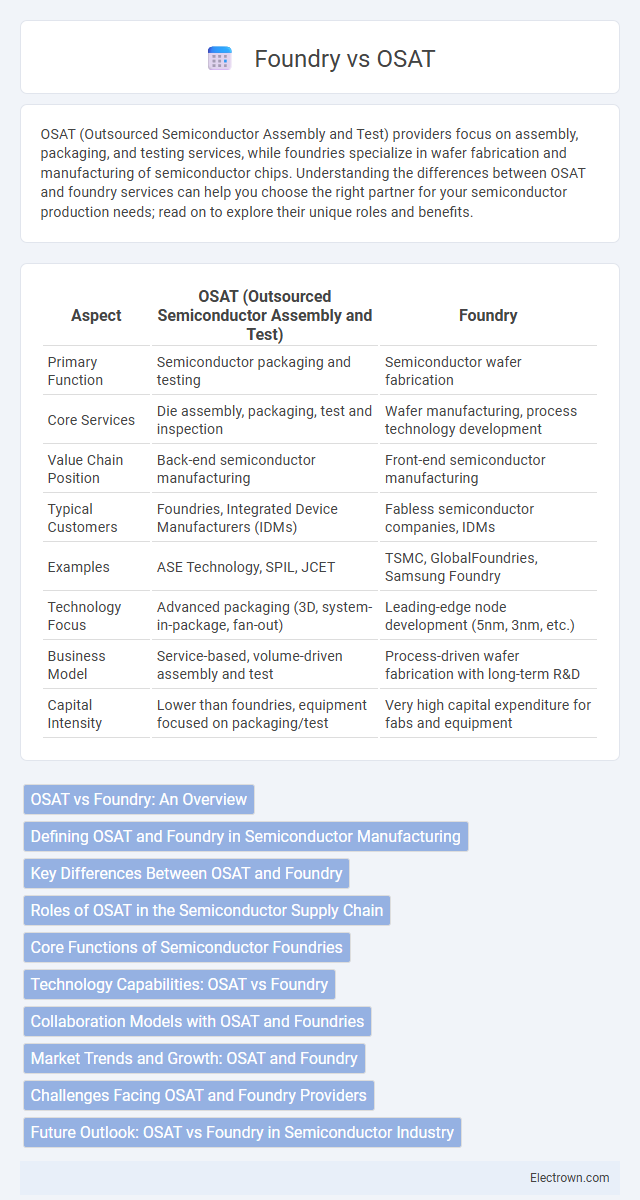

OSAT (Outsourced Semiconductor Assembly and Test) providers focus on assembly, packaging, and testing services, while foundries specialize in wafer fabrication and manufacturing of semiconductor chips. Understanding the differences between OSAT and foundry services can help you choose the right partner for your semiconductor production needs; read on to explore their unique roles and benefits.

Table of Comparison

| Aspect | OSAT (Outsourced Semiconductor Assembly and Test) | Foundry |

|---|---|---|

| Primary Function | Semiconductor packaging and testing | Semiconductor wafer fabrication |

| Core Services | Die assembly, packaging, test and inspection | Wafer manufacturing, process technology development |

| Value Chain Position | Back-end semiconductor manufacturing | Front-end semiconductor manufacturing |

| Typical Customers | Foundries, Integrated Device Manufacturers (IDMs) | Fabless semiconductor companies, IDMs |

| Examples | ASE Technology, SPIL, JCET | TSMC, GlobalFoundries, Samsung Foundry |

| Technology Focus | Advanced packaging (3D, system-in-package, fan-out) | Leading-edge node development (5nm, 3nm, etc.) |

| Business Model | Service-based, volume-driven assembly and test | Process-driven wafer fabrication with long-term R&D |

| Capital Intensity | Lower than foundries, equipment focused on packaging/test | Very high capital expenditure for fabs and equipment |

OSAT vs Foundry: An Overview

OSAT (Outsourced Semiconductor Assembly and Test) specializes in packaging and testing semiconductor devices, while foundries focus on manufacturing semiconductor wafers from design files. Your choice between OSAT and foundry depends on whether you need wafer fabrication or post-fabrication assembly and testing services. Foundries handle chip production, whereas OSAT providers complete the process with assembly, packaging, and quality testing to ensure ready-to-use semiconductor components.

