Contactless tachometers measure rotational speed using laser or infrared sensors, providing accurate readings without physical contact, which reduces wear and maintenance. Understanding the key differences between contactless and mechanical tachometers will help you choose the best option for your specific application--read on to explore their advantages and use cases.

Table of Comparison

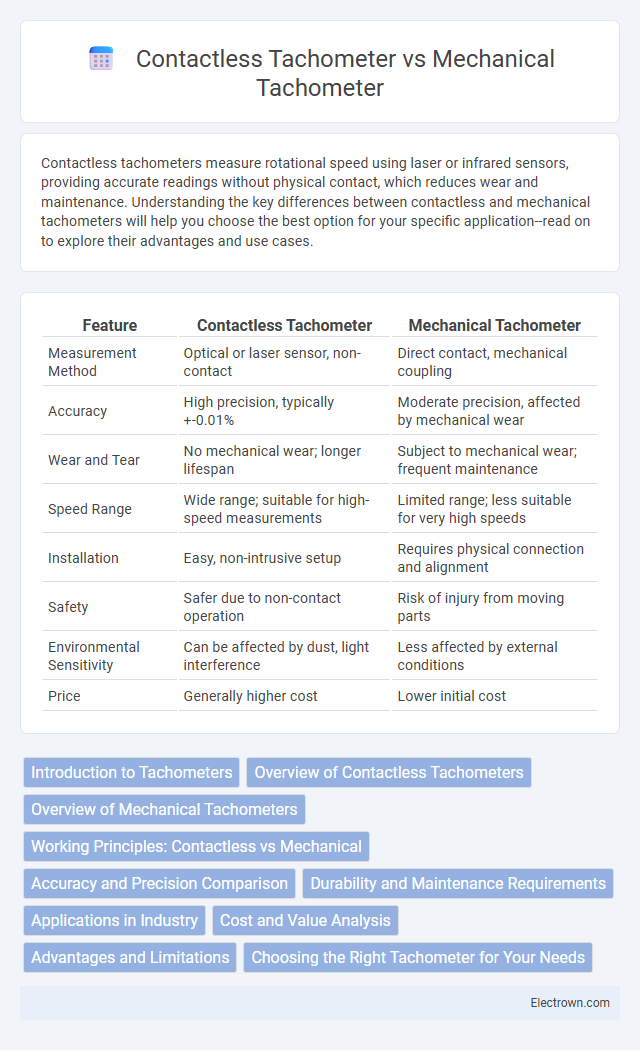

| Feature | Contactless Tachometer | Mechanical Tachometer |

|---|---|---|

| Measurement Method | Optical or laser sensor, non-contact | Direct contact, mechanical coupling |

| Accuracy | High precision, typically +-0.01% | Moderate precision, affected by mechanical wear |

| Wear and Tear | No mechanical wear; longer lifespan | Subject to mechanical wear; frequent maintenance |

| Speed Range | Wide range; suitable for high-speed measurements | Limited range; less suitable for very high speeds |

| Installation | Easy, non-intrusive setup | Requires physical connection and alignment |

| Safety | Safer due to non-contact operation | Risk of injury from moving parts |

| Environmental Sensitivity | Can be affected by dust, light interference | Less affected by external conditions |

| Price | Generally higher cost | Lower initial cost |

Introduction to Tachometers

Contactless tachometers use laser or optical sensors to measure rotational speed without physical contact, offering high precision and minimal wear. Mechanical tachometers rely on direct physical engagement with the rotating part, translating motion into speed readings through mechanical linkage. Contactless models provide faster response times and greater durability compared to traditional mechanical tachometers, enhancing accuracy in various industrial applications.

Overview of Contactless Tachometers

Contactless tachometers use optical or laser sensors to measure rotational speed without physical contact, providing accurate and non-intrusive readings ideal for delicate or high-speed equipment. Unlike mechanical tachometers, which rely on direct physical engagement and moving parts, contactless models eliminate wear and reduce maintenance needs. Your choice of a contactless tachometer enhances safety and precision, especially in environments prone to contamination or where minimal downtime is crucial.

Overview of Mechanical Tachometers

Mechanical tachometers rely on direct physical connection to rotating parts, using gears and shafts to measure rotational speed. These devices convert rotational motion into dial readings typically via a needle, providing real-time RPM data. Mechanical tachometers are known for durability and simplicity but may suffer from wear and reduced accuracy over time due to physical contact.

Working Principles: Contactless vs Mechanical

Contactless tachometers operate by using optical or laser sensors to detect rotational speed without physical contact, emitting a beam that reflects off a marked surface to measure RPM accurately. Mechanical tachometers rely on direct physical connections such as gears or magnetic couplings to translate rotational motion into speed readings, often involving moving parts that can wear over time. The contactless design reduces friction and maintenance needs, providing precise measurements in environments where mechanical tachometers may face durability challenges.

Accuracy and Precision Comparison

Contactless tachometers offer superior accuracy and precision by using laser or optical sensors to measure rotational speed without physical contact, eliminating errors caused by friction or mechanical wear. Mechanical tachometers rely on physical contact, which can introduce inconsistencies due to slip or component degradation over time. When requiring precise RPM measurements for your applications, a contactless tachometer ensures consistent and reliable data collection.

Durability and Maintenance Requirements

Contactless tachometers offer superior durability due to their non-contact measurement method, which eliminates wear and tear on internal components compared to mechanical tachometers. Mechanical tachometers require regular maintenance to address gear wear, lubrication needs, and potential sensor misalignment, increasing downtime and costs. Your choice should consider long-term maintenance efficiency, where contactless models typically provide lower upkeep and enhanced reliability in harsh or high-use environments.

Applications in Industry

Contactless tachometers are widely used in industrial applications requiring non-intrusive speed measurement, such as motors, turbines, and conveyor belts, where high precision and minimal wear are essential. Mechanical tachometers are often employed in environments where direct physical coupling is feasible, providing reliable readings for engines and rotating machinery under rugged conditions. Your choice between these tachometers depends on factors like maintenance needs, measurement accuracy, and the operating environment.

Cost and Value Analysis

Contactless tachometers often have a higher initial cost due to advanced sensor technology but offer long-term value by minimizing maintenance and wear-related expenses compared to mechanical tachometers. Mechanical tachometers tend to be less expensive upfront but incur ongoing costs from physical contact parts prone to wear and calibration needs. Your decision should weigh upfront investment against durability and maintenance savings to optimize cost efficiency over time.

Advantages and Limitations

Contactless tachometers offer advantages such as non-invasive measurement, high accuracy, and the ability to read rotating speeds without direct contact, reducing wear and tear on equipment. Mechanical tachometers provide reliable, direct measurement using physical connections but may suffer from mechanical wear, limited speed range, and require regular maintenance. Your choice depends on application needs, with contactless models favored for high-speed or delicate systems and mechanical types preferred for rugged, simpler setups.

Choosing the Right Tachometer for Your Needs

Contactless tachometers use optical or laser technology to measure rotational speed without physical contact, offering high accuracy and safety for delicate or high-speed applications. Mechanical tachometers rely on direct physical contact, making them durable and suitable for rugged environments but less precise in comparison. Selecting the right tachometer depends on factors such as measurement accuracy, operating conditions, speed range, and maintenance requirements.

contactless tachometer vs mechanical tachometer Infographic

electrown.com

electrown.com