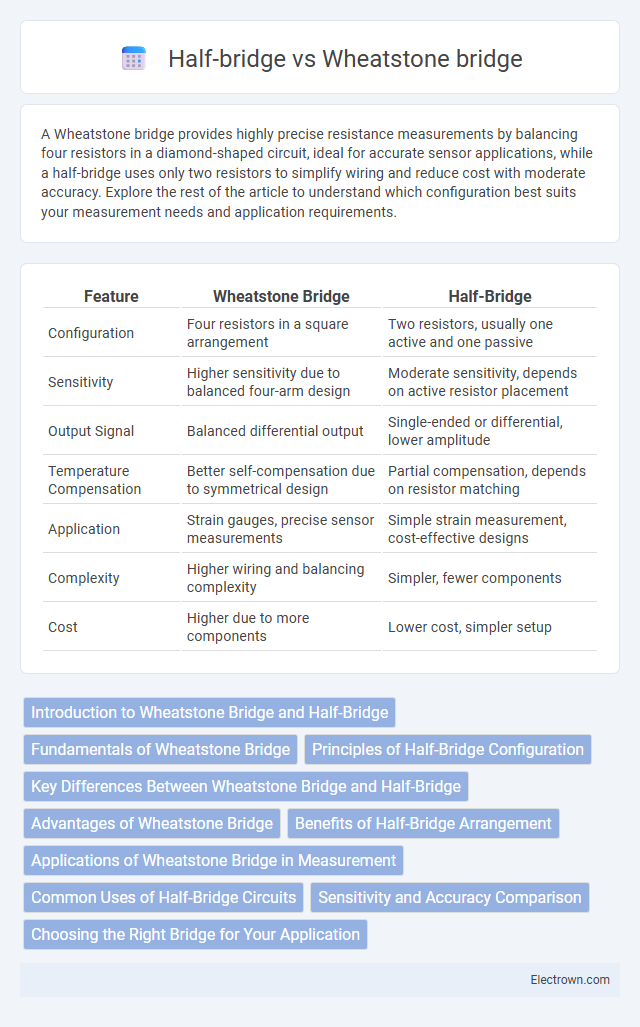

A Wheatstone bridge provides highly precise resistance measurements by balancing four resistors in a diamond-shaped circuit, ideal for accurate sensor applications, while a half-bridge uses only two resistors to simplify wiring and reduce cost with moderate accuracy. Explore the rest of the article to understand which configuration best suits your measurement needs and application requirements.

Table of Comparison

| Feature | Wheatstone Bridge | Half-Bridge |

|---|---|---|

| Configuration | Four resistors in a square arrangement | Two resistors, usually one active and one passive |

| Sensitivity | Higher sensitivity due to balanced four-arm design | Moderate sensitivity, depends on active resistor placement |

| Output Signal | Balanced differential output | Single-ended or differential, lower amplitude |

| Temperature Compensation | Better self-compensation due to symmetrical design | Partial compensation, depends on resistor matching |

| Application | Strain gauges, precise sensor measurements | Simple strain measurement, cost-effective designs |

| Complexity | Higher wiring and balancing complexity | Simpler, fewer components |

| Cost | Higher due to more components | Lower cost, simpler setup |

Introduction to Wheatstone Bridge and Half-Bridge

The Wheatstone bridge is an electrical circuit used to precisely measure unknown resistances by balancing two legs of a bridge circuit, ensuring highly accurate resistance measurements in strain gauge applications. The half-bridge configuration incorporates two active strain gauges, improving sensitivity and temperature compensation compared to a single gauge setup. Both techniques are fundamental in sensor signal conditioning, with the Wheatstone bridge serving as the foundational measurement principle and the half-bridge enhancing performance in dynamic strain measurement environments.

