S-type load cells offer dual tension and compression measurement capabilities, making them versatile for various weighing applications, while shear beam load cells provide higher accuracy and stability in single-point load measurements ideal for industrial scales. Discover which load cell type best suits your specific weighing needs by exploring the detailed comparison in this article.

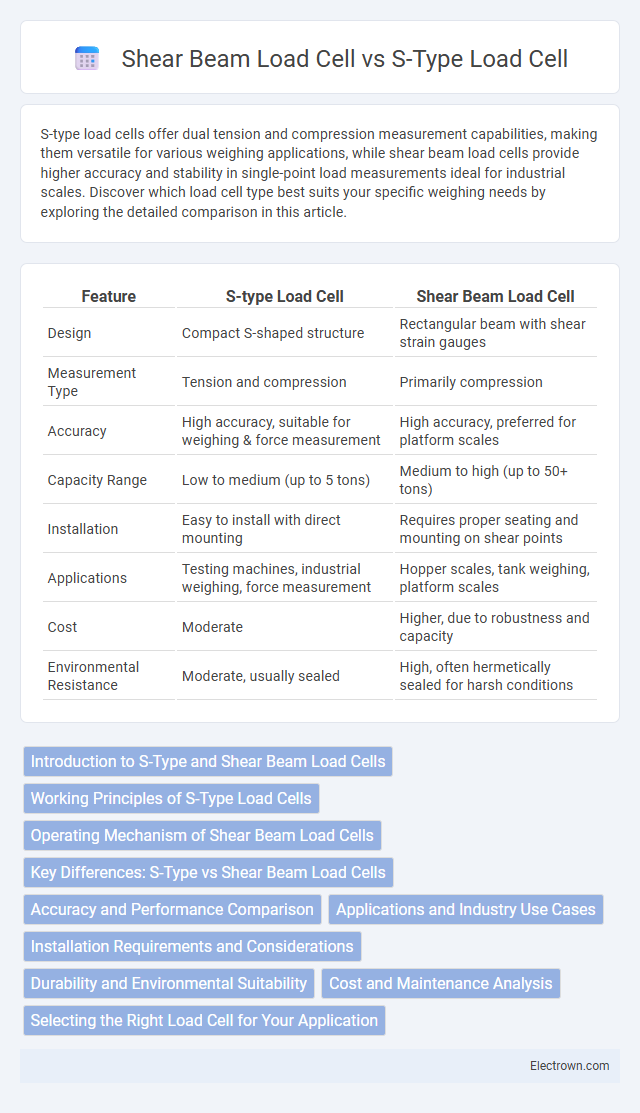

Table of Comparison

| Feature | S-type Load Cell | Shear Beam Load Cell |

|---|---|---|

| Design | Compact S-shaped structure | Rectangular beam with shear strain gauges |

| Measurement Type | Tension and compression | Primarily compression |

| Accuracy | High accuracy, suitable for weighing & force measurement | High accuracy, preferred for platform scales |

| Capacity Range | Low to medium (up to 5 tons) | Medium to high (up to 50+ tons) |

| Installation | Easy to install with direct mounting | Requires proper seating and mounting on shear points |

| Applications | Testing machines, industrial weighing, force measurement | Hopper scales, tank weighing, platform scales |

| Cost | Moderate | Higher, due to robustness and capacity |

| Environmental Resistance | Moderate, usually sealed | High, often hermetically sealed for harsh conditions |

Introduction to S-Type and Shear Beam Load Cells

S-type load cells feature a compact design with a central beam shaped like an "S," allowing them to measure tension and compression forces with high accuracy in scales and testing machines. Shear beam load cells use a robust rectangular or cylindrical design that measures shear forces, making them ideal for heavy industrial applications such as hopper weighing and tank weighing. Both types utilize strain gauges to convert mechanical strain into electrical signals, but their structural configurations suit different load measurement requirements and environments.

