Ratiometric measurement compares the ratio between two signals to provide more accurate and stable data by compensating for variables like temperature and sensor drift, whereas absolute measurement relies on a single signal value representing the exact magnitude of the parameter. Discover how choosing between ratiometric and absolute measurements can impact your application's precision and reliability by reading the full article.

Table of Comparison

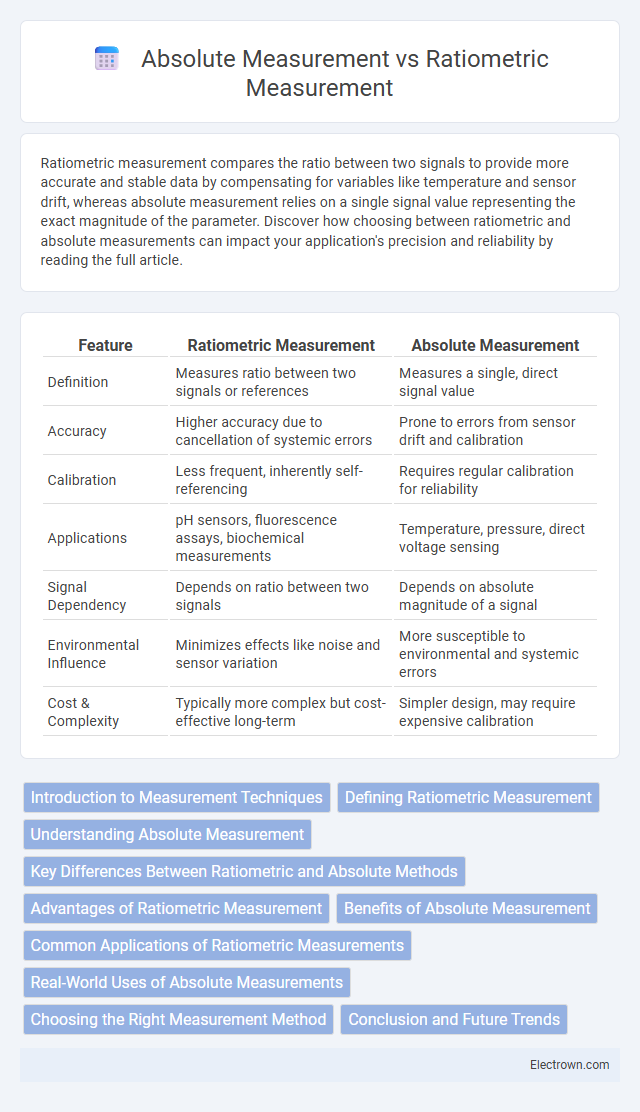

| Feature | Ratiometric Measurement | Absolute Measurement |

|---|---|---|

| Definition | Measures ratio between two signals or references | Measures a single, direct signal value |

| Accuracy | Higher accuracy due to cancellation of systemic errors | Prone to errors from sensor drift and calibration |

| Calibration | Less frequent, inherently self-referencing | Requires regular calibration for reliability |

| Applications | pH sensors, fluorescence assays, biochemical measurements | Temperature, pressure, direct voltage sensing |

| Signal Dependency | Depends on ratio between two signals | Depends on absolute magnitude of a signal |

| Environmental Influence | Minimizes effects like noise and sensor variation | More susceptible to environmental and systemic errors |

| Cost & Complexity | Typically more complex but cost-effective long-term | Simpler design, may require expensive calibration |

Introduction to Measurement Techniques

Ratiometric measurement compares the ratio of two related signals, enhancing accuracy by minimizing the effects of signal drift, sensor variability, and external noise. Absolute measurement determines a parameter directly against a fixed reference, providing straightforward data but often requiring precise calibration and environmental control. Understanding these techniques is crucial for selecting the optimal method based on your application's accuracy, stability, and complexity requirements.

