SOIC packages feature a wider body and larger lead pitch, making them easier to handle and solder manually, while TSSOP packages offer a more compact design with finer lead pitch, ideal for saving PCB space in high-density applications. To understand which package best suits Your project's requirements for assembly and performance, read on to explore the key differences between SOIC and TSSOP.

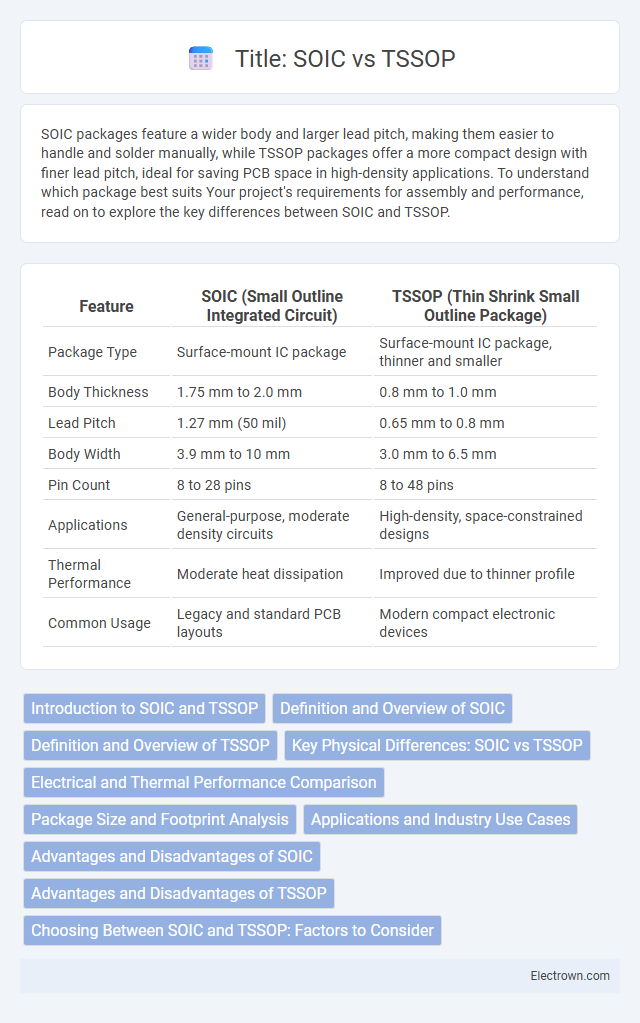

Table of Comparison

| Feature | SOIC (Small Outline Integrated Circuit) | TSSOP (Thin Shrink Small Outline Package) |

|---|---|---|

| Package Type | Surface-mount IC package | Surface-mount IC package, thinner and smaller |

| Body Thickness | 1.75 mm to 2.0 mm | 0.8 mm to 1.0 mm |

| Lead Pitch | 1.27 mm (50 mil) | 0.65 mm to 0.8 mm |

| Body Width | 3.9 mm to 10 mm | 3.0 mm to 6.5 mm |

| Pin Count | 8 to 28 pins | 8 to 48 pins |

| Applications | General-purpose, moderate density circuits | High-density, space-constrained designs |

| Thermal Performance | Moderate heat dissipation | Improved due to thinner profile |

| Common Usage | Legacy and standard PCB layouts | Modern compact electronic devices |

Introduction to SOIC and TSSOP

SOIC (Small Outline Integrated Circuit) and TSSOP (Thin Shrink Small Outline Package) are popular surface-mount IC packaging types used in electronics manufacturing. SOIC packages feature a wider body and lead spacing typically around 1.27 mm, making them easier to handle in prototyping, while TSSOP packages have a slimmer profile and more closely spaced leads, generally about 0.65 mm, allowing for higher pin counts in compact designs. Both packages offer reliable solderability and thermal performance but serve different needs based on PCB space constraints and device complexity.

Definition and Overview of SOIC

SOIC (Small Outline Integrated Circuit) is a surface-mount package characterized by its gull-wing leads extending from two sides of a rectangular body, commonly used for integrated circuits in electronics. Compared to TSSOP (Thin Shrink Small Outline Package), SOIC components typically have a larger footprint and lead pitch, making them easier to handle in manual soldering but less suitable for high-density applications. The SOIC package balances compact size with ease of assembly, offering a reliable option for moderate pin count ICs in consumer and industrial electronics.

