Breakdown voltage is the maximum voltage a semiconductor device can withstand before it conducts uncontrollably, while punchthrough voltage refers to the voltage at which the depletion regions in a transistor extend and merge, causing a loss of control over the channel. Understanding the distinction between breakdown voltage and punchthrough voltage is crucial for designing reliable electronic circuits, so explore the rest of the article for a deeper insight into their differences and implications for your devices.

Table of Comparison

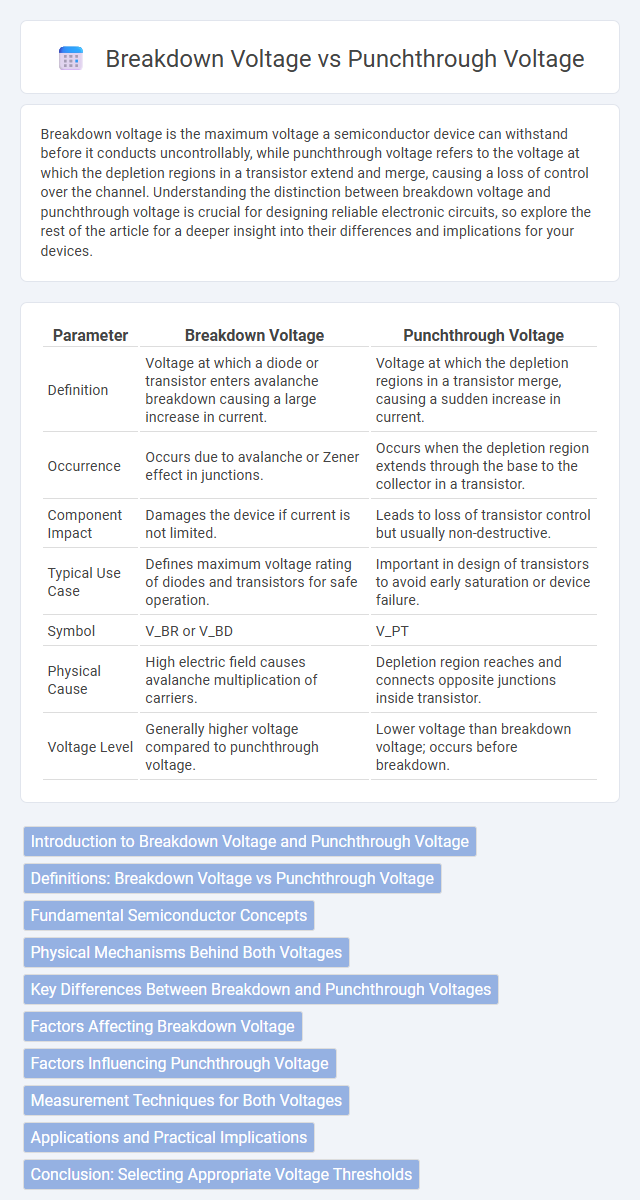

| Parameter | Breakdown Voltage | Punchthrough Voltage |

|---|---|---|

| Definition | Voltage at which a diode or transistor enters avalanche breakdown causing a large increase in current. | Voltage at which the depletion regions in a transistor merge, causing a sudden increase in current. |

| Occurrence | Occurs due to avalanche or Zener effect in junctions. | Occurs when the depletion region extends through the base to the collector in a transistor. |

| Component Impact | Damages the device if current is not limited. | Leads to loss of transistor control but usually non-destructive. |

| Typical Use Case | Defines maximum voltage rating of diodes and transistors for safe operation. | Important in design of transistors to avoid early saturation or device failure. |

| Symbol | V_BR or V_BD | V_PT |

| Physical Cause | High electric field causes avalanche multiplication of carriers. | Depletion region reaches and connects opposite junctions inside transistor. |

| Voltage Level | Generally higher voltage compared to punchthrough voltage. | Lower voltage than breakdown voltage; occurs before breakdown. |

Introduction to Breakdown Voltage and Punchthrough Voltage

Breakdown voltage refers to the critical voltage at which a semiconductor device undergoes avalanche or Zener breakdown, causing a sudden increase in current through the junction. Punchthrough voltage, on the other hand, is the voltage at which the depletion regions of adjacent junctions extend and merge, leading to unintended current flow beneath the transistor's channel. Understanding the distinction between breakdown voltage and punchthrough voltage is essential for designing reliable semiconductor devices with optimal voltage tolerance and performance.

