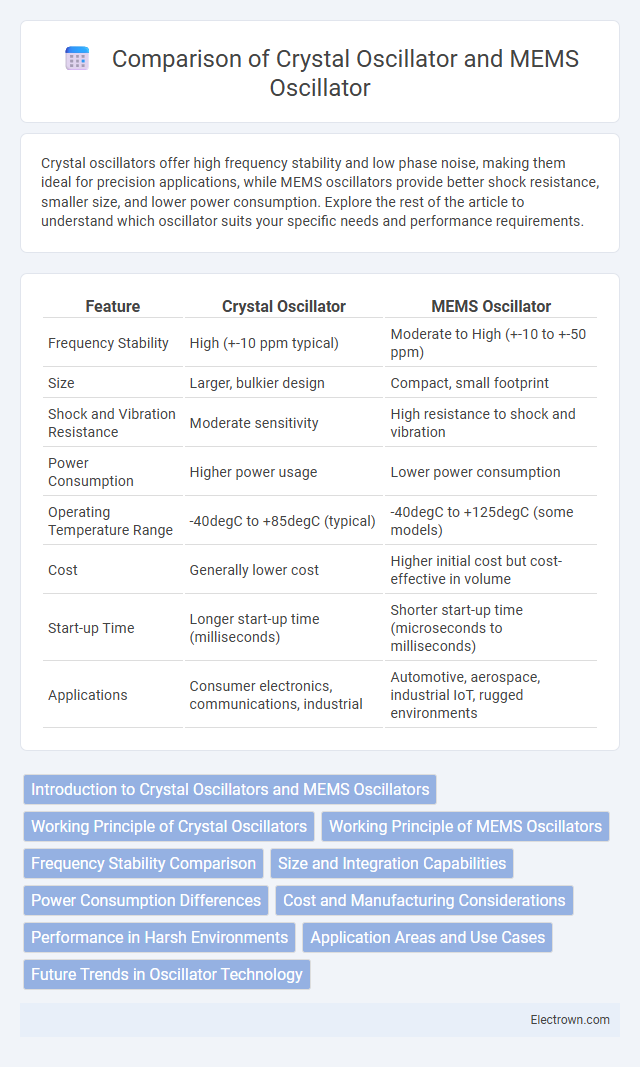

Crystal oscillators offer high frequency stability and low phase noise, making them ideal for precision applications, while MEMS oscillators provide better shock resistance, smaller size, and lower power consumption. Explore the rest of the article to understand which oscillator suits your specific needs and performance requirements.

Table of Comparison

| Feature | Crystal Oscillator | MEMS Oscillator |

|---|---|---|

| Frequency Stability | High (+-10 ppm typical) | Moderate to High (+-10 to +-50 ppm) |

| Size | Larger, bulkier design | Compact, small footprint |

| Shock and Vibration Resistance | Moderate sensitivity | High resistance to shock and vibration |

| Power Consumption | Higher power usage | Lower power consumption |

| Operating Temperature Range | -40degC to +85degC (typical) | -40degC to +125degC (some models) |

| Cost | Generally lower cost | Higher initial cost but cost-effective in volume |

| Start-up Time | Longer start-up time (milliseconds) | Shorter start-up time (microseconds to milliseconds) |

| Applications | Consumer electronics, communications, industrial | Automotive, aerospace, industrial IoT, rugged environments |

Introduction to Crystal Oscillators and MEMS Oscillators

Crystal oscillators utilize quartz crystals to generate stable, precise frequency signals through piezoelectric effects, making them essential in applications requiring high accuracy like communication systems and clocks. MEMS oscillators employ microelectromechanical systems technology, offering compact size, resistance to shock and vibration, and enhanced environmental robustness for modern devices. Your choice between crystal and MEMS oscillators depends on factors such as size constraints, frequency stability needs, and operating conditions.

