Four-wire measurement provides higher accuracy by eliminating the effects of lead and contact resistance, making it ideal for precise resistance measurements in low-resistance components. You can explore the detailed differences and applications of both four-wire and two-wire measurement methods in the full article.

Table of Comparison

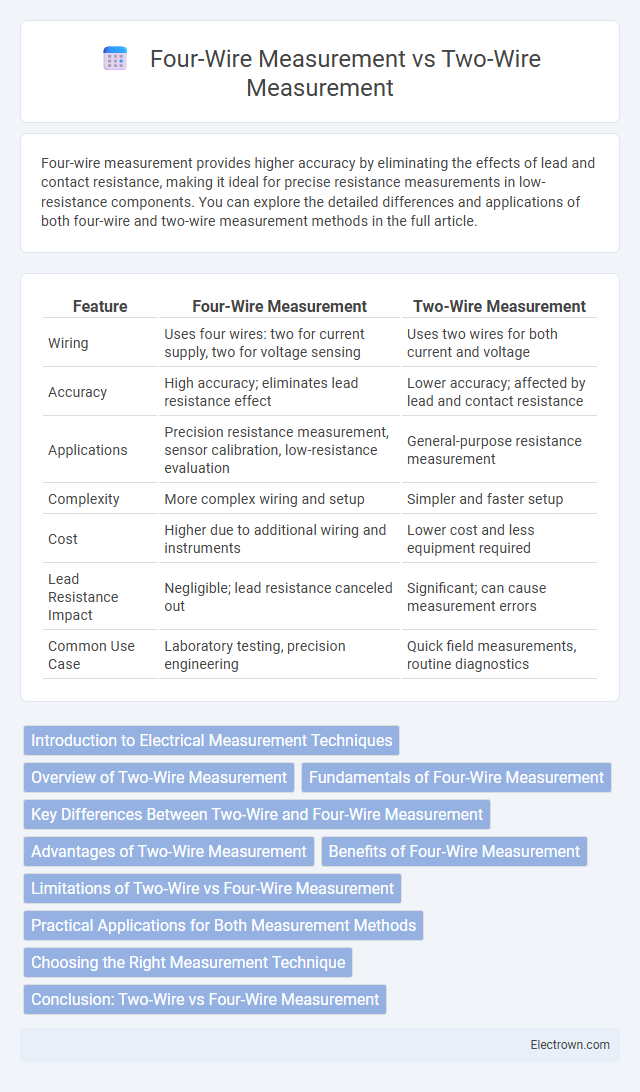

| Feature | Four-Wire Measurement | Two-Wire Measurement |

|---|---|---|

| Wiring | Uses four wires: two for current supply, two for voltage sensing | Uses two wires for both current and voltage |

| Accuracy | High accuracy; eliminates lead resistance effect | Lower accuracy; affected by lead and contact resistance |

| Applications | Precision resistance measurement, sensor calibration, low-resistance evaluation | General-purpose resistance measurement |

| Complexity | More complex wiring and setup | Simpler and faster setup |

| Cost | Higher due to additional wiring and instruments | Lower cost and less equipment required |

| Lead Resistance Impact | Negligible; lead resistance canceled out | Significant; can cause measurement errors |

| Common Use Case | Laboratory testing, precision engineering | Quick field measurements, routine diagnostics |

Introduction to Electrical Measurement Techniques

Four-wire measurement technique significantly improves accuracy by eliminating lead and contact resistance effects common in two-wire systems, making it ideal for precise electrical resistance assessments in low-resistance components. Two-wire measurement connects the meter leads directly to the test element, suitable for general applications but prone to errors due to voltage drops along the leads. In scenarios where precision is critical, your measurements benefit from the four-wire method's separate current and voltage sensing paths, ensuring reliable and accurate electrical readings.

Overview of Two-Wire Measurement

Two-wire measurement connects the sensing and current-carrying leads through the same pair of wires, causing the measured resistance to include both the device under test (DUT) and the lead or contact resistances. This method is simpler and cost-effective but less accurate for low-resistance measurements where lead resistance significantly impacts results. Commonly used in applications where high precision is not critical, two-wire measurement is suitable for general resistance checks and non-sensitive environments.

Fundamentals of Four-Wire Measurement

Four-wire measurement improves accuracy by using separate pairs of wires for current supply and voltage sensing, eliminating the impact of lead and contact resistances on voltage readings. In this technique, the current-carrying wires deliver a known current through the device under test, while the voltage-sensing wires measure the potential difference directly at the terminals, ensuring precise resistance values. Your electrical measurements benefit from reduced errors in low-resistance components, making four-wire configurations essential for precision instrumentation.

Key Differences Between Two-Wire and Four-Wire Measurement

Two-wire measurement uses the same pair of wires for current supply and voltage measurement, often leading to inaccuracies due to lead resistance. Four-wire measurement separates the current-carrying wires from the voltage-sensing wires, eliminating errors caused by lead resistance and improving measurement precision. Your choice between these methods depends on the required accuracy and application sensitivity.

Advantages of Two-Wire Measurement

Two-wire measurement offers simplicity and cost-effectiveness by requiring fewer cables and connections, which reduces installation time and material expenses. This method is suitable for low-accuracy applications where the resistance of test leads has minimal impact on measurement results. Additionally, two-wire measurement is compatible with most basic multimeters and is ideal for quick, routine checks in environments with stable temperature conditions.

Benefits of Four-Wire Measurement

Four-wire measurement significantly improves accuracy by eliminating the effect of lead and contact resistance, allowing precise voltage readings directly at the test point. This technique is essential in low-resistance measurements where even small resistance in the test leads can cause large errors. Consequently, four-wire measurement ensures more reliable and consistent results in sensitive applications like material characterization and precision sensing.

Limitations of Two-Wire vs Four-Wire Measurement

Two-wire measurement suffers from inaccuracies caused by lead and contact resistance, leading to voltage drops that distort precise readings, especially in low-resistance sensors. Four-wire measurement overcomes these limitations by using separate pairs of current-carrying and voltage-sensing leads, ensuring that voltage drop in the leads does not affect the measurement accuracy. Your measurement system benefits from significantly improved precision and reliability when employing the four-wire method in applications where exact resistance values are critical.

Practical Applications for Both Measurement Methods

Four-wire measurement is ideal for precise resistance measurements in low-resistance components where lead and contact resistances can significantly affect accuracy, making it suitable for applications in circuit board testing and temperature sensors. Two-wire measurement is commonly used for general-purpose testing where high precision is not critical, such as checking resistors or wiring continuity in automotive or household electrical systems. Your choice between these methods depends on the required measurement accuracy and the specific practical context of your testing environment.

Choosing the Right Measurement Technique

Four-wire measurement eliminates lead and contact resistance by using separate pairs of current-carrying and voltage-sensing electrodes, providing higher accuracy for low-resistance measurements compared to two-wire measurement. Two-wire measurement is simpler and cost-effective but is susceptible to errors from lead resistance, making it suitable for higher resistance values where precision is less critical. Selecting the appropriate technique depends on the required accuracy, resistance range, and application environment, with four-wire preferred in precision instrumentation and two-wire suited for general testing.

Conclusion: Two-Wire vs Four-Wire Measurement

Four-wire measurement offers higher accuracy by eliminating lead and contact resistance errors, making it ideal for precise low-resistance measurements. Two-wire measurement is simpler and more cost-effective but less accurate due to resistance introduced by the test leads. For applications demanding high precision, four-wire measurement is the preferred method.

four-wire measurement vs two-wire measurement Infographic

electrown.com

electrown.com