Working Principles of S-Type Load Cells

S-type load cells operate based on the principle of strain gauge technology, where applied force causes deformation in the load cell body, producing a change in electrical resistance. These cells are designed in a compact, S-shaped structure that enables them to measure tension and compression forces accurately. Their sensitivity and low hysteresis make them ideal for applications requiring precise load measurement.

Operating Mechanism of Shear Beam Load Cells

Shear beam load cells operate by measuring the shear force generated within the beam when a load is applied, transforming mechanical stress into an electrical signal via strain gauges bonded to the beam's surface. Unlike S-type load cells that respond to tension and compression, shear beam load cells detect shear strain specifically, making them ideal for platform scales and industrial weighing applications with high accuracy and stability. Your choice of a shear beam load cell ensures reliable measurement under harsh and dynamic conditions due to its robust construction and resistance to off-center loading effects.

Key Differences: S-Type vs Shear Beam Load Cells

S-type load cells offer high accuracy and dual tension-compression measurement, making them ideal for applications requiring precise weight monitoring and force measurement, while shear beam load cells provide robust performance and durability in heavy-duty industrial weighing systems. The main differences lie in their structural design; S-type load cells have a compact, S-shaped design enabling easy integration into tight spaces, whereas shear beam load cells feature a rectangular beam designed to handle high-capacity loads with minimal deflection. Your choice depends on the measurement environment and accuracy requirements, with S-type excelling in precision tasks and shear beam suited for rugged, high-capacity settings.

Accuracy and Performance Comparison

S-type load cells typically offer higher accuracy with minimal hysteresis and excellent repeatability, making them ideal for precision weighing applications. Shear beam load cells provide robust performance under high-capacity loads and are widely used in industrial settings due to their durability and resistance to off-center loading errors. Your choice depends on whether you prioritize precise measurement or heavy-duty performance in the specific application environment.

Applications and Industry Use Cases

S-type load cells excel in tension and compression measurement applications, making them ideal for weighing systems in packaging, hopper weighing, and material testing industries. Shear beam load cells are widely used in heavy-duty industrial environments such as truck scales, tank weighing, and conveyor systems due to their high accuracy and rigidity. Both load cell types serve critical roles in manufacturing, agriculture, and logistics sectors for precise force measurement and process control.

Installation Requirements and Considerations

S-type load cells require precise alignment during installation to ensure accurate tension and compression measurements, typically needing secure mounting with threaded holes or through-bolts. Shear beam load cells demand robust anchoring on a stable surface, often using mounting holes with proper torque specifications to prevent movement and ensure consistent shear force measurement. Proper installation of both load cell types is crucial to maintain accuracy, with your setup considerations focusing on minimizing external forces and vibrations.

Durability and Environmental Suitability

S-type load cells offer moderate durability and perform well in controlled environments with low exposure to moisture and contaminants. Shear beam load cells provide higher durability and are designed for harsh industrial conditions, exhibiting superior resistance to dust, moisture, and mechanical stress. Their robust construction makes shear beam load cells more suitable for outdoor or heavy-duty applications requiring consistent long-term reliability.

Cost and Maintenance Analysis

S-type load cells typically offer a lower upfront cost compared to shear beam load cells, making them a cost-effective choice for applications requiring moderate capacity and precision. Maintenance for S-type load cells is generally minimal due to their compact design, but they might be less durable under heavy industrial conditions. Shear beam load cells, while more expensive initially, provide enhanced robustness and longevity in harsh environments, reducing long-term maintenance expenses despite higher upfront investment.

Selecting the Right Load Cell for Your Application

S-type load cells excel in tension and compression applications requiring high accuracy and compact design, making them ideal for platform scales and material testing. Shear beam load cells offer superior performance in heavy-duty weighing systems, such as truck scales and batching systems, due to their robust construction and excellent resistance to off-center loads. Selecting the right load cell depends on factors like load capacity, environment, mounting configuration, and measurement precision needed for your specific industrial application.

S-type load cell vs Shear beam load cell Infographic

electrown.com

electrown.com