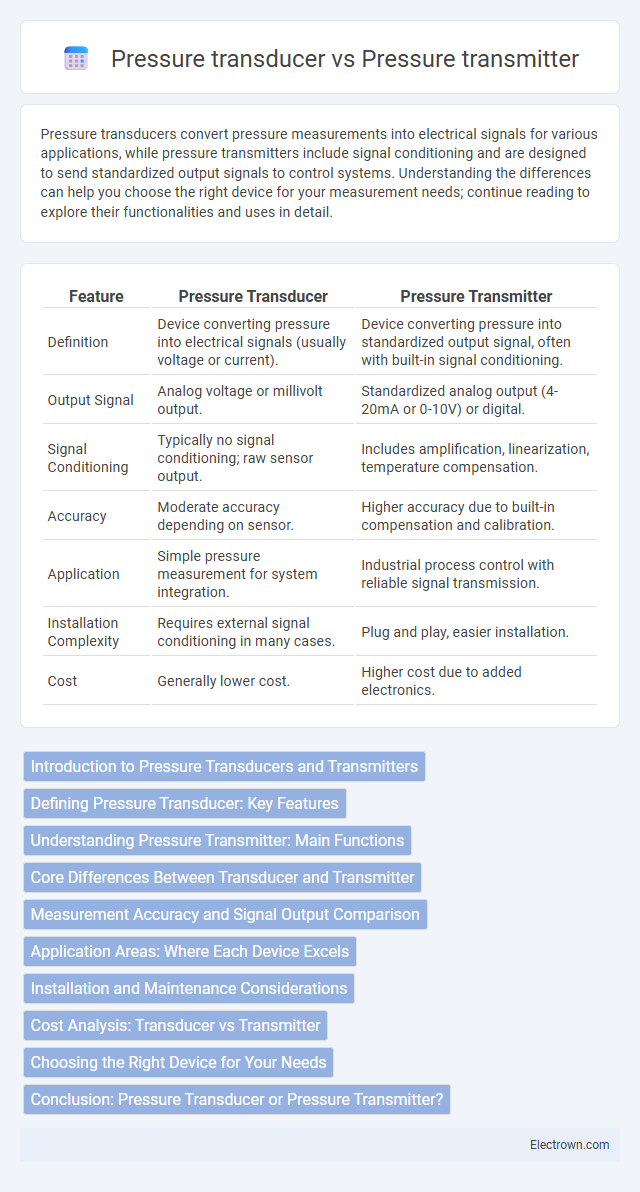

Pressure transducers convert pressure measurements into electrical signals for various applications, while pressure transmitters include signal conditioning and are designed to send standardized output signals to control systems. Understanding the differences can help you choose the right device for your measurement needs; continue reading to explore their functionalities and uses in detail.

Table of Comparison

| Feature | Pressure Transducer | Pressure Transmitter |

|---|---|---|

| Definition | Device converting pressure into electrical signals (usually voltage or current). | Device converting pressure into standardized output signal, often with built-in signal conditioning. |

| Output Signal | Analog voltage or millivolt output. | Standardized analog output (4-20mA or 0-10V) or digital. |

| Signal Conditioning | Typically no signal conditioning; raw sensor output. | Includes amplification, linearization, temperature compensation. |

| Accuracy | Moderate accuracy depending on sensor. | Higher accuracy due to built-in compensation and calibration. |

| Application | Simple pressure measurement for system integration. | Industrial process control with reliable signal transmission. |

| Installation Complexity | Requires external signal conditioning in many cases. | Plug and play, easier installation. |

| Cost | Generally lower cost. | Higher cost due to added electronics. |

Introduction to Pressure Transducers and Transmitters

Pressure transducers convert pressure into an electrical signal, typically voltage or current, suitable for measurement and control applications. Pressure transmitters, on the other hand, not only sense pressure but also amplify and condition the signal to an industry-standard output like 4-20 mA for long-distance transmission. Both devices are essential in industrial automation, offering precise pressure monitoring in processes such as oil refining, HVAC systems, and hydraulic controls.

