Reluctance sensors detect changes in magnetic reluctance caused by the presence of a ferromagnetic object, offering simplicity and cost-effectiveness, while Hall effect sensors measure the voltage generated by a magnetic field, providing higher precision and better performance in low-speed applications. Understanding the key differences in operation, accuracy, and suitable use cases will help you choose the right sensor for your needs--read on to explore their advantages and applications.

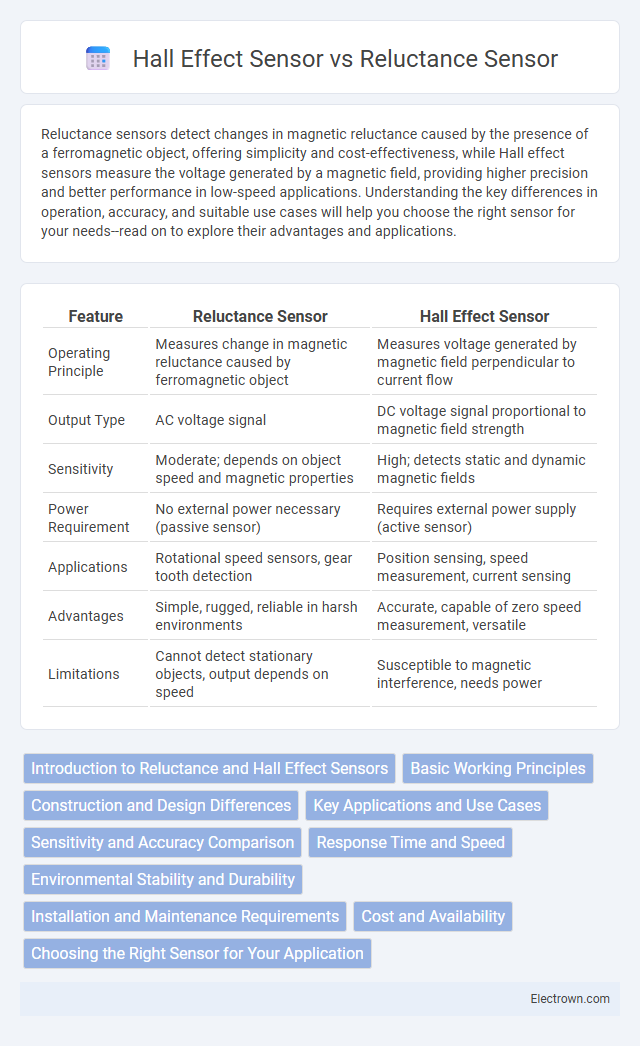

Table of Comparison

| Feature | Reluctance Sensor | Hall Effect Sensor |

|---|---|---|

| Operating Principle | Measures change in magnetic reluctance caused by ferromagnetic object | Measures voltage generated by magnetic field perpendicular to current flow |

| Output Type | AC voltage signal | DC voltage signal proportional to magnetic field strength |

| Sensitivity | Moderate; depends on object speed and magnetic properties | High; detects static and dynamic magnetic fields |

| Power Requirement | No external power necessary (passive sensor) | Requires external power supply (active sensor) |

| Applications | Rotational speed sensors, gear tooth detection | Position sensing, speed measurement, current sensing |

| Advantages | Simple, rugged, reliable in harsh environments | Accurate, capable of zero speed measurement, versatile |

| Limitations | Cannot detect stationary objects, output depends on speed | Susceptible to magnetic interference, needs power |

Introduction to Reluctance and Hall Effect Sensors

Reluctance sensors detect changes in magnetic reluctance caused by the presence or movement of ferromagnetic materials, enabling precise measurement of position, speed, and torque in automotive and industrial applications. Hall Effect sensors rely on the Hall Effect principle, where a magnetic field perpendicular to an electric current generates a voltage, allowing contactless detection of magnetic fields for accurate position and proximity sensing. Both sensor types provide critical data for engine management, anti-lock braking systems, and rotational speed monitoring, with reluctance sensors excelling in durability and Hall Effect sensors offering high sensitivity and linear output.

Basic Working Principles

Reluctance sensors operate by detecting changes in magnetic reluctance when a ferromagnetic object passes through or near a magnetic circuit, causing a variation in inductance that is converted into an electrical signal. Hall effect sensors work by generating a voltage proportional to the magnetic field perpendicular to the current flow in a semiconductor material, allowing precise detection of magnetic flux. Your choice depends on whether you need the indirect inductance-based sensing of reluctance sensors or the direct magnetic field voltage measurement characteristic of Hall effect sensors.