Working Principle of Crystal Oscillators

Crystal oscillators operate based on the piezoelectric effect of quartz crystals, which generate a consistent mechanical vibration when an electric field is applied. This stable vibration frequency is used to produce precise oscillations in electronic circuits, essential for timing and frequency control. The quartz crystal acts as a resonant mechanical element, maintaining a fixed frequency with minimal drift over time and temperature variations.

Working Principle of MEMS Oscillators

MEMS oscillators operate using microelectromechanical systems that vibrate at precise frequencies, leveraging tiny mechanical resonators created through semiconductor fabrication techniques. Unlike traditional crystal oscillators that rely on quartz crystal vibrations, MEMS devices use silicon-based structures to achieve high stability and reliability under varying environmental conditions. Your choice of MEMS oscillators can enhance performance in applications requiring miniature size, shock resistance, and low power consumption.

Frequency Stability Comparison

Crystal oscillators exhibit superior frequency stability due to their reliance on quartz crystals with high Q-factors, maintaining consistent oscillation frequencies over temperature variations and aging. MEMS oscillators offer improved shock resistance and integration flexibility but typically have slightly lower frequency stability compared to traditional crystal oscillators. Your choice depends on the required precision, with crystal oscillators favored in applications demanding stringent frequency accuracy.

Size and Integration Capabilities

MEMS oscillators offer significantly smaller size and enhanced integration capabilities compared to traditional crystal oscillators, enabling more compact and complex circuit designs. Crystal oscillators often require discrete components and larger footprints due to their quartz crystal structure, limiting miniaturization in space-constrained applications. MEMS technology integrates oscillator functions within semiconductor processes, allowing seamless incorporation into System-on-Chip (SoC) solutions and reducing overall device size.

Power Consumption Differences

Crystal oscillators generally consume more power than MEMS oscillators due to their reliance on quartz crystal vibrations requiring continuous energy input. MEMS oscillators utilize microelectromechanical systems that operate at lower voltages and frequencies, significantly reducing power consumption in battery-powered and portable devices. Your choice of oscillator can impact device efficiency, with MEMS oscillators offering superior low-power performance ideal for modern, energy-sensitive applications.

Cost and Manufacturing Considerations

Crystal oscillators generally have lower unit costs due to established manufacturing processes and widespread availability of quartz material. MEMS oscillators leverage semiconductor fabrication techniques, enabling easier integration with ICs and mass production at potentially lower costs for high volumes. Your choice may depend on balancing initial production expenses with long-term scalability and application-specific requirements.

Performance in Harsh Environments

Crystal oscillators offer high frequency stability but are vulnerable to mechanical shock, vibration, and extreme temperature variations, limiting their reliability in harsh environments. MEMS oscillators exhibit superior resistance to shock, vibration, and wide temperature ranges due to their miniature silicon-based design, making them more robust for industrial and automotive applications. The inherent durability and environmental tolerance of MEMS oscillators ensure consistent performance where traditional quartz crystals may fail.

Application Areas and Use Cases

Crystal oscillators dominate in applications requiring high frequency stability and low phase noise, such as telecommunications, GPS devices, and precision instrumentation. MEMS oscillators excel in rugged environments and space-constrained designs like automotive electronics, IoT devices, and mobile handsets due to their small size and shock resistance. Your choice between the two depends on whether stability or durability aligns better with your device's specific operational needs.

Future Trends in Oscillator Technology

Crystal oscillators have long dominated timing solutions due to their high stability and low phase noise, but MEMS oscillators are rapidly advancing with improvements in temperature stability, shock resistance, and integration capabilities, making them ideal for IoT and wearable devices. Future trends indicate a shift towards MEMS technology as it offers greater miniaturization and lower power consumption, which aligns with the growing demand for compact and energy-efficient electronics. Your choice of oscillator technology should consider these evolving developments to ensure optimal performance and reliability in next-generation applications.

Crystal Oscillator vs MEMS Oscillator Infographic

electrown.com

electrown.com