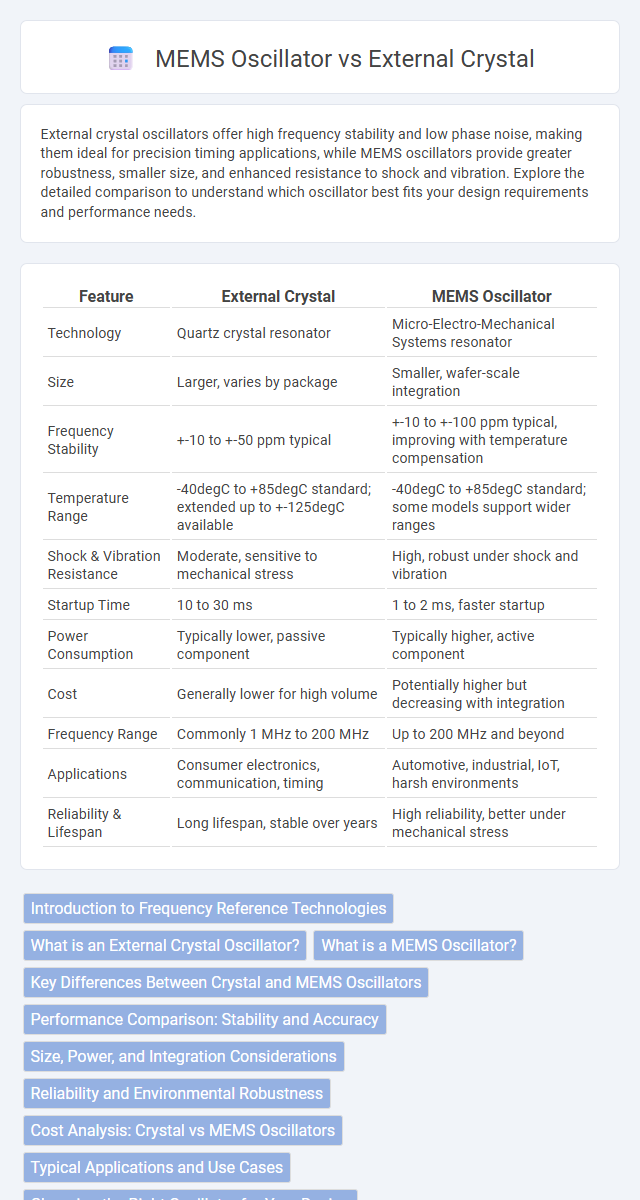

External crystal oscillators offer high frequency stability and low phase noise, making them ideal for precision timing applications, while MEMS oscillators provide greater robustness, smaller size, and enhanced resistance to shock and vibration. Explore the detailed comparison to understand which oscillator best fits your design requirements and performance needs.

Table of Comparison

| Feature | External Crystal | MEMS Oscillator |

|---|---|---|

| Technology | Quartz crystal resonator | Micro-Electro-Mechanical Systems resonator |

| Size | Larger, varies by package | Smaller, wafer-scale integration |

| Frequency Stability | +-10 to +-50 ppm typical | +-10 to +-100 ppm typical, improving with temperature compensation |

| Temperature Range | -40degC to +85degC standard; extended up to +-125degC available | -40degC to +85degC standard; some models support wider ranges |

| Shock & Vibration Resistance | Moderate, sensitive to mechanical stress | High, robust under shock and vibration |

| Startup Time | 10 to 30 ms | 1 to 2 ms, faster startup |

| Power Consumption | Typically lower, passive component | Typically higher, active component |

| Cost | Generally lower for high volume | Potentially higher but decreasing with integration |

| Frequency Range | Commonly 1 MHz to 200 MHz | Up to 200 MHz and beyond |

| Applications | Consumer electronics, communication, timing | Automotive, industrial, IoT, harsh environments |

| Reliability & Lifespan | Long lifespan, stable over years | High reliability, better under mechanical stress |

Introduction to Frequency Reference Technologies

External crystal oscillators use quartz crystals to generate highly stable frequency references based on the piezoelectric effect, providing precise timing for electronic systems. MEMS oscillators leverage microelectromechanical systems technology to achieve frequency stability with smaller size, lower power consumption, and improved vibration resistance. Both technologies serve as essential frequency reference sources, but MEMS oscillators offer advantages in robustness and integration for modern applications.

