Embedded systems are specialized computing devices designed to perform dedicated functions within larger mechanical or electrical systems, while Programmable Logic Controllers (PLCs) are ruggedized digital computers used for automation of industrial processes, offering real-time control and reliability in harsh environments. Understanding the differences in application, programming complexity, and adaptability will help You choose the right solution for your automation needs--explore the rest of the article to learn more.

Table of Comparison

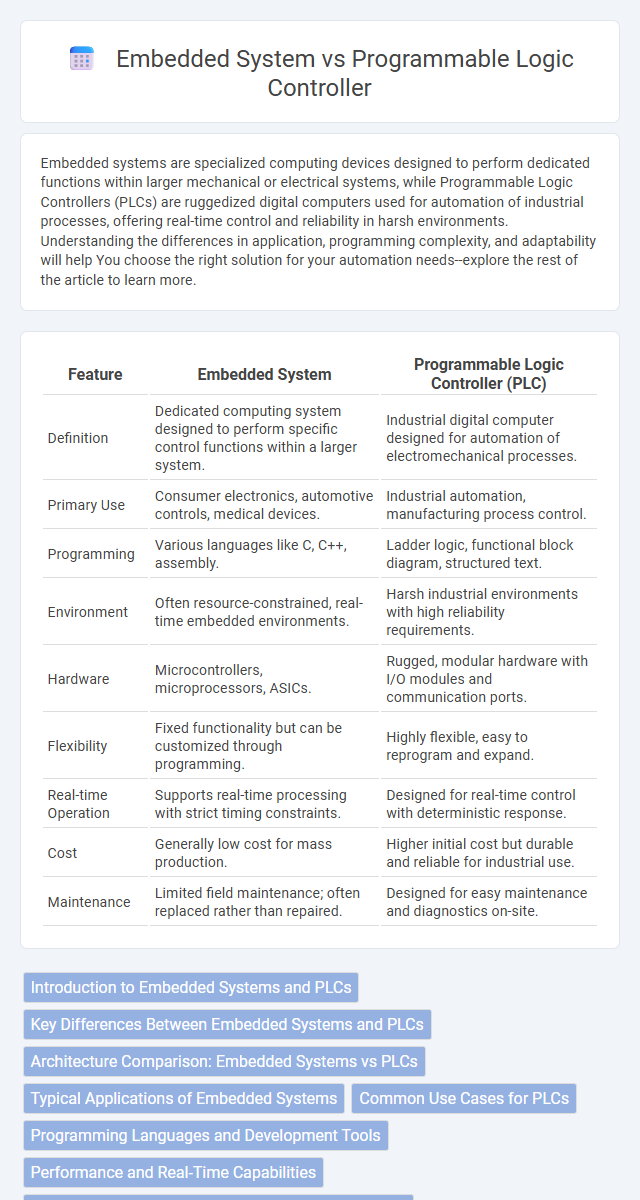

| Feature | Embedded System | Programmable Logic Controller (PLC) |

|---|---|---|

| Definition | Dedicated computing system designed to perform specific control functions within a larger system. | Industrial digital computer designed for automation of electromechanical processes. |

| Primary Use | Consumer electronics, automotive controls, medical devices. | Industrial automation, manufacturing process control. |

| Programming | Various languages like C, C++, assembly. | Ladder logic, functional block diagram, structured text. |

| Environment | Often resource-constrained, real-time embedded environments. | Harsh industrial environments with high reliability requirements. |

| Hardware | Microcontrollers, microprocessors, ASICs. | Rugged, modular hardware with I/O modules and communication ports. |

| Flexibility | Fixed functionality but can be customized through programming. | Highly flexible, easy to reprogram and expand. |

| Real-time Operation | Supports real-time processing with strict timing constraints. | Designed for real-time control with deterministic response. |

| Cost | Generally low cost for mass production. | Higher initial cost but durable and reliable for industrial use. |

| Maintenance | Limited field maintenance; often replaced rather than repaired. | Designed for easy maintenance and diagnostics on-site. |

Introduction to Embedded Systems and PLCs

Embedded systems are specialized computing systems designed to perform dedicated functions within larger mechanical or electrical systems, often featuring microcontrollers or microprocessors tailored for real-time applications. Programmable Logic Controllers (PLCs) are robust industrial digital computers optimized for controlling manufacturing processes, machinery, and automation systems with high reliability and ease of programming. Understanding the differences helps you select the right control solution for automation tasks, balancing flexibility and application-specific requirements.

