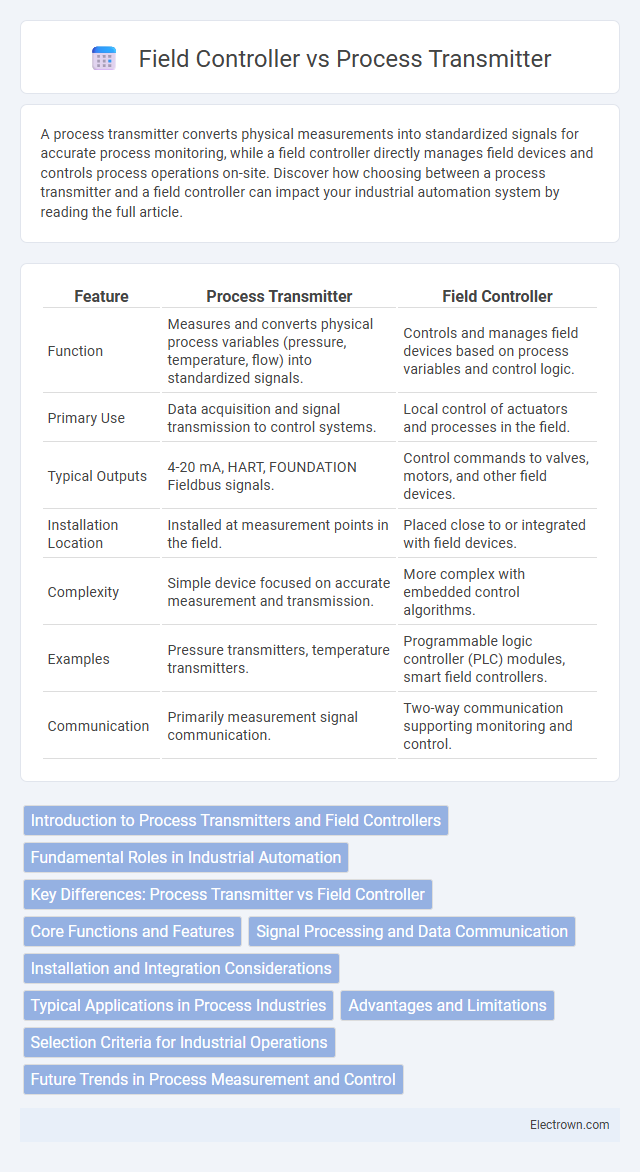

A process transmitter converts physical measurements into standardized signals for accurate process monitoring, while a field controller directly manages field devices and controls process operations on-site. Discover how choosing between a process transmitter and a field controller can impact your industrial automation system by reading the full article.

Table of Comparison

| Feature | Process Transmitter | Field Controller |

|---|---|---|

| Function | Measures and converts physical process variables (pressure, temperature, flow) into standardized signals. | Controls and manages field devices based on process variables and control logic. |

| Primary Use | Data acquisition and signal transmission to control systems. | Local control of actuators and processes in the field. |

| Typical Outputs | 4-20 mA, HART, FOUNDATION Fieldbus signals. | Control commands to valves, motors, and other field devices. |

| Installation Location | Installed at measurement points in the field. | Placed close to or integrated with field devices. |

| Complexity | Simple device focused on accurate measurement and transmission. | More complex with embedded control algorithms. |

| Examples | Pressure transmitters, temperature transmitters. | Programmable logic controller (PLC) modules, smart field controllers. |

| Communication | Primarily measurement signal communication. | Two-way communication supporting monitoring and control. |

Introduction to Process Transmitters and Field Controllers

Process transmitters convert physical process variables such as pressure, temperature, or flow into standardized electrical signals for monitoring and control, ensuring accurate data transmission within industrial automation systems. Field controllers manage these process variables locally by processing input from transmitters and executing control actions to maintain optimal process conditions. Your selection between process transmitters and field controllers depends on the specific control architecture, with transmitters primarily focusing on measurement accuracy and field controllers on real-time process control.

