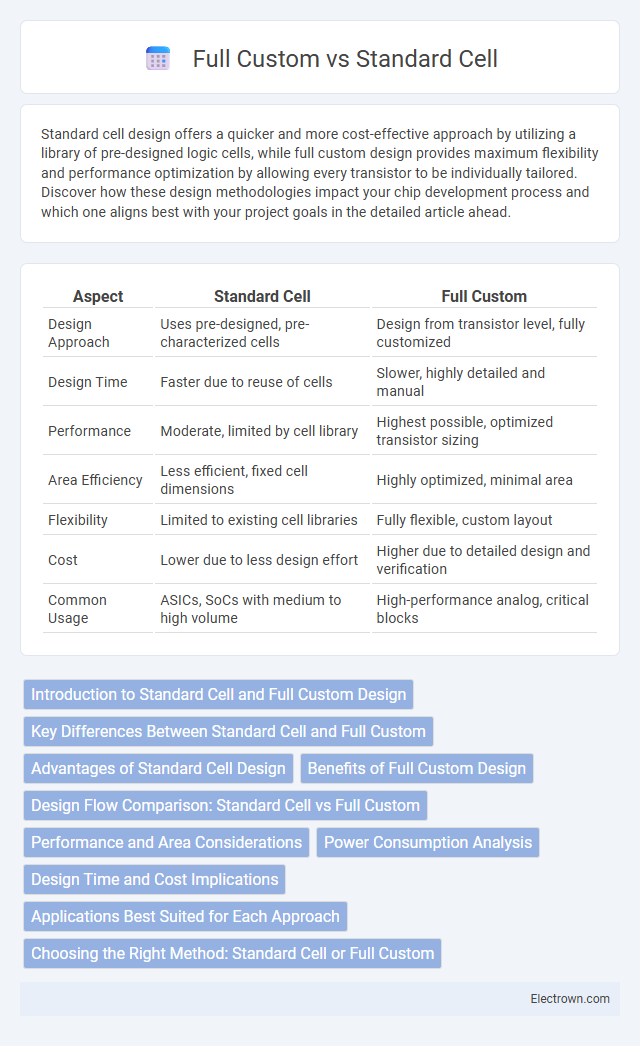

Standard cell design offers a quicker and more cost-effective approach by utilizing a library of pre-designed logic cells, while full custom design provides maximum flexibility and performance optimization by allowing every transistor to be individually tailored. Discover how these design methodologies impact your chip development process and which one aligns best with your project goals in the detailed article ahead.

Table of Comparison

| Aspect | Standard Cell | Full Custom |

|---|---|---|

| Design Approach | Uses pre-designed, pre-characterized cells | Design from transistor level, fully customized |

| Design Time | Faster due to reuse of cells | Slower, highly detailed and manual |

| Performance | Moderate, limited by cell library | Highest possible, optimized transistor sizing |

| Area Efficiency | Less efficient, fixed cell dimensions | Highly optimized, minimal area |

| Flexibility | Limited to existing cell libraries | Fully flexible, custom layout |

| Cost | Lower due to less design effort | Higher due to detailed design and verification |

| Common Usage | ASICs, SoCs with medium to high volume | High-performance analog, critical blocks |

Introduction to Standard Cell and Full Custom Design

Standard cell design uses pre-characterized logic gates and functional blocks arranged to create complex integrated circuits, offering faster development and easier scalability. Full custom design involves creating every transistor layout and circuit element from scratch, enabling highly optimized performance, power, and area but requiring significantly more design time. Both approaches balance trade-offs between design efficiency and optimization, impacting cost, design cycle, and chip performance.

Key Differences Between Standard Cell and Full Custom

Standard cell design uses pre-characterized logic gates for faster development and improved predictability, while full custom design involves creating each transistor layout individually for maximum performance and area optimization. Standard cells enable quicker time-to-market with moderate efficiency, whereas full custom designs offer superior speed and power efficiency but require significantly more design effort and time. Your choice depends on project priorities such as development speed, performance requirements, and resource availability.

Advantages of Standard Cell Design

Standard cell design offers faster development time due to pre-characterized libraries, enabling predictable performance and easier verification. It improves design scalability and reduces manufacturing risks by using reusable cells optimized for power, area, and speed. This approach also simplifies design automation, leading to lower costs and enhanced productivity in chip development.

Benefits of Full Custom Design

Full custom design offers unparalleled optimization of performance, power, and area by allowing designers to tailor transistor sizes and layouts precisely to the application's requirements. This approach results in higher speed and lower power consumption compared to standard cell designs, which rely on pre-defined blocks. Furthermore, full custom design enables unique device architectures and specialized analog or mixed-signal circuits that are unattainable with standard cells.

Design Flow Comparison: Standard Cell vs Full Custom

Standard Cell design flow employs pre-characterized library cells, enabling faster synthesis and verification through automated tools, which significantly reduces time-to-market. Full Custom design flow requires manual transistor-level design and layout, offering maximum performance optimization and area efficiency but demands extensive design effort and longer iteration cycles. Your choice between these approaches hinges on project constraints, balancing speed and flexibility against customization and optimal circuit performance.

Performance and Area Considerations

Standard cell design offers faster development times with moderate performance and area efficiency due to pre-characterized, fixed-height cells, enabling easier automation and predictable layout density. Full custom design achieves superior performance and area optimization by allowing tailored transistor sizing and custom layout, minimizing parasitics and maximizing speed and density at the cost of longer design cycles and higher complexity. Trade-offs between design time and the level of optimization needed dictate the choice, with full custom favored for critical high-performance and area-sensitive applications.

Power Consumption Analysis

Standard cell designs typically offer lower power consumption due to pre-characterized cells optimized for energy efficiency, enabling more predictable power analysis. Full custom designs allow finer control over transistor sizing and layout, which can achieve even lower power usage but require extensive expertise and time to optimize effectively. Your choice depends on whether you prioritize rapid development with moderate power savings or maximum power efficiency with detailed custom optimization.

Design Time and Cost Implications

Standard cell design significantly reduces design time and cost by utilizing pre-characterized, reusable logic cells, allowing faster development cycles and lower engineering expenses. Full custom design demands extensive manual effort and longer development time as each transistor layout is tailored, resulting in higher upfront costs but optimizing performance and area for specialized applications. Your choice depends on balancing budget constraints and project timelines against desired performance and customization levels.

Applications Best Suited for Each Approach

Standard cell design is best suited for large-scale digital integrated circuits where time-to-market, cost efficiency, and predictable performance are crucial, such as in processors, memory blocks, and ASICs for consumer electronics. Full custom design excels in applications requiring maximum performance, power efficiency, and area optimization, ideal for high-frequency analog circuits, RF components, and cutting-edge microprocessors. Your choice depends on balancing design flexibility with development time and resource constraints.

Choosing the Right Method: Standard Cell or Full Custom

Choosing between Standard Cell and Full Custom design methods depends on your project's priorities for performance, cost, and time-to-market. Standard Cell offers faster development and lower upfront costs by using pre-designed, verified logic blocks, making it ideal for moderate performance requirements and rapid prototyping. Full Custom design maximizes optimization and performance by tailoring every transistor, suitable for high-performance, low-power applications where design flexibility outweighs increased development time and cost.

Standard Cell vs Full Custom Infographic

electrown.com

electrown.com