Definitions: Breakdown Voltage vs Punchthrough Voltage

Breakdown voltage refers to the minimum voltage at which a semiconductor device undergoes avalanche breakdown, causing a significant increase in current and potential device failure. Punchthrough voltage is the voltage at which the depletion regions of the source and drain extend to each other in a transistor, leading to an uncontrollable current flow across the channel. Understanding the difference between breakdown voltage and punchthrough voltage helps you design more reliable and efficient semiconductor devices, as these voltages define critical limits for safe operation.

Fundamental Semiconductor Concepts

Breakdown voltage is the critical reverse voltage at which a semiconductor junction undergoes avalanche or Zener breakdown, leading to a sharp increase in current. Punchthrough voltage refers to the voltage at which the depletion regions of adjacent p-n junctions in a device merge, causing unintended current flow and loss of control over the device. Understanding the physical mechanisms behind breakdown voltage and punchthrough voltage is essential for designing robust semiconductor devices like MOSFETs and BJTs with optimized voltage handling capabilities.

Physical Mechanisms Behind Both Voltages

Breakdown voltage occurs when the electric field in a semiconductor junction becomes strong enough to cause avalanche multiplication, leading to a sudden increase in current, primarily driven by impact ionization. Punchthrough voltage is characterized by the depletion regions of the source and drain extending fully across the semiconductor channel, allowing charge carriers to flow uncontrollably due to the merging of depletion regions. Understanding these physical mechanisms helps you design devices to prevent premature failure by managing the electric field distribution and channel length effectively.

Key Differences Between Breakdown and Punchthrough Voltages

Breakdown voltage refers to the minimum reverse voltage at which a semiconductor device enters avalanche or Zener breakdown, causing a sudden increase in current. Punchthrough voltage occurs when the depletion regions around the p-n junction extend so far that they merge, allowing current to flow uncontrollably before the breakdown voltage is reached. The key difference lies in the physical mechanisms: breakdown voltage involves carrier multiplication due to high electric fields, while punchthrough voltage involves depletion region expansion leading to premature conduction.

Factors Affecting Breakdown Voltage

Breakdown voltage is primarily influenced by the doping concentration of the semiconductor material, device geometry, and temperature, with higher doping levels typically lowering the breakdown voltage due to increased electric field intensity. Punchthrough voltage depends on the depletion region width and the distance between the source and drain in devices like MOSFETs, where shorter channel lengths lead to reduced punchthrough voltage. Variations in material properties, electric field distribution, and junction depth critically affect both breakdown and punchthrough voltages in semiconductor devices.

Factors Influencing Punchthrough Voltage

Punchthrough voltage is influenced by factors such as doping concentration, depletion region width, and junction depth, which affect the electric field distribution within a semiconductor device. Higher doping concentrations and shallower junction depths typically reduce punchthrough voltage by enabling easier penetration of the depletion region under reverse bias. Understanding these parameters helps you optimize device design to prevent premature breakdown and improve reliability.

Measurement Techniques for Both Voltages

Breakdown voltage measurement typically involves applying a gradually increasing reverse bias to a semiconductor device until a sharp increase in reverse current indicates avalanche or Zener breakdown. Punchthrough voltage is measured by monitoring the transistor's collector current as the base-collector voltage increases, identifying the voltage where the depletion region extends through the base, causing a sudden rise in current due to substrate punchthrough. Your accurate assessment requires precision current-voltage (I-V) characterization equipment with controlled voltage ramp rates and temperature stability for both breakdown and punchthrough voltage testing.

Applications and Practical Implications

Breakdown voltage defines the maximum reverse voltage a semiconductor device can withstand before irreversible damage occurs, critical in power electronics and diode protection to ensure device reliability under high voltage conditions. Punchthrough voltage, on the other hand, identifies the threshold at which a depletion region extends through the device, impacting transistor switching behavior and limiting miniaturization in CMOS technology. Understanding these voltages helps you optimize device performance in applications such as voltage regulators, avalanche diodes, and high-speed transistors by balancing robustness and efficiency.

Conclusion: Selecting Appropriate Voltage Thresholds

Breakdown voltage defines the maximum reverse voltage a device can withstand before avalanche breakdown, while punchthrough voltage marks the onset of depletion region merging, leading to device failure. Understanding these thresholds is crucial for optimizing semiconductor performance and ensuring reliability in high-voltage applications. Selecting appropriate voltage thresholds for your design enhances device robustness and prevents premature failure caused by excessive bias conditions.

Breakdown Voltage vs Punchthrough Voltage Infographic

electrown.com

electrown.com