Defining Ratiometric Measurement

Ratiometric measurement quantifies a target parameter by comparing two related signals, creating a ratio that compensates for external variations such as sensor drift or environmental changes. This method improves accuracy and reliability by normalizing fluctuations, unlike absolute measurement, which relies on a single direct reading that may be affected by systemic errors. Ratiometric techniques are widely used in fields like fluorescence sensing, pH measurement, and ion concentration analysis for enhanced precision.

Understanding Absolute Measurement

Absolute measurement provides precise quantification by comparing a sensor's output directly to a fixed reference or known standard, ensuring accurate, consistent data across different conditions. This method eliminates variability caused by sensor drift, temperature fluctuations, or power supply changes, making it ideal for applications requiring high accuracy and repeatability. Devices like thermocouples and strain gauges often utilize absolute measurement to deliver reliable, real-world value readings critical for industrial and scientific processes.

Key Differences Between Ratiometric and Absolute Methods

Ratiometric measurement compares the ratio of two signals, minimizing the impact of external factors like source intensity or detector sensitivity, while absolute measurement quantifies a single parameter based on a fixed reference. Ratiometric methods provide more reliable data in fluctuating conditions due to their internal normalization, whereas absolute techniques require precise calibration and stable setup to ensure accuracy. Your choice between these methods depends on the need for robustness against environmental variations or the requirement for direct, standalone quantification.

Advantages of Ratiometric Measurement

Ratiometric measurement offers enhanced accuracy by compensating for fluctuations in sensor output, environmental changes, and power supply variations, ensuring more reliable data compared to absolute measurement. This technique reduces the impact of noise and drift, enabling consistent and repeatable readings in various applications such as pH sensors, strain gauges, and temperature probes. Your system benefits from improved stability and reduced calibration frequency, making ratiometric measurement ideal for precision-critical tasks.

Benefits of Absolute Measurement

Absolute measurement provides direct and quantifiable data without requiring reference points, ensuring higher accuracy and reliability in diverse applications such as temperature sensing and chemical analysis. This approach reduces potential errors associated with calibration drift or reference instability, leading to consistent performance over time. Devices using absolute measurement offer straightforward implementation and interpretation, making them ideal for critical monitoring systems where precise, standalone values are essential.

Common Applications of Ratiometric Measurements

Ratiometric measurements are widely used in sensor applications such as pH sensors, oxygen sensors, and fluorescence-based assays due to their ability to minimize the effects of environmental variability and sensor drift. This technique enhances accuracy in biochemical and medical diagnostics by providing relative signal ratios, which improve reproducibility in varying conditions. Common applications also include temperature compensation in strain gauges and ion-selective electrodes, where precise and stable readings are critical.

Real-World Uses of Absolute Measurements

Absolute measurements provide precise quantification essential in fields such as environmental monitoring, where exact pollutant concentrations determine compliance with safety standards. In healthcare, absolute measurements enable accurate dosing and diagnostics by quantifying biomarker levels without relying on reference ratios. Industrial processes utilize absolute measurements to maintain quality control by directly measuring parameters like temperature, pressure, or chemical composition for consistency and safety.

Choosing the Right Measurement Method

Choosing the right measurement method depends on the application accuracy and environmental stability requirements. Ratiometric measurement offers improved noise immunity and compensates for sensor or supply voltage variations, making it ideal for dynamic conditions. Absolute measurement provides direct readings without referencing changes but may be affected by signal drift and calibration errors, so your choice should align with precision needs and operational context.

Conclusion and Future Trends

Ratiometric measurement offers enhanced accuracy and noise immunity compared to absolute measurement by relying on signal ratios rather than single-point data, reducing the impact of sensor drift and environmental variations. Future trends emphasize integrating advanced machine learning algorithms and sensor fusion techniques to further improve reliability and real-time diagnostics in diverse applications such as biomedical devices and environmental monitoring. Emerging nanomaterials and microelectronics advancements are expected to drive the miniaturization and precision of ratiometric sensors, enabling broader deployment in IoT and wearable technologies.

ratiometric measurement vs absolute measurement Infographic

electrown.com

electrown.com