Shared Body SOI technology integrates the body terminal across multiple transistors within a silicon-on-insulator (SOI) substrate to reduce parasitic capacitance, while Split Body SOI isolates each transistor's body to improve device performance and control leakage currents. Understanding these distinctions can optimize Your semiconductor design choices; read on to explore the detailed benefits and applications of each approach.

Table of Comparison

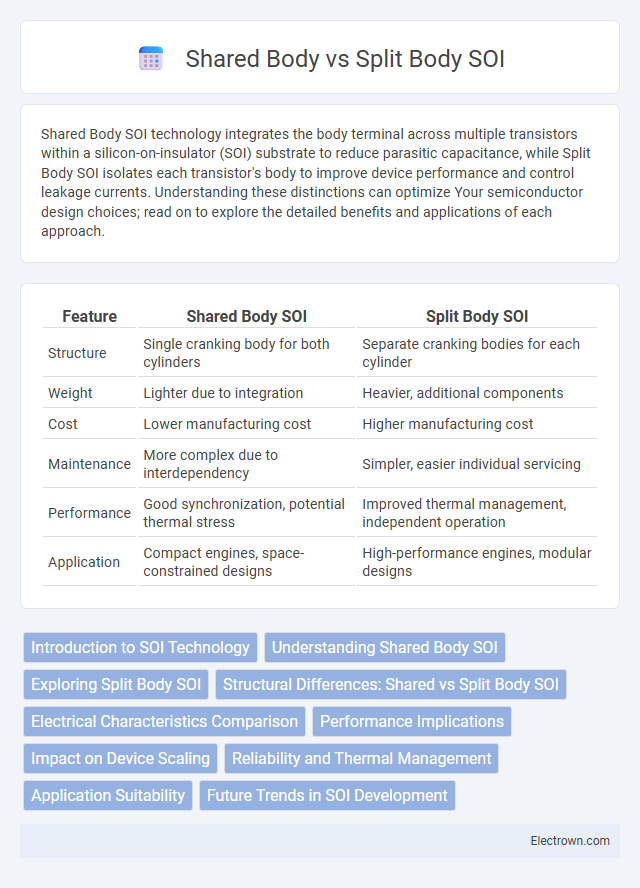

| Feature | Shared Body SOI | Split Body SOI |

|---|---|---|

| Structure | Single cranking body for both cylinders | Separate cranking bodies for each cylinder |

| Weight | Lighter due to integration | Heavier, additional components |

| Cost | Lower manufacturing cost | Higher manufacturing cost |

| Maintenance | More complex due to interdependency | Simpler, easier individual servicing |

| Performance | Good synchronization, potential thermal stress | Improved thermal management, independent operation |

| Application | Compact engines, space-constrained designs | High-performance engines, modular designs |

Introduction to SOI Technology

Silicon-On-Insulator (SOI) technology enhances semiconductor device performance by isolating the active silicon layer from the bulk substrate, reducing parasitic capacitance and improving speed. Shared Body SOI designs utilize a single silicon film for multiple transistors, optimizing area efficiency but potentially impacting device isolation and latch-up robustness. Split Body SOI, in contrast, provides separate silicon bodies for each transistor, offering superior isolation and device reliability, which can be critical for high-performance or low-power applications requiring precise control over your circuit behavior.

Understanding Shared Body SOI

Shared Body Silicon On Insulator (SOI) technology integrates multiple devices within a single silicon layer, enhancing circuit density and reducing parasitic capacitance. This approach improves power efficiency and switching speeds by minimizing the isolation overhead present in split body SOI structures. Understanding how Shared Body SOI impacts device performance can help you optimize semiconductor design for advanced electronic applications.

Exploring Split Body SOI

Split Body Silicon-On-Insulator (SOI) technology divides the transistor body into separate regions, enabling enhanced control over threshold voltage and reducing short-channel effects in advanced semiconductor devices. This architecture improves device performance by isolating the transistor channel from substrate interference, leading to lower leakage currents and better variability management compared to Shared Body SOI designs. Split Body SOI is particularly effective in scaling transistors for low-power and high-speed applications, making it a key technology in next-generation integrated circuits.

Structural Differences: Shared vs Split Body SOI

Shared Body SOI features a continuous silicon layer that connects multiple transistors, improving conductivity but increasing parasitic capacitance. Split Body SOI separates the transistor bodies with insulating regions, reducing leakage currents and enhancing device isolation for better performance. Your choice between Shared and Split Body SOI depends on trade-offs between integration density and electrical isolation requirements.

Electrical Characteristics Comparison

Shared Body and Split Body Silicon-On-Insulator (SOI) technologies differ significantly in electrical characteristics, influencing device performance and leakage currents. Shared Body SOI typically exhibits increased parasitic capacitance due to the common substrate, leading to higher junction capacitance and reduced switching speeds compared to Split Body SOI. Your choice impacts static leakage current, as Split Body SOI devices provide better body bias control, resulting in lower leakage and improved overall power efficiency in advanced CMOS circuits.

Performance Implications

Shared Body SOI transistors typically exhibit reduced parasitic capacitance, which enhances switching speeds and overall device performance compared to Split Body SOI. In contrast, Split Body SOI offers improved latch-up immunity and better body bias control, but this can introduce increased resistance and capacitance, potentially degrading high-frequency performance. Optimizing the choice between Shared and Split Body SOI depends on balancing speed requirements with robustness and power considerations in specific semiconductor applications.

Impact on Device Scaling

Shared Body SOI structures reduce parasitic capacitance by integrating a common substrate, enabling finer device scaling with lower leakage currents. Split Body SOI offers enhanced electrostatic control by isolating each transistor body, which can improve short-channel effects but may increase fabrication complexity. Your choice between Shared and Split Body SOI significantly influences scaling performance, particularly in advanced semiconductor nodes aiming for minimized power consumption and maximized speed.

Reliability and Thermal Management

Shared Body SOI offers improved thermal management by distributing heat evenly across the substrate, which minimizes hotspots and enhances overall device reliability under high-power conditions. Split Body SOI isolates device regions, reducing parasitic capacitance and allowing for better control of localized heating, thereby improving performance stability and extending device lifespan. Careful selection between Shared and Split Body SOI depends on application-specific thermal profiles and reliability requirements in advanced semiconductor manufacturing.

Application Suitability

Shared Body SOI technology is best suited for applications requiring cost efficiency and moderate isolation, making it ideal for consumer electronics and IoT devices. Split Body SOI offers superior isolation and reduced parasitic capacitance, which enhances high-frequency performance, benefiting RF and high-speed digital circuits. Your choice depends on whether your application prioritizes cost savings or high-performance electrical characteristics.

Future Trends in SOI Development

Future trends in SOI development emphasize enhanced performance through advanced Split Body SOI architectures, enabling improved device isolation and reduced parasitic capacitance compared to traditional Shared Body SOI structures. Emerging fabrication techniques support finer scalability and lower power consumption, critical for next-generation AI and IoT applications. Your choice of SOI technology will significantly impact integration density and thermal management as semiconductor demands evolve.

Shared Body vs Split Body SOI Infographic

electrown.com

electrown.com