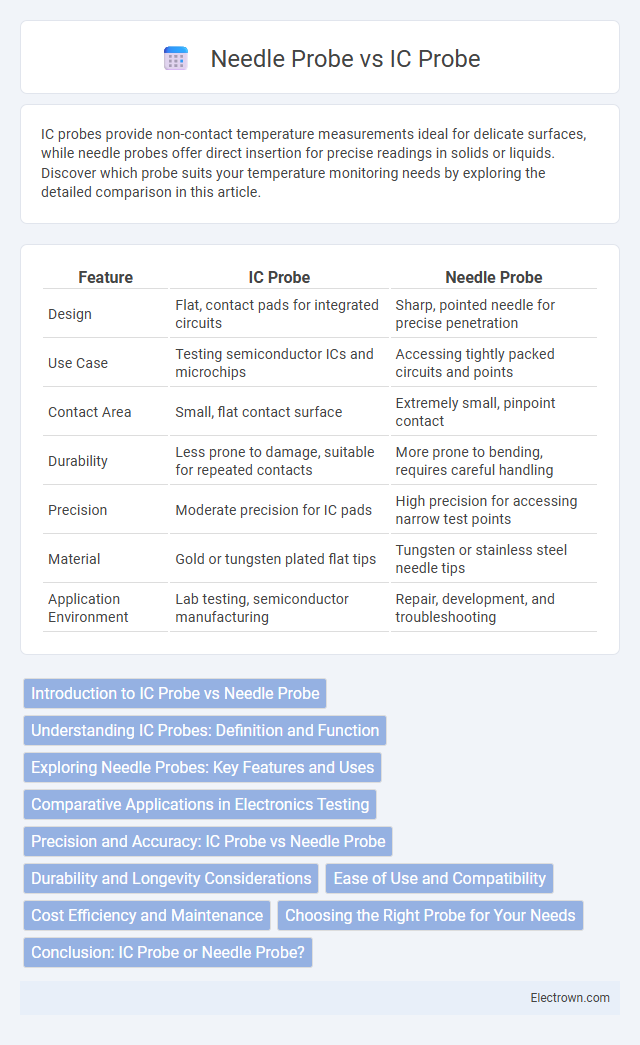

IC probes provide non-contact temperature measurements ideal for delicate surfaces, while needle probes offer direct insertion for precise readings in solids or liquids. Discover which probe suits your temperature monitoring needs by exploring the detailed comparison in this article.

Table of Comparison

| Feature | IC Probe | Needle Probe |

|---|---|---|

| Design | Flat, contact pads for integrated circuits | Sharp, pointed needle for precise penetration |

| Use Case | Testing semiconductor ICs and microchips | Accessing tightly packed circuits and points |

| Contact Area | Small, flat contact surface | Extremely small, pinpoint contact |

| Durability | Less prone to damage, suitable for repeated contacts | More prone to bending, requires careful handling |

| Precision | Moderate precision for IC pads | High precision for accessing narrow test points |

| Material | Gold or tungsten plated flat tips | Tungsten or stainless steel needle tips |

| Application Environment | Lab testing, semiconductor manufacturing | Repair, development, and troubleshooting |

Introduction to IC Probe vs Needle Probe

IC probes and needle probes are essential tools in semiconductor testing and diagnostics, each designed for specific applications in electronics manufacturing. IC probes provide precise contact with integrated circuit pads or bumps, enabling accurate signal measurement without damaging delicate components. Needle probes offer versatility with sharp tips that penetrate oxide layers or make contact with fine-pitched circuit elements, making them ideal for probing printed circuit boards (PCBs) and exposed leads.

Understanding IC Probes: Definition and Function

IC probes are specialized tools designed for testing and measuring integrated circuits (ICs) by making precise contact with tiny circuit points without damaging the component. These probes enable high-frequency signal analysis and debugging in semiconductor device development and manufacturing processes. Compared to needle probes, IC probes offer enhanced accuracy and stability due to their optimized contact geometry and reduced mechanical stress on IC surfaces.

Exploring Needle Probes: Key Features and Uses

Needle probes excel in precise temperature measurement within small or confined spaces due to their slender, pointed design, allowing rapid thermal response and minimal surface disruption. Common applications include food safety testing, medical diagnostics, and industrial process monitoring where accurate, localized readings are critical. Their durability and ability to penetrate various materials distinguish them from IC probes, which primarily interface with integrated circuits for electrical testing.

Comparative Applications in Electronics Testing

IC probes are primarily designed for testing integrated circuits with high precision on semiconductor wafers, enabling fine-pitch contact and high-frequency signal measurement. Needle probes, featuring sharp metallic tips, excel in PCB-level testing for establishing temporary contact points on solder pads and components during functional verification and fault diagnosis. Both tools complement each other in electronics testing by addressing different scales and stages of device inspection, with IC probes suited for micro-scale wafer probing and needle probes optimized for macro-scale circuit board analysis.

Precision and Accuracy: IC Probe vs Needle Probe

IC probes deliver higher precision and accuracy by directly contacting integrated circuit pads with minimal signal distortion, ensuring reliable electrical measurements in micro-scale testing environments. Needle probes, while versatile and cost-effective, may introduce slight inconsistencies due to larger tip sizes and potential misalignment during contact, affecting measurement accuracy. Your choice between IC and needle probes should prioritize the required measurement fidelity and the intricacy of the circuit under test.

Durability and Longevity Considerations

IC probes feature robust construction with high-quality materials designed to withstand frequent use in semiconductor testing, offering superior durability compared to needle probes. Needle probes tend to wear out faster due to their fine tips, which are prone to bending and breakage over time, reducing their longevity. Choosing an IC probe can enhance Your testing reliability by minimizing downtime related to probe replacement and maintenance.

Ease of Use and Compatibility

IC probes offer superior ease of use with their compact design tailored for integrated circuits, allowing precise contact with small test points on densely packed boards. Needle probes, while versatile for various applications, can be less user-friendly due to their fine, pointed tips that require steady handling and may struggle with compatibility on modern microelectronic components. Your choice depends on the testing environment, with IC probes providing efficient compatibility for surface-mounted devices and needle probes better suited for general-purpose probing tasks.

Cost Efficiency and Maintenance

IC probes generally offer higher cost efficiency due to their longer lifespan and lower maintenance requirements compared to needle probes, which are more prone to damage and frequent replacements. Maintenance for IC probes is simplified by their robust design and reduced risk of contamination, lowering your overall service expenses. Investing in an IC probe can significantly reduce downtime and operational costs while maintaining accurate testing results.

Choosing the Right Probe for Your Needs

IC probes provide precise electrical testing for integrated circuits with minimal invasiveness, making them ideal for delicate microelectronics. Needle probes, featuring sharp tips, excel in accessing tight spaces and robust contact points, suitable for PCB testing and general-purpose measurements. Evaluating your application's sensitivity and spatial constraints ensures you select the right probe that optimizes accuracy and durability.

Conclusion: IC Probe or Needle Probe?

IC Probe delivers higher precision and better contact reliability for integrated circuit testing, making it ideal for fine-pitch and high-frequency measurements. Needle Probe offers greater versatility and durability for general-purpose probing on a variety of electronic components and PCB testing. Choose IC Probe for advanced semiconductor analysis, while Needle Probe suits broader, routine electronic diagnostics.

IC Probe vs Needle Probe Infographic

electrown.com

electrown.com