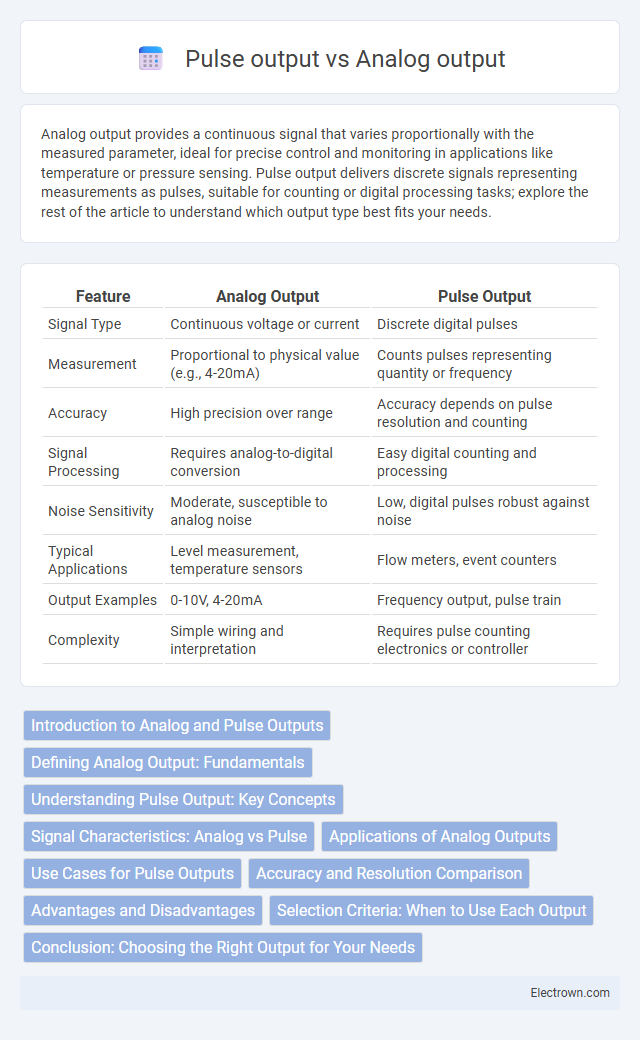

Analog output provides a continuous signal that varies proportionally with the measured parameter, ideal for precise control and monitoring in applications like temperature or pressure sensing. Pulse output delivers discrete signals representing measurements as pulses, suitable for counting or digital processing tasks; explore the rest of the article to understand which output type best fits your needs.

Table of Comparison

| Feature | Analog Output | Pulse Output |

|---|---|---|

| Signal Type | Continuous voltage or current | Discrete digital pulses |

| Measurement | Proportional to physical value (e.g., 4-20mA) | Counts pulses representing quantity or frequency |

| Accuracy | High precision over range | Accuracy depends on pulse resolution and counting |

| Signal Processing | Requires analog-to-digital conversion | Easy digital counting and processing |

| Noise Sensitivity | Moderate, susceptible to analog noise | Low, digital pulses robust against noise |

| Typical Applications | Level measurement, temperature sensors | Flow meters, event counters |

| Output Examples | 0-10V, 4-20mA | Frequency output, pulse train |

| Complexity | Simple wiring and interpretation | Requires pulse counting electronics or controller |

Introduction to Analog and Pulse Outputs

Analog outputs deliver continuous voltage or current signals representing variable parameters, ideal for precise control in industrial automation systems. Pulse outputs emit discrete electrical pulses, commonly used for counting, frequency measurement, and digital signaling in equipment like flow meters and encoders. Understanding the difference between your device's analog and pulse output capabilities ensures accurate data interpretation and system integration.

