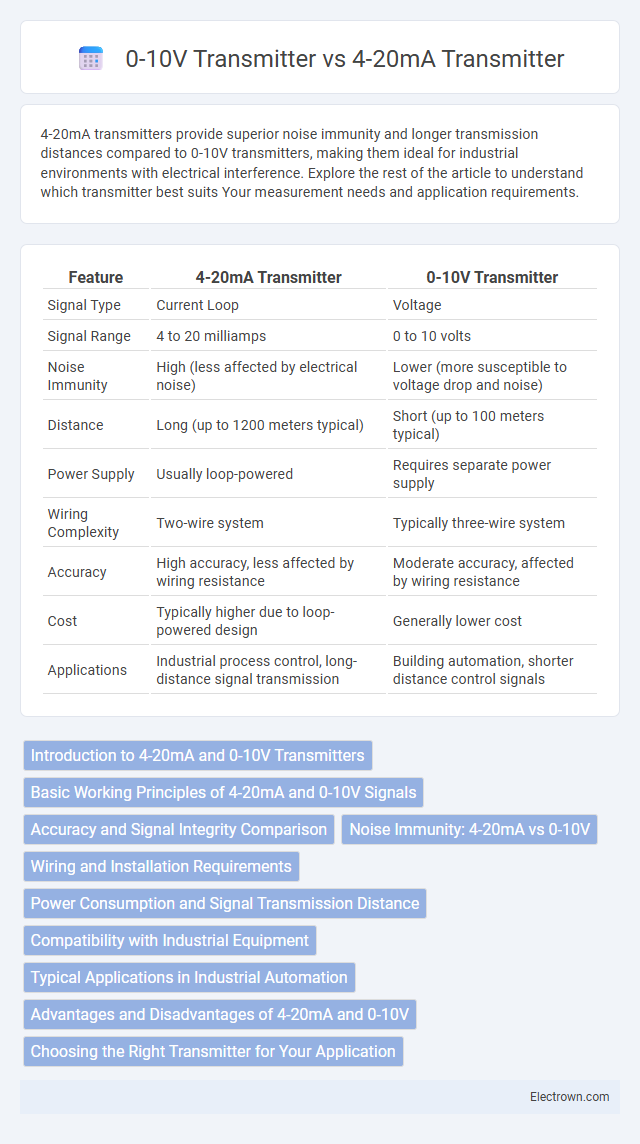

4-20mA transmitters provide superior noise immunity and longer transmission distances compared to 0-10V transmitters, making them ideal for industrial environments with electrical interference. Explore the rest of the article to understand which transmitter best suits Your measurement needs and application requirements.

Table of Comparison

| Feature | 4-20mA Transmitter | 0-10V Transmitter |

|---|---|---|

| Signal Type | Current Loop | Voltage |

| Signal Range | 4 to 20 milliamps | 0 to 10 volts |

| Noise Immunity | High (less affected by electrical noise) | Lower (more susceptible to voltage drop and noise) |

| Distance | Long (up to 1200 meters typical) | Short (up to 100 meters typical) |

| Power Supply | Usually loop-powered | Requires separate power supply |

| Wiring Complexity | Two-wire system | Typically three-wire system |

| Accuracy | High accuracy, less affected by wiring resistance | Moderate accuracy, affected by wiring resistance |

| Cost | Typically higher due to loop-powered design | Generally lower cost |

| Applications | Industrial process control, long-distance signal transmission | Building automation, shorter distance control signals |

Introduction to 4-20mA and 0-10V Transmitters

4-20mA transmitters are current loop devices widely used in industrial automation for their noise immunity and ability to transmit signals over long distances with minimal loss. In contrast, 0-10V transmitters operate on voltage signals, which are more susceptible to signal degradation and interference, making them suitable for shorter cable runs in less electrically noisy environments. Both types convert sensor data into analog signals, but 4-20mA loops offer enhanced reliability and accuracy in harsh industrial settings.

Basic Working Principles of 4-20mA and 0-10V Signals

4-20mA transmitters operate by varying current within a fixed loop to represent measurement values, ensuring signal integrity over long distances and resistance to electrical noise. In contrast, 0-10V transmitters use a voltage range output to convey the measurement, which can be more susceptible to signal degradation and interference in extended wiring. Understanding these basic working principles helps you select the appropriate transmitter type for reliable and accurate process control in industrial automation.