Fundamental Roles in Industrial Automation

Process transmitters convert physical measurements such as pressure, temperature, or flow into standardized electrical signals for accurate data transmission in industrial automation systems. Field controllers receive these signals, execute control algorithms, and send commands to actuators to maintain process variables within desired parameters. Understanding the distinction between your process transmitter and field controller is essential for optimizing system performance and ensuring precise process control.

Key Differences: Process Transmitter vs Field Controller

Process transmitters convert physical measurements such as pressure, temperature, or flow into standardized electrical signals for control systems, ensuring accurate data communication. Field controllers directly process input signals at the field level, executing control algorithms and sending commands to final control elements without relying on centralized control units. The primary difference lies in functionality: transmitters focus on measurement and signal transmission, while field controllers perform control actions and decision-making locally.

Core Functions and Features

Process transmitters convert physical measurements such as pressure, temperature, or flow from sensors into standardized signals for monitoring and control, emphasizing accuracy and signal conditioning. Field controllers execute control algorithms locally, managing processes by directly adjusting field devices based on input signals to maintain desired setpoints and enhance system responsiveness. Both devices feature robust construction for industrial environments, but transmitters focus on data acquisition while field controllers prioritize immediate control actions.

Signal Processing and Data Communication

Process transmitters convert physical measurements into standardized electrical signals such as 4-20 mA or HART, enabling reliable data communication over long distances with minimal signal degradation. Field controllers process these signals locally, executing control algorithms and communicating with higher-level systems using protocols like Modbus, Profibus, or Ethernet/IP for real-time data exchange. Your choice impacts signal accuracy and communication efficiency, with process transmitters excelling in precise signal conditioning and field controllers enabling advanced local data processing and network integration.

Installation and Integration Considerations

Process transmitters typically offer straightforward installation with direct connection to field instruments, simplifying signal transmission and reducing wiring complexity. Field controllers require more complex integration efforts, as they involve local processing capabilities and often necessitate configuration to interact seamlessly with various field devices and control systems. Your choice will impact the overall setup time, system scalability, and maintenance workflow depending on the level of automation and control precision needed.

Typical Applications in Process Industries

Process transmitters are commonly used to measure variables such as pressure, temperature, and flow in industries like oil and gas, chemical manufacturing, and water treatment, providing accurate data for monitoring and control. Field controllers typically manage complex control loops or local automation tasks in industries such as power generation, pharmaceuticals, and pulp and paper, enabling real-time decision-making at the site level. Your choice depends on whether precise measurement or localized process control is the primary requirement.

Advantages and Limitations

Process transmitters offer advantages such as high accuracy in measuring process variables and easy integration with control systems, enhancing real-time monitoring and data transmission efficiency. Their limitations include susceptibility to signal loss over long distances and potential calibration drift in harsh environments. Field controllers excel in localized decision-making and process control, reducing response time, but they may face constraints in complex system integration and require more maintenance due to exposure to field conditions.

Selection Criteria for Industrial Operations

Selection criteria for industrial operations between process transmitters and field controllers hinge on accuracy, communication protocol compatibility, and environmental conditions. Process transmitters excel in precise measurement of variables like pressure, temperature, and flow, making them ideal for real-time data acquisition. Field controllers offer localized control and logic execution, preferred when immediate decision-making and equipment interfacing are crucial within harsh or distributed industrial environments.

Future Trends in Process Measurement and Control

Future trends in process measurement and control emphasize increased integration of process transmitters and field controllers through advanced IoT connectivity and AI-driven analytics to enable real-time decision-making. Enhanced digital communication protocols like WirelessHART and ISA-100.11a improve data accuracy and reliability, while edge computing allows field controllers to process data locally for faster response times. You can expect these innovations to boost operational efficiency and predictive maintenance in industrial automation.

Process transmitter vs Field controller Infographic

electrown.com

electrown.com