Key Differences Between Embedded Systems and PLCs

Embedded systems integrate dedicated hardware and software tailored for specific control functions within devices, emphasizing compactness and real-time operation. Programmable Logic Controllers (PLCs) offer rugged, industrial-grade automation with modular input/output configurations and user-friendly programming for machine control and process automation. Key differences include the embedded system's customizability and diverse applications versus the PLC's standardized design for high-reliability environments and ease of maintenance.

Architecture Comparison: Embedded Systems vs PLCs

Embedded systems feature a microcontroller or microprocessor integrated with memory and I/O ports on a single board, optimized for specific tasks with real-time operating systems or bare-metal software. Programmable Logic Controllers (PLCs) consist of a modular structure with a central processing unit (CPU), input/output modules, communication interfaces, and are designed for robust industrial control with deterministic execution and easy programmability. While embedded systems prioritize customization and compactness, PLC architectures emphasize reliability, scalability, and ruggedness for automated manufacturing processes.

Typical Applications of Embedded Systems

Embedded systems are commonly used in consumer electronics such as smartphones, wearable devices, and home automation systems, where real-time processing and low power consumption are essential. Industrial automation employs embedded systems for sensor data acquisition, motor control, and communication protocols within manufacturing equipment. Automotive applications include engine control units (ECUs), infotainment systems, and advanced driver-assistance systems (ADAS) relying on embedded computing for safety and performance optimization.

Common Use Cases for PLCs

Programmable Logic Controllers (PLCs) are widely used in industrial automation, controlling machinery on factory assembly lines, and managing processes in manufacturing plants. Embedded systems, while versatile, are typically integrated into specific devices such as home appliances or automotive controls, whereas PLCs excel in real-time monitoring and controlling complex industrial operations due to their rugged design and ease of programming. Your industrial automation projects benefit from PLCs' robust reliability, modularity, and ability to interface with various sensors and actuators in environments demanding high uptime and precision.

Programming Languages and Development Tools

Embedded systems commonly utilize programming languages such as C, C++, and assembly, with development tools including integrated development environments (IDEs) like Keil, IAR, and MPLAB for efficient hardware-level control and optimization. Programmable Logic Controllers (PLCs) primarily rely on IEC 61131-3 standard languages like Ladder Logic, Structured Text, and Function Block Diagram, using specialized software such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider Unity Pro for industrial automation tasks. Your choice depends on application complexity, real-time requirements, and preferred development environments tailored to hardware interaction and automation needs.

Performance and Real-Time Capabilities

Embedded systems offer high performance with customizable hardware and software integration, enabling precise control and efficient processing tailored to specific applications. Programmable Logic Controllers (PLCs) excel in real-time capabilities due to their deterministic operation and robust design, ensuring reliable and timely responses in industrial automation environments. You benefit from selecting an embedded system when flexibility and high-speed data handling are essential, while PLCs provide superior predictability and stability for critical real-time control tasks.

Reliability and Robustness in Industrial Environments

Embedded systems offer tailored reliability for specific industrial tasks with optimized hardware-software integration, while Programmable Logic Controllers (PLCs) provide exceptional robustness through standardized, rugged designs certified for harsh environments like extreme temperatures, vibrations, and electrical noise. PLCs' modular architecture ensures quick fault detection and high uptime, essential for mission-critical industrial automation, whereas embedded systems can be customized for specialized applications but may require additional protection to match PLCs' durability. Your choice depends on the required balance between customization flexibility and the proven industrial-grade resilience PLCs inherently deliver.

Cost Considerations and Scalability

Embedded systems typically offer lower initial costs due to their tailored hardware and software integration, making them ideal for cost-sensitive applications. Programmable Logic Controllers (PLCs) have higher upfront expenses but provide superior scalability and modularity, enabling easy expansion and long-term adaptability in industrial environments. Your choice depends on balancing budget constraints with future scalability requirements.

Choosing the Right Solution for Your Automation Needs

Embedded systems offer customized control with high flexibility and integration for specific automation tasks, while programmable logic controllers (PLCs) provide robust reliability and ease of programming for industrial environments. Your choice depends on factors like system complexity, scalability, environmental conditions, and maintenance requirements, where embedded systems suit specialized, compact applications and PLCs excel in standardized, heavy-duty operations. Careful evaluation of your automation needs ensures the right balance between performance, cost, and adaptability for optimal system functionality.

Embedded system vs Programmable logic controller Infographic

electrown.com

electrown.com