Construction and Design Differences

Reluctance sensors use a ferromagnetic toothed rotor and coils, relying on changes in magnetic reluctance to generate a signal, while Hall effect sensors feature a semiconductor Hall element that produces voltage proportional to the magnetic field. The construction of reluctance sensors includes simple coils and ferromagnetic materials, resulting in a robust and cost-effective design, whereas Hall effect sensors incorporate integrated circuits and magnets, allowing for digital output and higher precision. Design differences lead to reluctance sensors being more suitable for harsh environments due to their durability, while Hall effect sensors excel in applications requiring linear response and variable speed detection.

Key Applications and Use Cases

Reluctance sensors excel in automotive speed sensing and position detection due to their robustness and cost-effectiveness in harsh environments, commonly used in anti-lock braking systems (ABS) and crankshaft position monitoring. Hall effect sensors are widely utilized in brushless DC motors, proximity sensing, and current sensing applications, valued for their high precision and ability to detect magnetic fields without physical contact. Both sensors play critical roles in industrial automation, robotics, and consumer electronics, with reluctance sensors favored for durability and Hall effect sensors preferred for accuracy and versatility.

Sensitivity and Accuracy Comparison

Reluctance sensors typically offer robust sensitivity to changes in magnetic reluctance caused by ferromagnetic objects but may exhibit lower accuracy due to signal noise and temperature variability. Hall effect sensors provide higher accuracy with stable and linear voltage output proportional to magnetic field strength, making them more suitable for precise measurement applications. You should consider Hall effect sensors when sensitivity combined with consistent accuracy is essential for your project.

Response Time and Speed

Reluctance sensors exhibit faster response times than Hall effect sensors due to their direct reliance on changes in magnetic reluctance, enabling rapid detection of rotational speed and position. Hall effect sensors, while accurate in steady-state measurements, tend to have slightly slower response times because they depend on voltage changes created by magnetic fields. Your choice between the two should consider reluctance sensors for high-speed applications requiring quick response, whereas Hall effect sensors suit scenarios needing stable speed detection with less emphasis on response time.

Environmental Stability and Durability

Reluctance sensors exhibit high environmental stability due to their simple construction with no magnets, making them highly resistant to temperature extremes, moisture, and electromagnetic interference. Hall effect sensors, while sensitive and precise, rely on permanent magnets and semiconductor elements that can degrade in harsh environments, potentially affecting long-term durability. Reluctance sensors are often preferred in heavy-duty industrial applications requiring robust performance under severe conditions.

Installation and Maintenance Requirements

Reluctance sensors typically require precise alignment and secure mounting due to their reliance on changes in magnetic reluctance, making installation more sensitive and often necessitating specialized tools or calibration equipment. Hall effect sensors offer easier installation with more tolerance for misalignment, as they detect magnetic fields directly using semiconductor elements, reducing setup complexity and the need for frequent recalibration. Maintenance for reluctance sensors can be more intensive due to mechanical wear or magnet degradation, whereas Hall effect sensors generally require less upkeep, benefiting from solid-state construction and longer operational lifespan.

Cost and Availability

Reluctance sensors generally offer lower cost and higher availability due to simpler design and widespread use in automotive and industrial applications. Hall effect sensors tend to be more expensive but provide greater precision and reliability, leading to moderate availability primarily in specialized electronic components markets. The cost difference is influenced by manufacturing complexity and the use of semiconductor materials in Hall effect sensors versus the passive magnetic components in reluctance sensors.

Choosing the Right Sensor for Your Application

Reluctance sensors operate based on changes in magnetic reluctance caused by a ferromagnetic target passing through the sensor's magnetic field, making them ideal for applications requiring precise rotational speed and position detection without contact. Hall effect sensors measure the Hall voltage generated by a magnetic field perpendicular to the sensor, providing excellent linearity, low power consumption, and versatility in environments with varying magnetic interference. Your choice depends on factors such as desired accuracy, response time, environmental conditions, and cost constraints--reluctance sensors excel in rugged, high-speed scenarios, while Hall sensors better suit applications needing higher sensitivity and signal stability.

Reluctance sensor vs Hall effect sensor Infographic

electrown.com

electrown.com