What is an External Crystal Oscillator?

An external crystal oscillator is a precise timing device that uses a quartz crystal to generate stable frequency signals critical for electronic circuits. It provides high frequency accuracy and low phase noise, making it ideal for applications requiring reliable clock sources such as microcontrollers, communication systems, and consumer electronics. Your choice of an external crystal oscillator can significantly impact the performance and stability of your electronic system by ensuring consistent signal timing.

What is a MEMS Oscillator?

A MEMS oscillator is a microelectromechanical system device that generates precise clock signals by using a vibrating mechanical structure at the micro-scale instead of a traditional quartz crystal. Unlike external crystals that rely on quartz's piezoelectric properties, MEMS oscillators integrate resonators and frequency control circuitry on a single silicon chip, offering enhanced durability, smaller size, and improved resistance to shock and vibration. These devices are widely used in telecommunications, consumer electronics, and automotive applications requiring stable timing solutions in harsh environments.

Key Differences Between Crystal and MEMS Oscillators

External crystals rely on quartz vibrating at a precise frequency to provide a stable clock signal, while MEMS oscillators use microelectromechanical systems to generate frequencies with enhanced durability and resistance to shock and vibration. Crystals offer high frequency accuracy and low phase noise but are more susceptible to environmental factors such as temperature changes and mechanical stress. Your choice between the two depends on the application requirements for size, robustness, frequency stability, and power consumption.

Performance Comparison: Stability and Accuracy

MEMS oscillators typically offer superior performance in stability and accuracy compared to external crystals due to their integrated design that mitigates environmental influences such as temperature fluctuations and mechanical shock. External crystal oscillators provide high frequency stability but can suffer from aging and sensitivity to vibration, limiting their long-term precision. MEMS oscillators exhibit enhanced robustness with stable frequency output over a wider temperature range and improved resistance to shock and vibration, making them ideal for applications demanding consistent timing accuracy.

Size, Power, and Integration Considerations

MEMS oscillators offer significantly smaller size compared to traditional external crystals, enabling compact PCB designs essential for modern electronics. They consume lower power due to advanced semiconductor fabrication and integrated voltage regulation, enhancing battery life in portable devices. Integration considerations favor MEMS oscillators as they provide improved vibration tolerance, built-in temperature compensation, and easier system-level integration versus standalone external crystals.

Reliability and Environmental Robustness

MEMS oscillators offer superior reliability and environmental robustness compared to external crystals due to their solid-state construction, which makes them less susceptible to mechanical shock and vibration. External crystals are prone to frequency drift and failure under extreme temperature changes and physical stress. MEMS devices typically maintain stable frequency performance across a wider temperature range and harsh environmental conditions, improving overall system reliability.

Cost Analysis: Crystal vs MEMS Oscillators

External crystals generally offer lower unit costs due to mature manufacturing processes and widespread adoption in consumer electronics, making them cost-effective for high-volume applications. MEMS oscillators, while higher in initial price, provide enhanced reliability and integration benefits that can reduce overall system costs through lower failure rates and simplified design requirements. Evaluating total cost of ownership reveals MEMS technology may be more economical in harsh environments or long-life products despite a higher upfront expense.

Typical Applications and Use Cases

External crystals are widely used in applications requiring high frequency stability and low phase noise, such as precision timekeeping in wristwatches, GPS devices, and communication equipment. MEMS oscillators excel in harsh environments with high shock and vibration resistance, making them ideal for automotive systems, industrial machinery, and aerospace applications. Your choice depends on the specific demands of your device, balancing factors like environmental robustness and signal accuracy.

Choosing the Right Oscillator for Your Design

Selecting the right oscillator for your design hinges on factors such as frequency stability, phase noise, and environmental resilience. External crystals offer precise frequency control and low phase noise, making them ideal for applications requiring high accuracy and low jitter. MEMS oscillators provide superior shock resistance, smaller size, and better temperature performance, making them suitable for rugged or compact designs where reliability under harsh conditions is critical.

External Crystal vs MEMS Oscillator Infographic

electrown.com

electrown.com