Definition and Overview of TSSOP

TSSOP (Thin Shrink Small Outline Package) is a surface-mount IC package known for its reduced thickness and smaller footprint compared to SOIC (Small Outline Integrated Circuit). This package type offers better thermal performance and higher pin density, making it ideal for space-constrained applications. Choosing a TSSOP can optimize Your PCB design by enabling more compact layouts while maintaining reliable electrical connections.

Key Physical Differences: SOIC vs TSSOP

SOIC (Small Outline Integrated Circuit) packages are generally thicker and have a wider body compared to TSSOP (Thin Shrink Small Outline Package), making TSSOP more suitable for compact designs due to its reduced height and narrower width. The lead pitch in TSSOP is typically finer, often around 0.65mm or less, whereas SOIC lead pitches usually range from 1.27mm, allowing for higher pin count density in TSSOP packages. Understanding these key physical differences helps you select the right package for your PCB layout constraints and assembly requirements.

Electrical and Thermal Performance Comparison

SOIC packages generally offer lower thermal resistance and higher power dissipation compared to TSSOP due to their larger body size and lead pitch, enabling better heat dissipation in high-power applications. Electrical performance-wise, TSSOPs feature shorter lead lengths which reduce parasitic inductance and capacitance, improving signal integrity and making them suitable for high-frequency circuits. Thermal conductivity in SOICs benefits from larger exposed lead frames, whereas TSSOPs rely more heavily on PCB thermal design to manage heat effectively.

Package Size and Footprint Analysis

SOIC (Small Outline Integrated Circuit) packages typically have larger footprints compared to TSSOP (Thin Shrink Small Outline Package) due to wider pin spacing and thicker body size, making SOIC less ideal for compact circuit boards. TSSOP packages offer smaller footprints and finer pitch, often ranging between 0.5mm to 0.65mm pin spacing, enabling higher component density and space-saving on PCBs. Designers prioritize TSSOP for applications requiring miniaturization, while SOIC remains favored for ease of manual soldering and prototyping due to its larger dimensions.

Applications and Industry Use Cases

SOIC (Small Outline Integrated Circuit) packages are widely used in automotive, consumer electronics, and industrial control systems due to their robust design and ease of manual soldering. TSSOP (Thin Shrink Small Outline Package) is favored in high-density applications such as smartphones, medical devices, and telecommunications equipment because of its smaller footprint and enhanced pin count. Your choice between SOIC and TSSOP should consider space constraints and the need for thermal management in specific industry use cases.

Advantages and Disadvantages of SOIC

SOIC (Small Outline Integrated Circuit) packages offer advantages such as a robust dual in-line structure, easier manual soldering due to wider lead pitch, and better mechanical stability compared to TSSOP (Thin Shrink Small Outline Package). However, SOIC packages tend to be larger, consume more PCB space, and provide lower pin density, which can limit their use in high-density or miniaturized electronics. Your choice of SOIC is ideal when reliability and ease of assembly outweigh the need for compactness and higher pin counts.

Advantages and Disadvantages of TSSOP

TSSOP (Thin Shrink Small Outline Package) offers advantages such as a significantly smaller footprint and reduced height compared to SOIC (Small Outline Integrated Circuit), enabling higher component density on PCBs. Its thin profile enhances thermal dissipation and electrical performance, making it ideal for compact and high-frequency applications. However, TSSOP can be more challenging to handle and solder manually due to its finer pitch, increasing the risk of solder bridging and requiring precise equipment for assembly.

Choosing Between SOIC and TSSOP: Factors to Consider

Choosing between SOIC and TSSOP packages depends on factors such as PCB space constraints, pin count, and thermal performance requirements. SOIC packages typically offer easier hand soldering and better mechanical durability, while TSSOP packages provide a smaller footprint with higher pin density, ideal for compact designs. Your decision should weigh the trade-offs in assembly complexity, electrical characteristics, and available board real estate.

SOIC vs TSSOP Infographic

electrown.com

electrown.com