DAQ cards offer high-speed data acquisition and precise signal processing primarily for testing and measurement applications, while PLCs provide robust control and automation in industrial environments with real-time decision-making capabilities. Explore the rest of this article to understand which option aligns best with your specific automation or data acquisition needs.

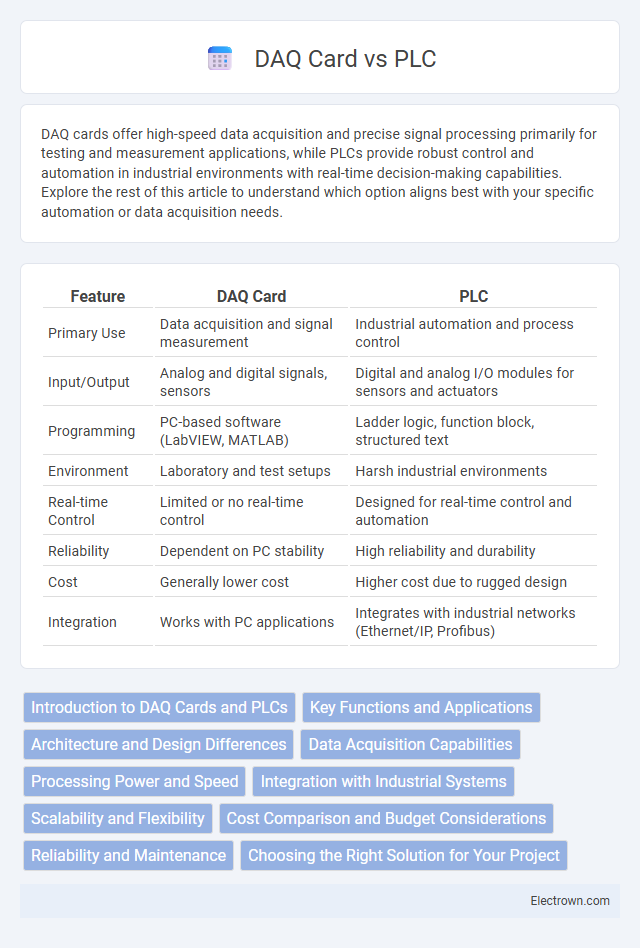

Table of Comparison

| Feature | DAQ Card | PLC |

|---|---|---|

| Primary Use | Data acquisition and signal measurement | Industrial automation and process control |

| Input/Output | Analog and digital signals, sensors | Digital and analog I/O modules for sensors and actuators |

| Programming | PC-based software (LabVIEW, MATLAB) | Ladder logic, function block, structured text |

| Environment | Laboratory and test setups | Harsh industrial environments |

| Real-time Control | Limited or no real-time control | Designed for real-time control and automation |

| Reliability | Dependent on PC stability | High reliability and durability |

| Cost | Generally lower cost | Higher cost due to rugged design |

| Integration | Works with PC applications | Integrates with industrial networks (Ethernet/IP, Profibus) |

Introduction to DAQ Cards and PLCs

DAQ cards, or Data Acquisition Cards, serve as specialized hardware components that capture and process analog and digital signals from various sensors for real-time monitoring and control in experimental and industrial settings. Programmable Logic Controllers (PLCs) are ruggedized industrial computers designed for automation of electromechanical processes, utilizing programmable software to control machinery on factory assembly lines or industrial equipment. Both DAQ cards and PLCs play critical roles in data collection and process automation, with DAQ cards excelling in high-speed, high-resolution signal acquisition and PLCs offering robust control and reliability for complex automation tasks.

Key Functions and Applications

DAQ cards excel in high-speed data acquisition, signal processing, and precise measurement tasks across laboratory and industrial testing environments. PLCs specialize in real-time control, automation of machinery, and process management within manufacturing and production lines. Your choice depends on whether you need advanced data analysis with DAQ or robust, programmable control with PLC systems.

Architecture and Design Differences

DAQ cards feature modular, high-speed analog and digital input/output channels integrated directly with a PC, optimized for precise data acquisition and signal processing in laboratory environments. PLCs utilize a ruggedized, standalone architecture with dedicated processors and real-time control units designed for industrial automation and continuous process control. The DAQ system's architecture emphasizes flexibility and high-resolution measurement, while PLCs prioritize reliability, fault tolerance, and ease of integration into manufacturing control networks.

Data Acquisition Capabilities

DAQ cards excel in high-speed, high-resolution data acquisition ideal for capturing analog and digital signals with precise timing in laboratory environments. PLCs primarily focus on discrete industrial control with robust I/O interfaces but generally offer slower sampling rates and lower resolution compared to DAQ systems. For complex signal processing and real-time data analysis, DAQ cards provide superior capabilities essential in research and testing applications.

Processing Power and Speed

DAQ cards excel in high-speed data acquisition with rapid sampling rates often exceeding 1 MHz, making them ideal for real-time signal processing and precise measurement tasks. PLCs typically operate with lower processing speeds suited for control logic execution, focusing on robustness and reliability rather than raw computational throughput. The microprocessor architecture in DAQ cards supports complex algorithms and fast data throughput, whereas PLC processors prioritize deterministic cycle times and industrial communication protocols.

Integration with Industrial Systems

DAQ cards offer high-speed data acquisition and precise signal processing, making them ideal for real-time monitoring and control within complex industrial systems. PLCs excel in robust automation, seamless communication with various field devices, and reliable execution of control logic across manufacturing processes. Integration with industrial systems is enhanced by PLCs' support for standardized protocols such as Modbus, PROFIBUS, and Ethernet/IP, whereas DAQ cards typically require specialized drivers and middleware for interfacing with industrial networks.

Scalability and Flexibility

DAQ cards offer high scalability and flexibility through modular hardware configurations that can be easily expanded or customized for specific sensor inputs and signal types, making them ideal for varied data acquisition tasks. PLCs provide robust scalability primarily in industrial automation via modular I/O and communication modules, though their flexibility is often limited by proprietary software and fixed control logic structures. For applications requiring extensive customization and diverse sensor integration, DAQ cards generally outperform PLCs in adaptability, while PLCs excel in structured industrial environments with standardized automation processes.

Cost Comparison and Budget Considerations

DAQ cards generally offer a lower initial cost compared to PLCs, making them a budget-friendly option for data acquisition in laboratory or small-scale industrial settings. PLCs, while more expensive upfront, provide robust programmability, scalability, and durability suited for complex and long-term automation projects, justifying their higher investment. Selecting between DAQ cards and PLCs depends on application complexity, total system cost, maintenance expenses, and future expansion plans.

Reliability and Maintenance

DAQ cards offer high reliability with minimal maintenance due to fewer moving parts and robust electronic components designed for precise data acquisition in controlled environments. PLCs, while highly reliable in industrial automation, may require more frequent maintenance because of their exposure to harsh conditions and complex mechanical interfaces. Your choice depends on balancing the low-maintenance advantage of DAQ cards against the rugged durability and service needs of PLCs in demanding environments.

Choosing the Right Solution for Your Project

Choosing between a DAQ card and a PLC hinges on the complexity and scale of your project's data acquisition and control needs. DAQ cards excel in high-speed data sampling and precise signal processing, ideal for laboratory experiments and detailed measurements, while PLCs offer robust, reliable control in industrial automation with better handling of discrete and sequential processes. Your decision should consider factors such as real-time control requirements, environment ruggedness, scalability, and integration capabilities with existing systems.

DAQ card vs PLC Infographic

electrown.com

electrown.com