Sintering and reflow are two distinct thermal processes used in electronics manufacturing to bond materials and components; sintering involves heating powdered materials below their melting point to form a solid mass, while reflow melts solder paste to create electrical connections. Discover how understanding the differences between sintering and reflow can improve your manufacturing outcomes by reading the rest of this article.

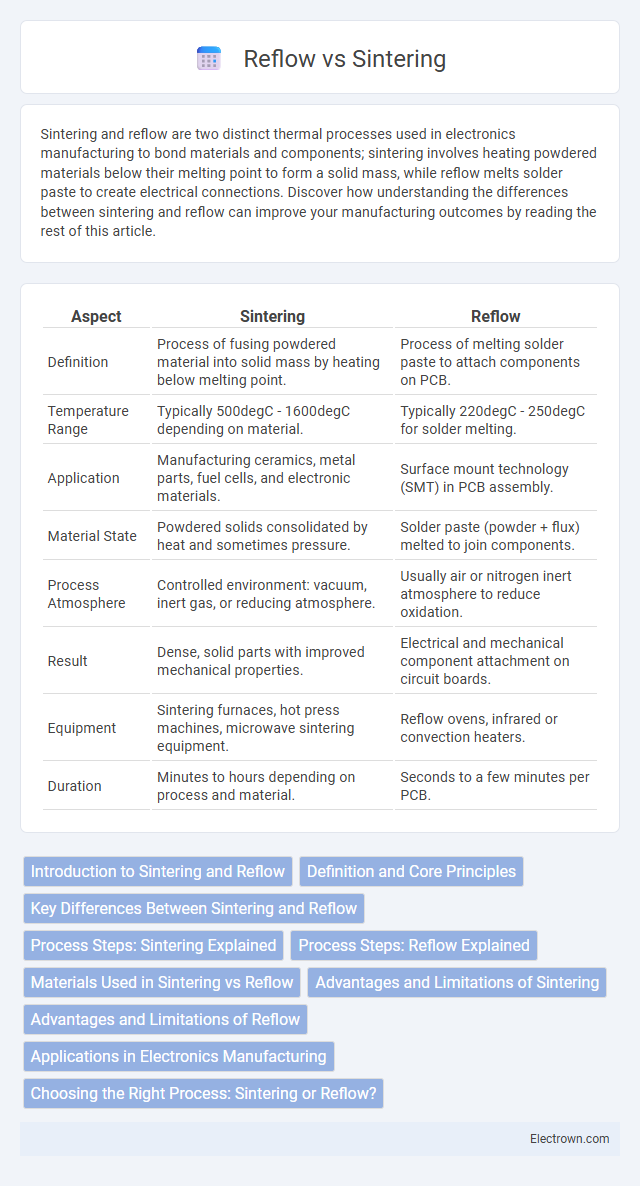

Table of Comparison

| Aspect | Sintering | Reflow |

|---|---|---|

| Definition | Process of fusing powdered material into solid mass by heating below melting point. | Process of melting solder paste to attach components on PCB. |

| Temperature Range | Typically 500degC - 1600degC depending on material. | Typically 220degC - 250degC for solder melting. |

| Application | Manufacturing ceramics, metal parts, fuel cells, and electronic materials. | Surface mount technology (SMT) in PCB assembly. |

| Material State | Powdered solids consolidated by heat and sometimes pressure. | Solder paste (powder + flux) melted to join components. |

| Process Atmosphere | Controlled environment: vacuum, inert gas, or reducing atmosphere. | Usually air or nitrogen inert atmosphere to reduce oxidation. |

| Result | Dense, solid parts with improved mechanical properties. | Electrical and mechanical component attachment on circuit boards. |

| Equipment | Sintering furnaces, hot press machines, microwave sintering equipment. | Reflow ovens, infrared or convection heaters. |

| Duration | Minutes to hours depending on process and material. | Seconds to a few minutes per PCB. |

Introduction to Sintering and Reflow

Sintering and reflow are essential thermal processes used in electronics manufacturing to join materials and components. Sintering involves heating powdered materials below their melting point to create a solid mass through atomic diffusion, commonly used for advanced packaging and high-reliability applications. Reflow, on the other hand, heats solder paste above its melting point to create electrical and mechanical connections on printed circuit boards, making it the standard method for surface mount technology assembly.