Defining Analog Output: Fundamentals

Analog output delivers continuous voltage or current signals representing varying physical parameters such as temperature, pressure, or flow rate, enabling real-time and precise control in industrial automation. It typically ranges from 0-10V, 4-20mA, or other standard signal levels, ensuring compatibility with sensors and controllers. This continuous signal variation contrasts with discrete pulse output, which encodes information in frequency or count pulses rather than continuous amplitude changes.

Understanding Pulse Output: Key Concepts

Pulse output converts physical signals into discrete pulses, enabling precise measurement of variables like flow rate or frequency, essential in automation systems. Analog output, on the other hand, delivers continuous voltage or current signals proportional to the measured parameter, suited for smooth control applications. Pulse outputs improve noise immunity and accuracy in digital signal processing, making them ideal for counting and timing functions.

Signal Characteristics: Analog vs Pulse

Analog output signals vary continuously over a range, representing physical quantities such as voltage or current with infinite resolution within the output range, typically 0-10V or 4-20mA. Pulse output signals convey information through discrete pulses, characterized by frequency, duty cycle, or pulse width, making them suited for digital counting or flow measurement applications. Analog signals provide smooth and precise representation ideal for proportional control, whereas pulse outputs excel in noise immunity and digital integration.

Applications of Analog Outputs

Analog outputs are commonly used in industrial automation to provide continuous varying signals to control devices such as valves, actuators, and speed drives, offering precise adjustments for processes. These outputs support applications like temperature control, flow regulation, and pressure monitoring by delivering voltage or current signals proportional to measured parameters. Your systems benefit from smooth, proportional control that pulse outputs may not deliver in applications demanding fine-tuned responses.

Use Cases for Pulse Outputs

Pulse outputs are ideal for applications requiring precise measurement and control of discrete events, such as flow rate monitoring in water treatment plants, counting objects on assembly lines, and generating frequency signals for industrial automation. Their ability to represent digital signals in the form of pulses makes them suitable for systems that interact with controllers, counters, or frequency meters. Industries like manufacturing, utilities, and instrumentation commonly use pulse outputs for tasks involving rapid event detection and data acquisition.

Accuracy and Resolution Comparison

Analog output typically provides continuous voltage or current signals with resolution limited by the digital-to-analog converter (DAC) used, often ranging from 12-bit to 16-bit resolution, which directly impacts accuracy and signal smoothness. Pulse output, commonly represented by pulse width modulation (PWM) or frequency pulses, offers high resolution through digital encoding but may require filtering or decoding for precise analog representation, potentially reducing effective accuracy. In applications demanding fine granularity and stable signal levels, high-resolution analog output is preferred, whereas pulse output excels in digital systems where noise immunity and signal integrity over distances are critical.

Advantages and Disadvantages

Analog output provides smooth, continuous signal representation, enabling precise control and real-time monitoring in applications like industrial automation, but it can be susceptible to noise interference and signal degradation over long distances. Pulse output offers robust, discrete signals ideal for counting, speed measurement, and digital communication, with resistance to electrical noise and simpler signal processing; however, it may lack the resolution and granularity required for fine control. Selecting between analog and pulse outputs depends on application requirements for accuracy, signal stability, and environmental conditions.

Selection Criteria: When to Use Each Output

Analog output is ideal for applications requiring continuous signal variation, such as controlling temperature, speed, or pressure where smooth and precise adjustment is needed. Pulse output suits scenarios involving discrete event counting, positioning, or speed measurement, especially in digital systems that interpret pulses for accurate timing and control. Selection depends on the need for signal granularity, response time, and compatibility with input devices or controllers.

Conclusion: Choosing the Right Output for Your Needs

Analog output provides continuous signal variation ideal for applications requiring precise measurement and control, such as temperature or pressure monitoring. Pulse output delivers discrete signals suitable for counting, speed measurement, and digital communication needs, commonly used in flow meters and encoders. Selecting the right output depends on the specific application requirements, sensor compatibility, and the desired level of signal resolution and complexity.

Analog output vs Pulse output Infographic

electrown.com

electrown.com