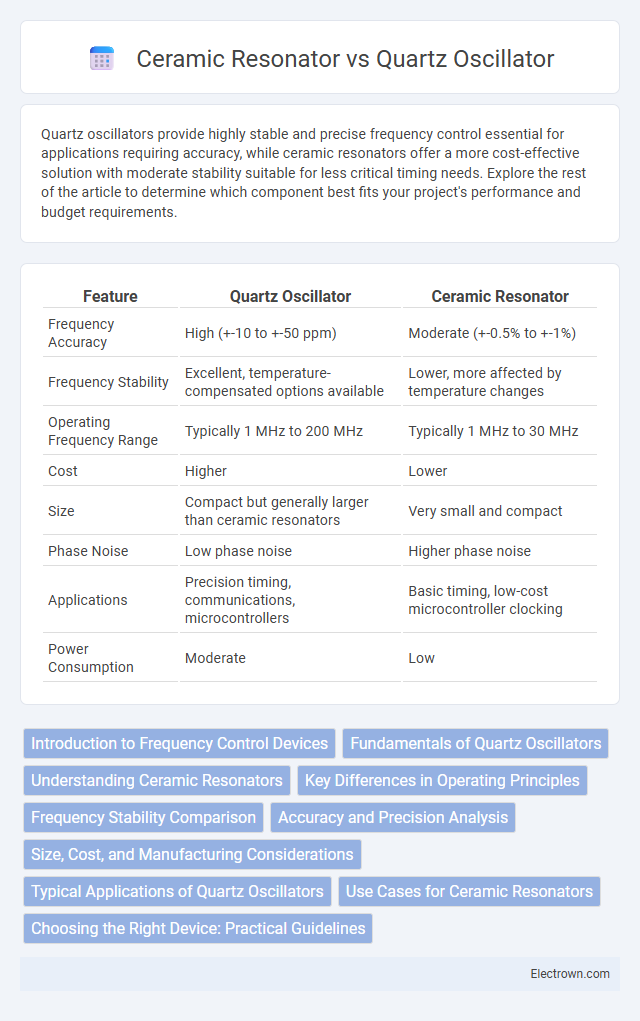

Quartz oscillators provide highly stable and precise frequency control essential for applications requiring accuracy, while ceramic resonators offer a more cost-effective solution with moderate stability suitable for less critical timing needs. Explore the rest of the article to determine which component best fits your project's performance and budget requirements.

Table of Comparison

| Feature | Quartz Oscillator | Ceramic Resonator |

|---|---|---|

| Frequency Accuracy | High (+-10 to +-50 ppm) | Moderate (+-0.5% to +-1%) |

| Frequency Stability | Excellent, temperature-compensated options available | Lower, more affected by temperature changes |

| Operating Frequency Range | Typically 1 MHz to 200 MHz | Typically 1 MHz to 30 MHz |

| Cost | Higher | Lower |

| Size | Compact but generally larger than ceramic resonators | Very small and compact |

| Phase Noise | Low phase noise | Higher phase noise |

| Applications | Precision timing, communications, microcontrollers | Basic timing, low-cost microcontroller clocking |

| Power Consumption | Moderate | Low |

Introduction to Frequency Control Devices

Quartz oscillators provide precise frequency control using the piezoelectric properties of quartz crystal, resulting in high stability and accuracy for electronic circuits. Ceramic resonators, made from piezoelectric ceramic material, offer a cost-effective solution with moderate frequency stability and faster start-up times. Your choice between these frequency control devices depends on the required precision, cost constraints, and application environment.

Fundamentals of Quartz Oscillators

Quartz oscillators rely on the piezoelectric properties of quartz crystals to generate highly stable and precise frequency signals, essential for timekeeping and communication devices. The crystal's natural resonance frequency is exploited by applying an electric field, causing mechanical vibrations that produce a consistent oscillation with minimal frequency drift. Compared to ceramic resonators, quartz oscillators offer superior accuracy, temperature stability, and long-term reliability, making them the preferred choice in precision electronics.