Defining Pressure Transducer: Key Features

A pressure transducer converts pressure into an electrical signal, offering precise measurement with sensor elements such as strain gauges or piezoelectric sensors. Key features include high sensitivity, compact size, and the ability to deliver raw analog signals for further processing. Your choice depends on whether you need simple signal output or a fully integrated system like a pressure transmitter.

Understanding Pressure Transmitter: Main Functions

Pressure transmitters convert pressure measurements into an electrical signal for precise monitoring and control in industrial processes. They integrate a pressure sensor with signal conditioning, providing reliable output such as 4-20 mA or digital communication protocols. These devices enable real-time data transmission, enhancing automation and safety in applications like oil and gas, HVAC, and manufacturing systems.

Core Differences Between Transducer and Transmitter

Pressure transducers convert physical pressure into an electrical signal, typically voltage or current, which requires further processing for interpretation. Pressure transmitters include an integrated sensor and a signal conditioner, providing amplified, linearized, and standardized output ready for direct input to control systems. Your choice depends on the level of signal processing and environment compatibility needed for accurate pressure measurement.

Measurement Accuracy and Signal Output Comparison

Pressure transducers typically provide raw electrical signals such as millivolts or ohms, requiring external signal conditioning for accurate interpretation, whereas pressure transmitters output standardized signals like 4-20 mA or digital protocols, ensuring higher measurement accuracy and easier integration with control systems. The signal conditioning within pressure transmitters enhances sensitivity and reduces noise, resulting in more precise and stable pressure readings compared to transducers. For applications demanding reliable data and minimal signal degradation over long distances, pressure transmitters offer superior performance in both accuracy and signal integrity.

Application Areas: Where Each Device Excels

Pressure transducers excel in applications requiring high-accuracy measurement of dynamic pressures, such as in automotive engine testing, aerospace systems, and process control where compact size and fast response time are crucial. Pressure transmitters are better suited for industrial environments needing robust, long-distance signal transmission and integration into control systems, commonly found in oil and gas pipelines, water treatment plants, and HVAC systems. The choice depends on factors like environmental conditions, communication needs, and measurement precision.

Installation and Maintenance Considerations

Pressure transducers typically require direct mounting at the measurement point, often in areas with limited space, making installation straightforward but sometimes challenging in confined environments. Maintenance involves regular calibration and protection from environmental factors such as temperature extremes or moisture to ensure accuracy over time. Pressure transmitters generally include built-in signal conditioning and are installed with additional wiring to control systems, necessitating careful attention to electrical connections and periodic verification to maintain system integrity.

Cost Analysis: Transducer vs Transmitter

Pressure transducers generally cost less than pressure transmitters due to their simpler design and limited signal conditioning capabilities. Your choice between the two impacts budgeting, as transmitters include built-in amplification and output standardization, which increases initial expenditure but offers more accurate and stable readings for industrial applications. Investing in a pressure transmitter often reduces long-term maintenance costs despite the higher upfront price compared to transducers.

Choosing the Right Device for Your Needs

Selecting between a pressure transducer and a pressure transmitter depends on application requirements such as measurement accuracy, signal output, and environmental conditions. Pressure transducers convert pressure into an electrical signal suitable for local processing, ideal for integration with control systems needing precise analog data. Pressure transmitters enhance this by providing amplified, conditioned standardized output signals like 4-20mA or digital communications, making them preferable for remote monitoring and industrial automation systems.

Conclusion: Pressure Transducer or Pressure Transmitter?

A pressure transducer converts pressure into an electrical signal without processing, while a pressure transmitter includes signal conditioning and often provides a calibrated output suitable for direct integration with control systems. Your choice depends on the application's complexity; use a pressure transducer for basic pressure measurement tasks and a pressure transmitter when accuracy, signal conditioning, and remote monitoring are essential. Understanding these differences ensures optimal performance and reliability in your pressure measurement system.

Pressure transducer vs Pressure transmitter Infographic

electrown.com

electrown.com