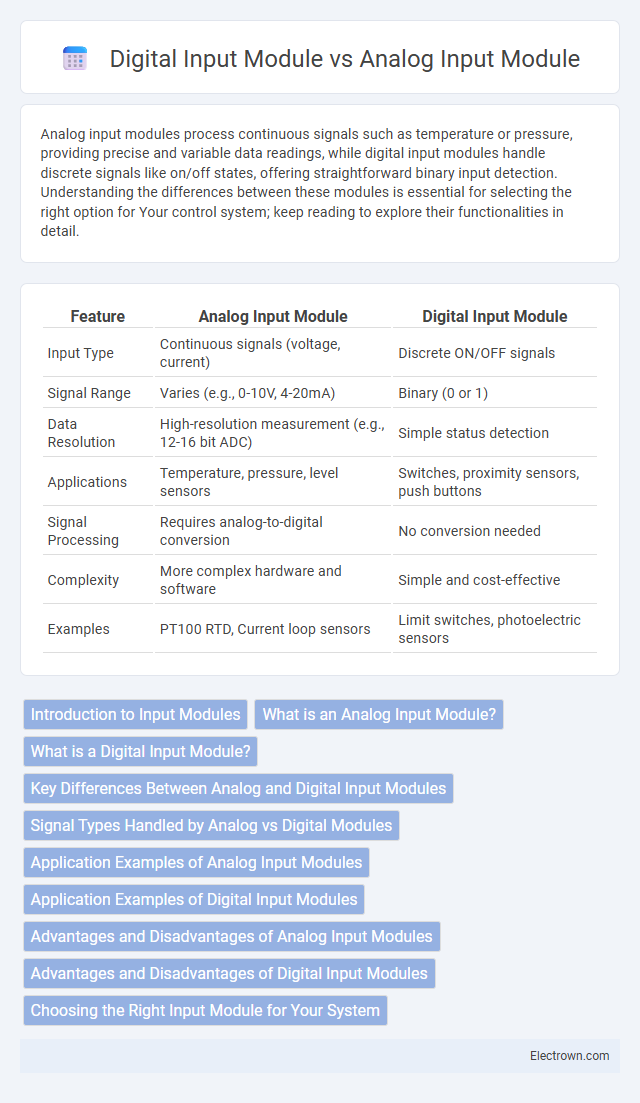

Table of Comparison

| Feature | Analog Input Module | Digital Input Module |

|---|---|---|

| Input Type | Continuous signals (voltage, current) | Discrete ON/OFF signals |

| Signal Range | Varies (e.g., 0-10V, 4-20mA) | Binary (0 or 1) |

| Data Resolution | High-resolution measurement (e.g., 12-16 bit ADC) | Simple status detection |

| Applications | Temperature, pressure, level sensors | Switches, proximity sensors, push buttons |

| Signal Processing | Requires analog-to-digital conversion | No conversion needed |

| Complexity | More complex hardware and software | Simple and cost-effective |

| Examples | PT100 RTD, Current loop sensors | Limit switches, photoelectric sensors |

Introduction to Input Modules

Input modules convert external signals into data understandable by a control system, with analog input modules processing continuous signals such as temperature or pressure, and digital input modules handling discrete signals like on/off states or switch positions. Analog input modules provide variable voltage or current data essential for precise measurement and control, while digital input modules detect binary conditions crucial for monitoring machines and safety systems. Selection depends on the nature of the input signals and the required resolution for accurate automation performance.

What is an Analog Input Module?

An Analog Input Module converts continuous electrical signals from sensors into digital data for processing within a control system, enabling precise measurement of variables like temperature, pressure, and flow. Unlike digital input modules that detect discrete ON/OFF states, analog modules handle varying voltage or current levels, typically ranging from 0-10V or 4-20mA. This capability allows for accurate monitoring and control in industrial automation, enhancing process efficiency and system responsiveness.

What is a Digital Input Module?

A digital input module detects and processes binary signals such as ON/OFF or HIGH/LOW states from field devices like switches, sensors, or relays. It converts discrete electrical inputs into programmable logic controller (PLC) readable data, enabling precise monitoring and control in automation systems. Digital input modules are essential for applications requiring status detection, fault monitoring, and simple signal processing.

Key Differences Between Analog and Digital Input Modules

Analog input modules measure continuous signals such as temperature, pressure, or voltage, providing variable data within a range, while digital input modules detect discrete on/off states or binary signals like switches and sensors. Analog inputs enable precise monitoring of real-world variables by converting physical parameters into proportional electrical values, whereas digital inputs simply register state changes or logic levels. Understanding these key differences helps you select the appropriate module for applications requiring either detailed measurement or simple status detection.

Signal Types Handled by Analog vs Digital Modules

Analog input modules handle continuous signals, such as voltage or current, which vary over a range and represent real-world parameters like temperature, pressure, or flow. Digital input modules process discrete signals, typically binary states like ON/OFF or HIGH/LOW, sourced from sensors or switches that represent distinct event occurrences. The ability of analog modules to interpret varying signal magnitudes contrasts with digital modules' focus on detecting specific logic levels or contact states.

Application Examples of Analog Input Modules

Analog input modules are essential in applications requiring precise measurement of variables like temperature, pressure, and flow, common in industrial automation and process control systems. Devices such as thermocouples, RTDs, and pressure transducers provide continuous variable signals to analog input modules for real-time monitoring and control. Your system benefits from enhanced accuracy and responsiveness when integrating analog input modules to capture subtle changes in sensor data compared to digital input modules that handle only discrete on/off signals.

Application Examples of Digital Input Modules

Digital input modules are widely used in industrial automation systems to monitor the status of equipment such as push buttons, limit switches, and proximity sensors. These modules excel in applications requiring binary signal detection, like conveyor belt presence detection, emergency stop circuits, and machine start/stop controls. Your control system benefits from real-time monitoring and fast response due to the clear ON/OFF signal processing of digital input modules.

Advantages and Disadvantages of Analog Input Modules

Analog input modules offer precise measurement of varying signals such as temperature, pressure, and voltage, enabling detailed monitoring and control in complex industrial systems. They can capture continuous data, providing richer information than digital input modules, which only read discrete on/off states. However, analog modules are more susceptible to noise interference, requiring careful calibration and maintenance, which might increase your system's complexity and cost.

Advantages and Disadvantages of Digital Input Modules

Digital input modules offer fast and reliable signal processing ideal for binary status detection in industrial automation. Their advantages include simple wiring, reduced noise susceptibility, and easy integration with programmable logic controllers (PLCs). However, digital input modules are limited to on/off signals and cannot measure variable data, which restricts their application in processes requiring precise analog measurements.

Choosing the Right Input Module for Your System

Choosing the right input module for your system depends on the type of data to be processed: analog input modules capture continuous signals such as temperature, pressure, or voltage levels, while digital input modules handle discrete signals like on/off states or binary conditions. Analog modules offer precise measurement and variable data representation, essential for applications requiring fine control or monitoring. Digital modules are simpler, faster, and ideal for detecting the presence or absence of signals or switches within automation and control environments.

analog input module vs digital input module Infographic

electrown.com

electrown.com