Definition and Core Principles

Sintering involves heating powdered materials just below their melting point to bond particles through diffusion, creating a solid mass with distinct microstructural properties. Reflow soldering uses controlled heating to melt solder paste, allowing components to form electrical and mechanical connections upon cooling. Both processes rely on precise thermal profiles but differ fundamentally in phase transitions and material behavior during bonding.

Key Differences Between Sintering and Reflow

Sintering involves bonding particles through heat without melting, creating solid structures ideal for metal and ceramic components, while reflow uses solder melting to join electronic parts on PCBs. You should choose sintering for high-strength, temperature-resistant joints, whereas reflow suits delicate, precise circuit assembly requiring low-temperature processing. The key differences lie in temperature ranges, material states during processing, and application fields like industrial manufacturing versus electronics assembly.

Process Steps: Sintering Explained

Sintering involves heating metal particles at temperatures below their melting point to bond them into a solid mass through diffusion, typically following a paste application step. The process steps for sintering include printing the conductive paste, drying to remove solvents, and heating in a controlled atmosphere where particles fuse together, forming a strong mechanical and electrical connection. Your choice between sintering and reflow should consider sintering's advantage in producing highly conductive and robust joints without fully melting the material.

Process Steps: Reflow Explained

Reflow soldering involves applying solder paste to circuit boards, placing components, and then heating the assembly in a reflow oven to melt the solder and create reliable electrical connections. The process includes controlled temperature profiles with preheating, soaking, reflow, and cooling stages to ensure precise temperature ramp-up and solidification of solder joints. You achieve strong, consistent bonds ideal for surface-mount technology by carefully managing these steps, distinguishing reflow from sintering methods.

Materials Used in Sintering vs Reflow

Sintering primarily uses metal nanoparticle pastes such as silver, copper, or nickel to form strong, conductive bonds through controlled heat and pressure, ideal for high-performance electronics. In contrast, reflow soldering relies on solder alloys composed of tin, lead (or lead-free alternatives like tin-silver-copper), and flux materials to melt and solidify electronic components onto printed circuit boards. The choice of materials directly impacts thermal conductivity, electrical performance, and reliability in semiconductor packaging and assembly processes.

Advantages and Limitations of Sintering

Sintering offers advantages such as lower processing temperatures and improved thermal and electrical conductivity compared to traditional reflow soldering methods. This technique enhances joint reliability and reduces thermal stress on components but may face limitations in processing speed and equipment cost. Your choice between sintering and reflow depends on balancing performance benefits with manufacturing constraints.

Advantages and Limitations of Reflow

Reflow soldering offers precise temperature control and uniform heating, enabling reliable solder joints on complex printed circuit boards (PCBs) with fine-pitch components. Its main advantages include high throughput, compatibility with a wide range of solder pastes, and adaptability to automated production lines, which significantly enhance manufacturing efficiency. However, reflow's limitations involve potential thermal stress on sensitive components, limited effectiveness with high melting point materials, and challenges in achieving optimal solder joint quality on uneven surfaces or heavily populated boards.

Applications in Electronics Manufacturing

Sintering is widely used in power electronics and semiconductor packaging due to its ability to create high-strength, thermally stable bonds with superior electrical conductivity. Reflow soldering dominates printed circuit board (PCB) assembly for surface-mount technology (SMT) components, ensuring precise melting and solidification of solder paste to form reliable joints. Both processes are critical in electronics manufacturing, with sintering preferred for high-reliability and high-temperature applications, while reflow is suited for mass production with fine-pitch components.

Choosing the Right Process: Sintering or Reflow?

Selecting between sintering and reflow depends on the application requirements, such as thermal conductivity, mechanical strength, and electrical performance. Sintering is preferred for high-reliability electronic components due to its superior joint strength and lower thermal resistance, ideal for power modules and automotive applications. Reflow is suitable for standard PCB assembly, offering cost-effective mass production with established process controls for solder paste melting and component attachment.

Sintering vs Reflow Infographic

electrown.com

electrown.com