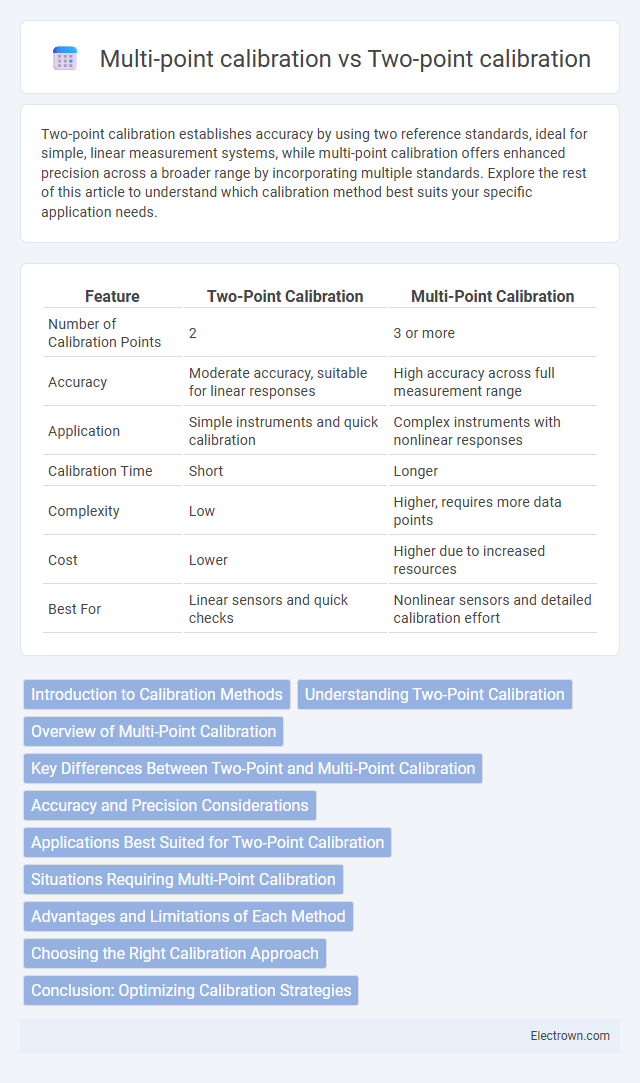

Two-point calibration establishes accuracy by using two reference standards, ideal for simple, linear measurement systems, while multi-point calibration offers enhanced precision across a broader range by incorporating multiple standards. Explore the rest of this article to understand which calibration method best suits your specific application needs.

Table of Comparison

| Feature | Two-Point Calibration | Multi-Point Calibration |

|---|---|---|

| Number of Calibration Points | 2 | 3 or more |

| Accuracy | Moderate accuracy, suitable for linear responses | High accuracy across full measurement range |

| Application | Simple instruments and quick calibration | Complex instruments with nonlinear responses |

| Calibration Time | Short | Longer |

| Complexity | Low | Higher, requires more data points |

| Cost | Lower | Higher due to increased resources |

| Best For | Linear sensors and quick checks | Nonlinear sensors and detailed calibration effort |

Introduction to Calibration Methods

Two-point calibration involves adjusting measurement instruments using two reference points to ensure accuracy over a specific range, providing a straightforward and cost-effective solution. Multi-point calibration utilizes multiple reference standards across the instrument's entire operating range, offering enhanced precision and reliability for complex or critical measurements. These methods are fundamental in industries like manufacturing, aerospace, and healthcare, where precise data integrity is essential.

Understanding Two-Point Calibration

Two-point calibration involves adjusting an instrument using two reference points, typically representing the minimum and maximum values within the measurement range, to ensure accuracy and linearity. This method is simpler and faster compared to multi-point calibration, which uses several reference points for higher precision and better error correction across the entire range. Understanding two-point calibration helps you quickly verify and maintain measurement accuracy in applications where linear behavior is expected.

Overview of Multi-Point Calibration

Multi-point calibration involves measuring and adjusting an instrument's response at multiple reference points across its operating range, providing higher accuracy and linearity than two-point calibration. This method is essential for applications requiring precise measurements over a broad spectrum, such as in analytical chemistry and sensor calibration. Your equipment benefits from multi-point calibration by ensuring optimal performance and reliability under varied conditions.

Key Differences Between Two-Point and Multi-Point Calibration

Two-point calibration uses two reference points to adjust measurement accuracy, ideal for simple systems with linear responses, while multi-point calibration employs multiple reference points across the measurement range for enhanced precision and accuracy in complex instruments. Multi-point calibration better compensates for non-linearities and provides a more detailed calibration curve, making it suitable for high-precision applications. Your choice between these methods affects the reliability of sensor readings and the overall quality of data analysis.

Accuracy and Precision Considerations

Two-point calibration offers basic accuracy by adjusting a measurement device at two reference points, but it may lack precision across a broader range of values due to potential non-linearity. Multi-point calibration enhances accuracy and precision by using multiple reference standards, creating a more detailed calibration curve that compensates for deviations across the entire measurement range. Laboratories requiring high-precision data prefer multi-point calibration to minimize systematic errors and improve measurement reliability.

Applications Best Suited for Two-Point Calibration

Two-point calibration is best suited for applications requiring quick, basic accuracy checks where the measurement range is limited and linearity is consistent, such as simple temperature sensors or pressure gauges. This method efficiently aligns the instrument with known reference points, making it ideal for routine maintenance in industrial processes, HVAC systems, and laboratory equipment. Your choice of two-point calibration ensures reliable performance without the complexity of multi-point methods, which are reserved for high-precision or non-linear measurement environments.

Situations Requiring Multi-Point Calibration

Situations requiring multi-point calibration arise when high precision across a broad measurement range is essential, such as in advanced laboratory analyses or manufacturing processes with stringent quality control standards. Complex instruments like spectrophotometers and gas analyzers benefit from multi-point calibration to correct nonlinear responses and ensure accuracy over various concentration levels. This method is crucial for applications involving diverse sample matrices or regulatory compliance demanding traceable and reproducible results.

Advantages and Limitations of Each Method

Two-point calibration offers simplicity and speed, making it ideal for routine checks where accuracy requirements are moderate; however, it may not sufficiently address nonlinearities in sensor response, leading to potential inaccuracies at intermediate values. Multi-point calibration enhances precision by using several reference points, allowing for better correction of sensor nonlinearities and improved overall accuracy, though it requires more time, resources, and complex equipment. Your choice between the two methods should consider the balance between calibration accuracy and operational efficiency based on application needs.

Choosing the Right Calibration Approach

Two-point calibration is ideal for applications requiring quick, basic accuracy checks between two known reference points, offering simplicity and efficiency. Multi-point calibration provides enhanced precision across a wider measurement range by using multiple reference points, making it suitable for high-accuracy instruments and critical performance assessments. Selecting the right calibration approach depends on the desired accuracy, measurement range, and the complexity of the device being calibrated.

Conclusion: Optimizing Calibration Strategies

Two-point calibration offers a quick and straightforward method for adjusting measurement devices, ideal for applications with limited accuracy requirements or stable environments. Multi-point calibration provides enhanced precision by accounting for non-linearities across the entire measurement range, making it essential for high-accuracy instruments and critical industries. Choosing the right calibration strategy depends on your specific accuracy needs, measurement environment, and resource availability, with multi-point calibration generally optimizing long-term reliability and performance.

Two-point calibration vs Multi-point calibration Infographic

electrown.com

electrown.com