Accuracy and Signal Integrity Comparison

4-20mA transmitters provide higher accuracy and better signal integrity over long distances due to their current loop design, which is less susceptible to voltage drops and electrical noise compared to 0-10V transmitters. Voltage signal drops and interference commonly affect 0-10V transmitters, leading to reduced measurement precision especially in noisy industrial environments. The 4-20mA standard ensures consistent and reliable data transmission, making it preferable for critical process control applications requiring precise sensor feedback.

Noise Immunity: 4-20mA vs 0-10V

The 4-20mA transmitter offers superior noise immunity compared to the 0-10V transmitter due to its current-loop operation, which is less affected by electromagnetic interference and voltage drops over long cable runs. Voltage signals like 0-10V are more susceptible to signal degradation and noise because the signal amplitude can be easily altered by external disturbances and cable resistance. Industrial environments favor 4-20mA transmitters for accurate and stable data transmission in noisy conditions.

Wiring and Installation Requirements

4-20mA transmitters require two-wire or three-wire connections with current loops, making wiring more immune to electrical noise and suitable for longer cable runs up to 1,200 meters. In contrast, 0-10V transmitters typically use three-wire systems and are more susceptible to signal degradation over distances exceeding 100 meters, demanding careful shielding and grounding. Your choice between the two should consider the installation environment and distance to ensure signal integrity and ease of wiring.

Power Consumption and Signal Transmission Distance

4-20mA transmitters exhibit lower power consumption and support longer signal transmission distances, often exceeding 1000 meters, due to their current-loop design minimizing voltage drop impact. In contrast, 0-10V transmitters consume more power and are typically limited to shorter distances around 100 meters, as voltage signals degrade over longer cable runs. The inherent noise immunity of 4-20mA systems also enhances reliable data transmission in industrial environments.

Compatibility with Industrial Equipment

4-20mA transmitters are widely compatible with industrial automation systems due to their ability to maintain signal integrity over long distances and their resistance to electrical noise, making them ideal for harsh environments. In contrast, 0-10V transmitters, while simpler and cost-effective for short-range applications, are more susceptible to signal degradation and interference, limiting their effectiveness in complex industrial settings. Many programmable logic controllers (PLCs) and distributed control systems (DCS) natively support 4-20mA inputs, ensuring seamless integration with standard industrial equipment.

Typical Applications in Industrial Automation

The 4-20mA transmitter is widely used in industrial automation for process control due to its noise immunity and ability to transmit signals over long distances without signal degradation, making it ideal for temperature, pressure, and flow measurements. The 0-10V transmitter is preferred in applications requiring simple, low-cost voltage signal transmission, often found in HVAC systems and building automation where shorter cable runs and less susceptibility to electrical interference are acceptable. Both signal types integrate seamlessly with programmable logic controllers (PLCs) and distributed control systems (DCS), but the 4-20mA standard is favored in harsh industrial environments for reliable analog signal accuracy.

Advantages and Disadvantages of 4-20mA and 0-10V

The 4-20mA transmitter excels in noise immunity and long-distance signal transmission, making it ideal for industrial environments, but requires a power supply and may face signal loss in very long cable runs. The 0-10V transmitter offers simplicity and compatibility with low-cost controllers, but suffers from voltage drop over distance and higher susceptibility to electrical noise, limiting its accuracy and range. While 4-20mA supports live zero detection for troubleshooting sensor failures, 0-10V signals lack this feature, which makes 4-20mA more reliable for critical process control.

Choosing the Right Transmitter for Your Application

Choosing the right transmitter for your application depends on factors such as signal range, noise immunity, and wiring complexity. A 4-20mA transmitter offers superior noise resistance and can transmit signals over longer distances with simple two-wire connections, making it ideal for industrial environments. In contrast, a 0-10V transmitter requires careful wiring to avoid voltage drops and is better suited for shorter runs and less electrically noisy conditions.

4-20mA transmitter vs 0-10V transmitter Infographic

electrown.com

electrown.com