SMD fuses are compact, surface-mounted components used primarily on printed circuit boards for protecting delicate electronic devices, while cartridge fuses are cylindrical, designed for higher current applications and often used in industrial and electrical systems. Discover the key differences and which fuse type suits Your specific needs by reading the rest of the article.

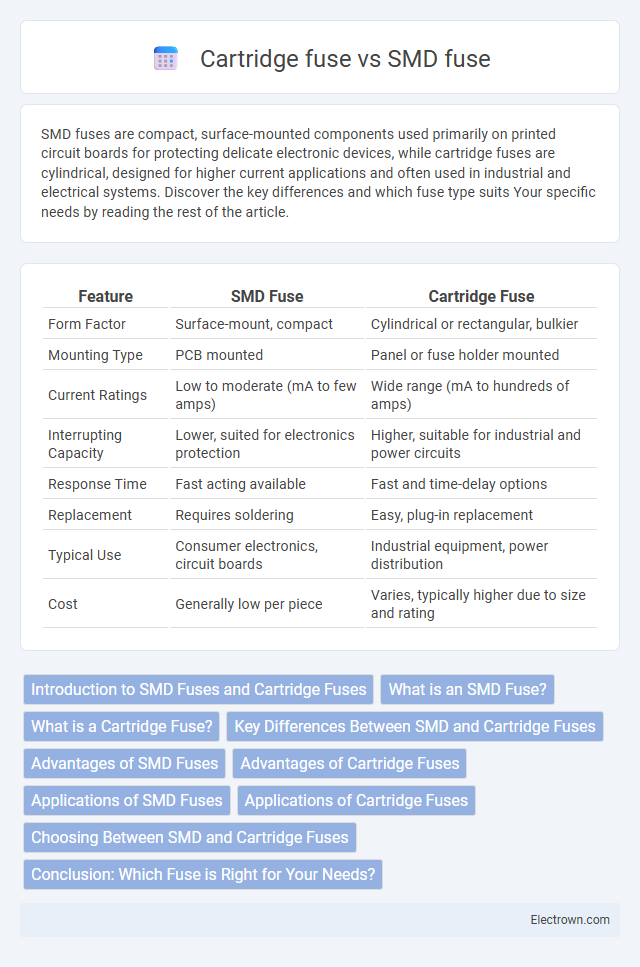

Table of Comparison

| Feature | SMD Fuse | Cartridge Fuse |

|---|---|---|

| Form Factor | Surface-mount, compact | Cylindrical or rectangular, bulkier |

| Mounting Type | PCB mounted | Panel or fuse holder mounted |

| Current Ratings | Low to moderate (mA to few amps) | Wide range (mA to hundreds of amps) |

| Interrupting Capacity | Lower, suited for electronics protection | Higher, suitable for industrial and power circuits |

| Response Time | Fast acting available | Fast and time-delay options |

| Replacement | Requires soldering | Easy, plug-in replacement |

| Typical Use | Consumer electronics, circuit boards | Industrial equipment, power distribution |

| Cost | Generally low per piece | Varies, typically higher due to size and rating |

Introduction to SMD Fuses and Cartridge Fuses

SMD fuses, or Surface Mount Device fuses, are compact, designed for automated PCB assembly, offering fast response and precise circuit protection in small electronic devices. Cartridge fuses are cylindrical, bulkier components suited for higher current applications, providing robust protection by physically interrupting overcurrent flow in industrial and household electrical systems. Your choice between SMD and cartridge fuses depends on circuit size, current rating, and application requirements.

What is an SMD Fuse?

An SMD fuse, or Surface Mount Device fuse, is a compact overcurrent protection component designed for automated PCB assembly, making it ideal for modern electronic devices with limited space. These fuses are mounted directly onto the surface of a printed circuit board (PCB), offering precise current interruption and fast response times, enhancing the reliability of your electronic circuits. Compared to cartridge fuses, SMD fuses provide a lower profile and better integration for high-density applications, ensuring efficient protection without compromising design compactness.

What is a Cartridge Fuse?

A cartridge fuse is a cylindrical electrical safety device designed to protect circuits from overcurrent by breaking the connection when current exceeds a specific threshold. Unlike surface-mount device (SMD) fuses, cartridge fuses consist of a metal wire or strip enclosed in a non-combustible housing, making them suitable for high-current applications and easy replacement. Understanding the characteristics of a cartridge fuse helps you select the appropriate protection for your electronic or electrical systems.

Key Differences Between SMD and Cartridge Fuses

SMD fuses, designed for surface-mount technology, offer compact size and fast response ideal for protecting sensitive electronic circuits, while cartridge fuses are bulkier, cylindrical devices suited for higher current applications with easy replaceability. You'll find SMD fuses integrated directly onto printed circuit boards, enhancing automated assembly, whereas cartridge fuses typically require fuse holders for installation in electrical panels. The key differences include their physical form factor, current and voltage ratings, and mounting methods, influencing selection based on space constraints and fuse replacement needs.

Advantages of SMD Fuses

SMD fuses offer compact size and surface-mount technology compatibility, enabling high-density PCB designs and automated assembly processes. Their fast response time enhances circuit protection and reliability in sensitive electronic devices. You benefit from improved performance and space-saving integration when choosing SMD fuses over cartridge fuses.

Advantages of Cartridge Fuses

Cartridge fuses offer higher current ratings and superior interrupting capacity compared to SMD fuses, making them ideal for industrial and heavy-duty applications. Their robust construction ensures reliable performance under high fault currents and prolonged overload conditions. Easier to replace and compatible with a wide range of fuse holders, cartridge fuses provide enhanced safety and maintenance convenience.

Applications of SMD Fuses

SMD fuses are widely used in compact electronic devices such as smartphones, tablets, and laptops due to their small size and surface-mount compatibility. They provide overcurrent protection in circuit boards for automotive electronics, telecommunications equipment, and medical devices where space constraints and reliability are critical. Their fast response time and ease of automated assembly make them ideal for high-volume manufacturing in consumer electronics and industrial applications.

Applications of Cartridge Fuses

Cartridge fuses are widely used in industrial machinery, automotive systems, and electrical distribution networks due to their high interrupting rating and ability to handle larger currents. These fuses provide reliable protection for motors, transformers, and power supplies by quickly isolating faults and preventing damage. Their robust design allows easy replacement and adaptability in high-power applications where surface-mount device (SMD) fuses may be inadequate.

Choosing Between SMD and Cartridge Fuses

Choosing between SMD fuses and cartridge fuses depends on your application's size constraints and current ratings. SMD fuses offer compact size and fast response times, making them ideal for modern electronics with limited PCB space. Cartridge fuses handle higher currents and offer easy replacement, suitable for industrial or larger electrical systems.

Conclusion: Which Fuse is Right for Your Needs?

SMD fuses offer compact size and fast response times ideal for miniaturized electronic circuits, while cartridge fuses provide higher current ratings and robust protection suitable for industrial or high-power applications. Your choice depends on factors like space constraints, current requirements, and the specific operational environment of your device. Evaluating these elements ensures selecting the fuse that best balances performance, reliability, and safety for your needs.

SMD fuse vs cartridge fuse Infographic

electrown.com

electrown.com