Understanding Ceramic Resonators

Ceramic resonators provide a cost-effective alternative to quartz oscillators with faster start-up times and moderate frequency stability, making them suitable for less precise timing applications. Unlike quartz oscillators that use quartz crystal's piezoelectric properties for high accuracy, ceramic resonators rely on ceramic materials exhibiting mechanical resonance. Your choice between these two components depends on the required frequency stability, cost constraints, and application sensitivity to timing variations.

Key Differences in Operating Principles

Quartz oscillators function by exploiting the piezoelectric effect in quartz crystals, where applied voltage induces precise mechanical vibrations that generate highly stable oscillation frequencies. Ceramic resonators rely on piezoelectric properties of ceramic materials, offering lower frequency stability and higher tolerance to environmental variations compared to quartz. The inherent material differences lead to quartz oscillators providing superior frequency accuracy and lower phase noise, while ceramic resonators are typically valued for cost-effectiveness and compact size in less critical timing applications.

Frequency Stability Comparison

Quartz oscillators offer superior frequency stability compared to ceramic resonators, with typical frequency deviations as low as +-10 ppm, whereas ceramic resonators generally exhibit +-0.5% to +-0.1% stability. This enhanced stability in quartz oscillators makes them ideal for applications requiring precise timing and minimal drift, such as in communication devices and high-performance clocks. Your choice between the two should consider the criticality of frequency accuracy and long-term reliability in your design.

Accuracy and Precision Analysis

Quartz oscillators provide superior accuracy and precision compared to ceramic resonators, with frequency stability commonly within +-10 ppm, while ceramic resonators typically range around +-0.5% to +-0.1%. The crystal lattice structure of quartz enables consistent oscillation frequency and low phase noise, crucial for applications demanding high timing accuracy. Your choice between the two depends on the required frequency stability, where quartz oscillators excel in precision-critical environments.

Size, Cost, and Manufacturing Considerations

Quartz oscillators typically offer higher frequency stability and precision compared to ceramic resonators, but they tend to be larger in size and more expensive due to the complex manufacturing process involving quartz crystal cutting and mounting. Ceramic resonators are smaller, cost-effective, and simpler to produce, making them suitable for consumer electronics where low cost and compactness outweigh tight frequency tolerance. Manufacturing considerations for quartz oscillators require strict quality control and cleanroom environments, whereas ceramic resonators benefit from bulk production with fewer process constraints, influencing their widespread use in mass-produced, cost-sensitive applications.

Typical Applications of Quartz Oscillators

Quartz oscillators are widely used in applications requiring high-frequency stability and precision timing, such as in microcontrollers, communication devices, and GPS systems. Their superior frequency accuracy and low phase noise make them ideal for clocks, radio transmitters, and frequency synthesizers. Your electronic design will benefit from quartz oscillators when precise timing and minimal drift are critical.

Use Cases for Ceramic Resonators

Ceramic resonators are commonly used in low-cost consumer electronics such as toys, remote controls, and small household appliances due to their affordability and moderate frequency stability. Their compact size and ability to operate in harsh environments make them suitable for automotive and industrial applications where tight frequency tolerances are less critical. Ceramic resonators excel in timing applications where cost efficiency and durability outweigh the need for ultra-precise frequency control.

Choosing the Right Device: Practical Guidelines

Quartz oscillators offer high frequency stability and precision, making them ideal for applications requiring accurate timing such as communication systems and microcontrollers. Ceramic resonators provide cost-effective solutions with moderate frequency stability, suitable for less demanding timing needs like simple clocks and consumer electronics. Your choice depends on balancing budget constraints against the need for precision, considering factors like frequency tolerance, temperature stability, and long-term reliability.

Quartz Oscillator vs Ceramic Resonator Infographic

electrown.com

electrown.com