Fundamentals of Wheatstone Bridge

The Wheatstone Bridge operates by balancing two legs of a circuit to precisely measure unknown electrical resistances through voltage differences. Its fundamental design includes four resistors arranged in a diamond shape, with a voltage source applied across the bridge and a galvanometer detecting imbalance. This configuration enables highly accurate resistance measurements, making it essential in strain gauge applications and sensor calibration compared to simpler half-bridge circuits.

Principles of Half-Bridge Configuration

The Half-Bridge configuration in Wheatstone bridge circuits uses two active strain gauges positioned on opposite arms of the bridge to improve sensitivity by detecting differential strain. This setup balances the bridge by having one gauge experience tension while the other undergoes compression, enhancing signal accuracy and temperature compensation. Your choice of a Half-Bridge configuration can significantly increase measurement precision in strain gauge applications compared to a single active gauge in a quarter-bridge.

Key Differences Between Wheatstone Bridge and Half-Bridge

The Wheatstone bridge contains four resistive elements forming a complete bridge, providing high accuracy in measuring unknown resistances by balancing two legs; it is widely used in strain gauge applications for precise strain measurement. The half-bridge configuration incorporates only two active strain gauges, simplifying the circuit and reducing cost, but it offers less sensitivity and temperature compensation compared to the full Wheatstone bridge. Your choice between these depends on the required measurement accuracy, complexity, and environmental conditions affecting the sensor output.

Advantages of Wheatstone Bridge

The Wheatstone bridge offers superior accuracy and sensitivity in measuring electrical resistance compared to a half-bridge configuration, making it ideal for precise sensor applications and strain measurements. Its full-bridge design allows for effective temperature compensation and balanced signal output, which enhances measurement stability and reduces noise interference. You benefit from more reliable data and improved linearity when using a Wheatstone bridge in instrumentation and sensor systems.

Benefits of Half-Bridge Arrangement

The Half-Bridge arrangement offers improved temperature compensation by using two active strain gauges, which enhances measurement stability compared to the Wheatstone bridge's single active gauge setup. It provides greater sensitivity and better noise rejection, making it ideal for applications requiring precise strain or pressure measurements. This configuration reduces errors caused by lead wire resistance, resulting in more accurate and reliable sensor outputs.

Applications of Wheatstone Bridge in Measurement

The Wheatstone bridge is widely used in precision measurement applications such as strain gauge measurements, thermistor resistance detection, and sensor calibration due to its high accuracy in detecting small resistance changes. It enables accurate determination of unknown resistances by balancing two legs of a bridge circuit, making it ideal for laboratory research and industrial instrumentation. In contrast, half-bridge configurations are commonly employed in simplified strain measurement setups where fewer resistive elements need to be monitored.

Common Uses of Half-Bridge Circuits

Half-bridge circuits are commonly used in strain gauge measurements, load cells, and pressure sensors for accurate and temperature-compensated readings. These circuits offer simplified wiring and cost-effectiveness compared to full Wheatstone bridges, making them ideal for compact design applications and partial bridge sensor configurations. Half-bridge configurations effectively balance sensitivity and noise rejection in industrial and biomedical instrumentation.

Sensitivity and Accuracy Comparison

The Wheatstone bridge offers higher sensitivity due to its full-bridge configuration, which allows for better detection of small resistance changes compared to the Half-bridge setup. Accuracy in Wheatstone bridges is generally superior as the full-bridge design effectively compensates for temperature variations and lead wire resistance. The Half-bridge provides moderate sensitivity and accuracy but may require additional calibration to match the precision levels of a Wheatstone bridge in strain measurement applications.

Choosing the Right Bridge for Your Application

Selecting between a Wheatstone bridge and a half-bridge depends on the precision and sensitivity required in your measurement application. The Wheatstone bridge offers superior accuracy for strain gauge measurements by balancing four resistive arms, minimizing temperature effects and noise. Half-bridge configurations provide a cost-effective alternative with moderate sensitivity, suitable for applications where high precision is less critical.

Wheatstone bridge vs Half-bridge Infographic

electrown.com

electrown.com