BGA (Ball Grid Array) and LGA (Land Grid Array) are two types of CPU socket designs that differ primarily in how the processor connects to the motherboard, affecting installation and thermal performance. Understanding these differences will help you choose the right hardware for your needs--continue reading to explore the detailed comparison.

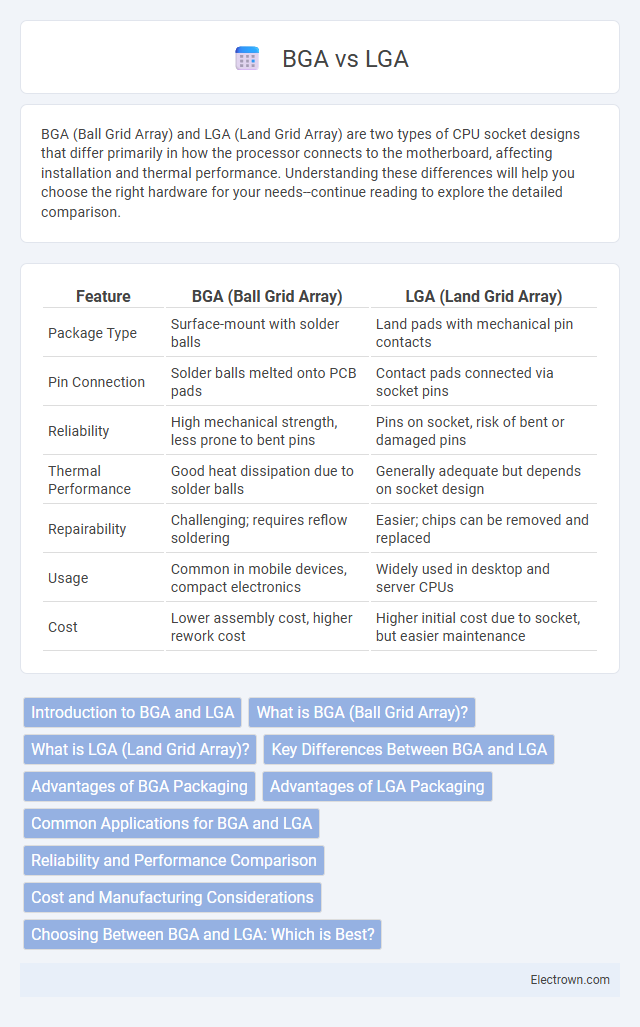

Table of Comparison

| Feature | BGA (Ball Grid Array) | LGA (Land Grid Array) |

|---|---|---|

| Package Type | Surface-mount with solder balls | Land pads with mechanical pin contacts |

| Pin Connection | Solder balls melted onto PCB pads | Contact pads connected via socket pins |

| Reliability | High mechanical strength, less prone to bent pins | Pins on socket, risk of bent or damaged pins |

| Thermal Performance | Good heat dissipation due to solder balls | Generally adequate but depends on socket design |

| Repairability | Challenging; requires reflow soldering | Easier; chips can be removed and replaced |

| Usage | Common in mobile devices, compact electronics | Widely used in desktop and server CPUs |

| Cost | Lower assembly cost, higher rework cost | Higher initial cost due to socket, but easier maintenance |

Introduction to BGA and LGA

BGA (Ball Grid Array) and LGA (Land Grid Array) are two common types of surface-mount packaging used for integrated circuits. BGA packages feature an array of solder balls on the underside for electrical connection, providing better heat dissipation and signal integrity. LGA uses flat contact pads that connect to the motherboard via spring-loaded pins or pads, offering ease of installation and reliable connections for high-performance processors.

What is BGA (Ball Grid Array)?

BGA (Ball Grid Array) is a type of surface-mount packaging used for integrated circuits, characterized by an array of solder balls arranged in a grid on the underside of the chip. This packaging enhances electrical performance and thermal conductivity by providing a shorter connection path and better heat dissipation compared to traditional pin-based packages. BGA is widely used in applications requiring high-density interconnections and improved reliability, such as CPUs, GPUs, and other advanced electronic devices.

What is LGA (Land Grid Array)?

LGA (Land Grid Array) is a type of surface-mount packaging used for integrated circuits, where the pins are located on the socket rather than the chip, ensuring a flat contact surface with the motherboard. This design improves signal performance and reduces the risk of pin damage during installation compared to traditional pin grid arrays. For your computer build, choosing LGA can enhance durability and ease of CPU installation.

Key Differences Between BGA and LGA

BGA (Ball Grid Array) packages feature solder balls on the underside that provide robust electrical connections directly to the PCB, whereas LGA (Land Grid Array) uses flat contact pads that press against corresponding pins on the socket. BGA allows for higher pin density and better heat dissipation, making it ideal for compact, high-performance devices, while LGA offers easier replacement and testing due to its socketed design. The primary difference lies in their mounting methods: BGA requires permanent soldering, limiting rework options, whereas LGA's socket interface facilitates removable connections.

Advantages of BGA Packaging

BGA packaging offers superior thermal performance and enhanced electrical conductivity due to its array of solder balls that provide multiple connection points, reducing signal inductance and resistance. Its compact design enables higher pin density, facilitating miniaturization and improved reliability in modern electronic devices. The robust mechanical connection of BGA also minimizes the risk of solder joint failure under thermal cycling and mechanical stress compared to LGA packages.

Advantages of LGA Packaging

LGA packaging offers superior electrical performance due to its shorter signal paths and improved contact reliability compared to BGA, making it ideal for high-frequency applications. The flat, land-grid design simplifies inspection and rework, reducing manufacturing defects and enhancing overall yield. Your systems benefit from increased thermal efficiency and better mechanical stability with LGA, supporting reliable operation under demanding conditions.

Common Applications for BGA and LGA

BGA (Ball Grid Array) packages are widely utilized in high-performance applications such as microprocessors, graphics cards, and mobile devices due to their superior thermal and electrical performance. LGA (Land Grid Array) packages commonly appear in server CPUs, desktop processors, and network equipment where reliable, high-density connections are essential. Both packaging types support advanced computing tasks but differ in soldering methods and mechanical support, making them suited for specific use cases in electronics manufacturing.

Reliability and Performance Comparison

BGA (Ball Grid Array) packages offer superior reliability due to their solder balls providing better heat dissipation and mechanical stability, which reduces the risk of crack formation under thermal stress. LGA (Land Grid Array) designs typically enable higher pin density and improved electrical performance through direct contact pads, supporting faster signal transmission and lower inductance. In high-frequency applications, LGA excels in performance, whereas BGA is preferred for durability in harsh environments.

Cost and Manufacturing Considerations

BGA (Ball Grid Array) packaging typically incurs higher upfront manufacturing costs due to complex soldering processes and specialized equipment, whereas LGA (Land Grid Array) offers cost advantages with simpler assembly and easier rework. BGA's dense ball matrix allows superior electrical performance and miniaturization, justifying higher production expenses in high-performance applications. LGA's flattened contact pads reduce manufacturing complexity and improve yield rates, making it a cost-effective choice for mainstream consumer electronics.

Choosing Between BGA and LGA: Which is Best?

Choosing between BGA (Ball Grid Array) and LGA (Land Grid Array) depends on your device's thermal requirements and assembly precision. BGA offers superior heat dissipation and is ideal for compact, high-performance electronics, while LGA provides easier inspection and rework capabilities, making it suitable for applications requiring frequent maintenance. Your choice should balance the need for reliability, manufacturability, and the specific performance demands of your project.

BGA vs LGA Infographic

electrown.com

electrown.com