Contact-based sensors require physical interaction with the object to measure parameters such as temperature, pressure, or humidity, offering accurate and direct readings. Non-contact sensors detect properties from a distance using methods like infrared or ultrasonic waves, providing safer and faster measurements without surface interference; explore the differences and applications of both sensor types in the full article.

Table of Comparison

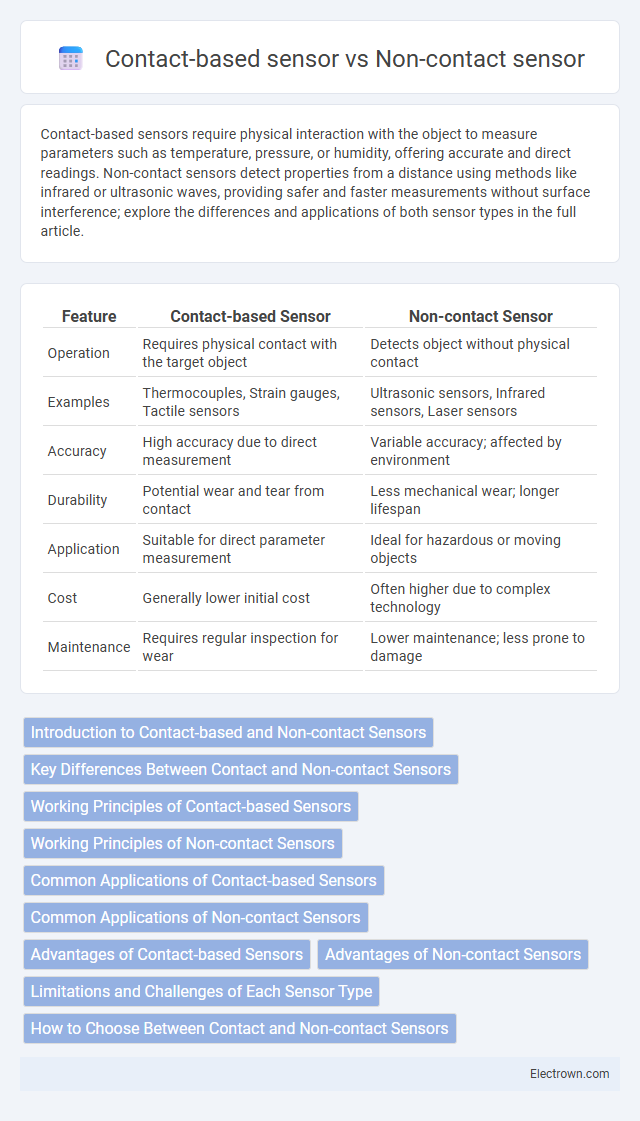

| Feature | Contact-based Sensor | Non-contact Sensor |

|---|---|---|

| Operation | Requires physical contact with the target object | Detects object without physical contact |

| Examples | Thermocouples, Strain gauges, Tactile sensors | Ultrasonic sensors, Infrared sensors, Laser sensors |

| Accuracy | High accuracy due to direct measurement | Variable accuracy; affected by environment |

| Durability | Potential wear and tear from contact | Less mechanical wear; longer lifespan |

| Application | Suitable for direct parameter measurement | Ideal for hazardous or moving objects |

| Cost | Generally lower initial cost | Often higher due to complex technology |

| Maintenance | Requires regular inspection for wear | Lower maintenance; less prone to damage |

Introduction to Contact-based and Non-contact Sensors

Contact-based sensors require physical interaction with the target object to detect changes in parameters such as pressure, temperature, or displacement, making them suitable for precise and direct measurements. Non-contact sensors utilize methods like infrared, ultrasonic, or laser technology to measure without touching the object, ideal for fragile or moving targets. Your choice between these sensors depends on the application's sensitivity, environment, and accuracy requirements.

Key Differences Between Contact and Non-contact Sensors

Contact-based sensors require physical interaction with the target object to measure parameters such as temperature, pressure, or displacement, ensuring direct and typically highly accurate readings. Non-contact sensors use methods like infrared, ultrasonic, or laser technology to detect measurements from a distance, offering advantages in hygiene, safety, and the ability to monitor moving or delicate surfaces. The choice between contact and non-contact sensors depends on factors including the application environment, required measurement precision, response time, and potential interference with the target.

Working Principles of Contact-based Sensors

Contact-based sensors operate by physically touching the object or environment to detect changes in properties such as pressure, temperature, or position. These sensors convert mechanical interactions into electrical signals, enabling real-time monitoring through direct contact. Your applications benefit from their high accuracy and reliability in environments where surface interaction is feasible.

Working Principles of Non-contact Sensors

Non-contact sensors operate by detecting physical properties such as temperature, distance, or motion without physical interaction, using technologies like infrared, ultrasonic, capacitive, or inductive sensing. Infrared sensors measure emitted heat energy, while ultrasonic sensors calculate distance based on reflected sound waves. Capacitive and inductive sensors detect changes in electric or magnetic fields caused by nearby objects, enabling precise measurements without direct contact.

Common Applications of Contact-based Sensors

Contact-based sensors are widely used in industrial automation for monitoring machine parts and detecting physical changes such as pressure, temperature, and position. In healthcare, these sensors play a vital role in patient monitoring devices like blood pressure cuffs and wearable health trackers. Your choice of sensor should consider environments where direct physical interaction is necessary for accurate data collection.

Common Applications of Non-contact Sensors

Non-contact sensors are widely used in applications requiring precise measurements without physical interaction, such as industrial automation for detecting object presence, distance measurement, and quality control. They are integral in robotics for obstacle avoidance, medical devices for patient monitoring, and automotive systems for adaptive cruise control and parking assistance. Your choice of non-contact sensors enhances reliability and longevity in environments sensitive to wear or contamination.

Advantages of Contact-based Sensors

Contact-based sensors offer precise and reliable measurements by maintaining direct physical interaction with the target, ensuring higher accuracy in detecting changes such as pressure, temperature, or force. Their robustness and durability in harsh environments make them ideal for applications requiring consistent real-time data without interference from external conditions. You benefit from lower costs and simpler calibration processes compared to non-contact sensors, enhancing overall system efficiency and maintenance.

Advantages of Non-contact Sensors

Non-contact sensors offer significant advantages such as eliminating wear and tear since they do not physically touch the detected object, ensuring longer device lifespan and reduced maintenance costs. They provide high precision and can measure moving, hot, or hazardous objects safely without interrupting operations. Your applications benefit from enhanced flexibility and faster response times, making non-contact sensors ideal for diverse industrial and technological environments.

Limitations and Challenges of Each Sensor Type

Contact-based sensors face limitations such as wear and tear due to physical interaction, reduced lifespan in harsh environments, and potential interference with the measured object's dynamics. Non-contact sensors encounter challenges including sensitivity to environmental conditions like dust, temperature, and ambient light, constraints on measurement range and resolution, and increased complexity in signal processing to filter noise. Both sensor types require careful consideration of application-specific requirements to mitigate these limitations effectively.

How to Choose Between Contact and Non-contact Sensors

Choosing between contact and non-contact sensors depends on your application's environment, accuracy requirements, and object properties. Contact sensors physically touch the target, offering precise measurements for solid or stable objects, while non-contact sensors use optical, ultrasonic, or electromagnetic methods ideal for delicate, moving, or hazardous materials. Consider factors like response time, durability, maintenance, and safety to determine the best sensor type for your specific use case.

Contact-based sensor vs Non-contact sensor Infographic

electrown.com

electrown.com