Defining OSAT and Foundry in Semiconductor Manufacturing

OSAT (Outsourced Semiconductor Assembly and Test) companies specialize in packaging, assembly, and testing of semiconductor devices after wafer fabrication, playing a crucial role in ensuring device reliability and performance. Foundries concentrate on wafer fabrication, producing semiconductor wafers using advanced process technologies without engaging in chip design or final assembly. Your choice between OSAT and foundry services depends on whether you require manufacturing of semiconductor wafers or comprehensive post-fabrication assembly and testing solutions.

Key Differences Between OSAT and Foundry

OSAT (Outsourced Semiconductor Assembly and Test) specializes in semiconductor packaging and testing, while Foundries are focused on wafer fabrication and semiconductor manufacturing. The key difference lies in OSAT's role in assembling and verifying chip functionality post-fabrication, whereas Foundries handle the complex wafer processing and lithography before chips move to assembly. Your choice depends on whether you need manufacturing of wafers or advanced packaging and testing services.

Roles of OSAT in the Semiconductor Supply Chain

OSAT (Outsourced Semiconductor Assembly and Test) providers play a crucial role in the semiconductor supply chain by handling the packaging, testing, and assembly of semiconductor chips after fabrication by foundries. These services ensure the chips' performance reliability, protection from physical damage, and readiness for integration into electronic devices. You rely on OSAT partners to bridge the gap between manufacturing and final product deployment, enabling optimized production efficiency and quality assurance.

Core Functions of Semiconductor Foundries

Semiconductor foundries specialize in manufacturing integrated circuits (ICs) by fabricating wafers using advanced lithography, etching, and deposition techniques, ensuring high precision and scalability. Core functions include wafer fabrication, process development, and yield management, enabling the production of custom chips for various industries. Your choice between OSAT and foundry largely depends on whether you need chip manufacturing or assembly, testing, and packaging services.

Technology Capabilities: OSAT vs Foundry

OSAT (Outsourced Semiconductor Assembly and Test) providers specialize in advanced packaging technologies such as System-in-Package (SiP), wafer-level packaging, and 3D IC stacking, enabling high-density integration and improved thermal management. Foundries, on the other hand, concentrate on silicon wafer fabrication using cutting-edge process nodes like 3nm and 5nm, with strong capabilities in lithography, etching, and transistor engineering. While OSATs excel in post-fabrication assembly and testing innovations, foundries lead in front-end semiconductor manufacturing technology and process development.

Collaboration Models with OSAT and Foundries

Collaboration models with OSAT (Outsourced Semiconductor Assembly and Test) providers emphasize integrated services combining packaging, testing, and final assembly, streamlining supply chains for semiconductor manufacturers. Foundries focus primarily on wafer fabrication, requiring semiconductor companies to establish separate partnerships for assembly and testing stages, which can increase coordination complexity. You can optimize production efficiency by selecting the appropriate collaboration model based on project scale, technology requirements, and timeline constraints.

Market Trends and Growth: OSAT and Foundry

OSAT (Outsourced Semiconductor Assembly and Test) and Foundry markets are experiencing significant growth driven by the escalating demand for advanced semiconductor packaging and chip manufacturing technologies. The Foundry sector is expanding due to increased investment in cutting-edge process nodes and capacity scaling, while the OSAT market grows as more semiconductor companies outsource packaging and testing to capitalize on specialized expertise and cost efficiency. Your strategic positioning in these industries can benefit from understanding these trends, as the overall semiconductor market is projected to sustain robust double-digit growth fueled by diverse applications in AI, 5G, and automotive electronics.

Challenges Facing OSAT and Foundry Providers

OSAT providers encounter challenges such as managing complex packaging technologies and ensuring tight quality control for diverse semiconductor products. Foundry providers face intense competition in scaling process nodes while meeting increasing demands for advanced chip performance and yield optimization. Your choice between OSAT and foundry services depends on addressing supply chain integration and technological alignment with product specifications.

Future Outlook: OSAT vs Foundry in Semiconductor Industry

The future outlook of OSAT (Outsourced Semiconductor Assembly and Test) and Foundry services reveals a complementary growth trajectory driven by the increasing demand for advanced chip packaging and fabrication technologies. Foundries focus on semiconductor wafer fabrication, leveraging cutting-edge process nodes from companies like TSMC and Samsung, while OSAT providers specialize in complex packaging, testing, and final chip assembly, which are crucial as chip architectures grow more sophisticated. Your semiconductor strategy should consider integrating both OSAT and Foundry capabilities to optimize production efficiency, reduce costs, and accelerate time-to-market amid the industry's push towards AI, 5G, and IoT innovations.

OSAT vs Foundry Infographic

electrown.com

electrown.com