Edge contact offers a smaller contact area focusing force on a precise point, ideal for high-pressure applications, while surface contact distributes pressure over a larger area, enhancing stability and reducing wear. Discover which contact method best suits your specific needs by exploring the detailed comparison in the rest of this article.

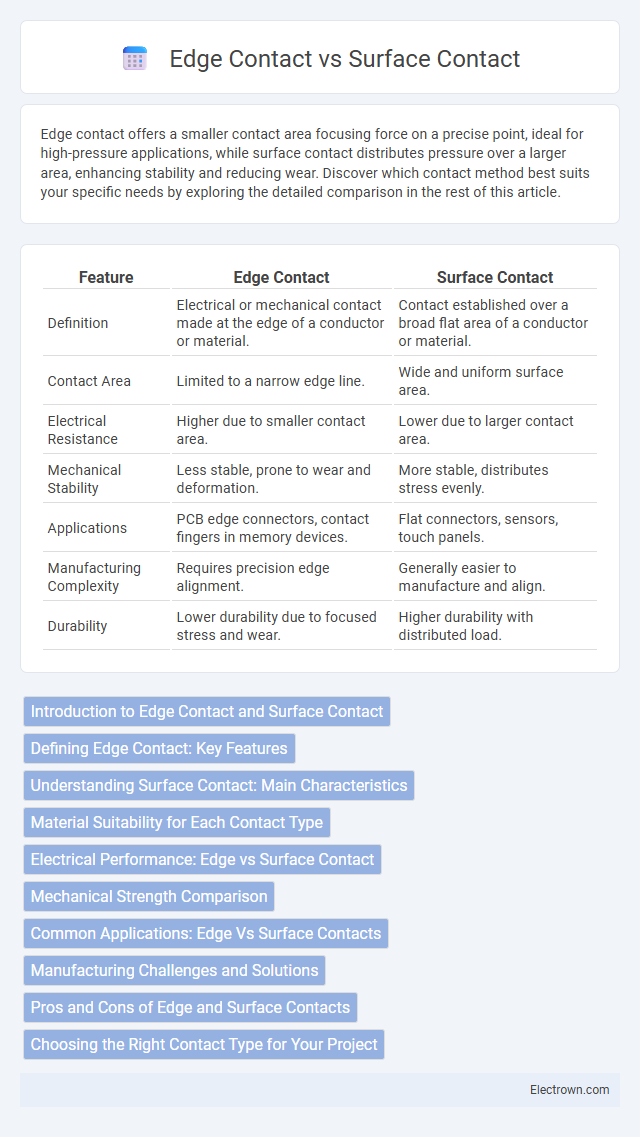

Table of Comparison

| Feature | Edge Contact | Surface Contact |

|---|---|---|

| Definition | Electrical or mechanical contact made at the edge of a conductor or material. | Contact established over a broad flat area of a conductor or material. |

| Contact Area | Limited to a narrow edge line. | Wide and uniform surface area. |

| Electrical Resistance | Higher due to smaller contact area. | Lower due to larger contact area. |

| Mechanical Stability | Less stable, prone to wear and deformation. | More stable, distributes stress evenly. |

| Applications | PCB edge connectors, contact fingers in memory devices. | Flat connectors, sensors, touch panels. |

| Manufacturing Complexity | Requires precision edge alignment. | Generally easier to manufacture and align. |

| Durability | Lower durability due to focused stress and wear. | Higher durability with distributed load. |

Introduction to Edge Contact and Surface Contact

Edge contact refers to the method where two components meet along a narrow, linear boundary, typically resulting in concentrated stress and higher pressure points. Surface contact involves a broader area of interaction between parts, distributing forces more evenly and reducing localized wear. Understanding the differences between edge contact and surface contact is crucial in designing mechanical systems, bearings, and seals to optimize performance and durability.

Defining Edge Contact: Key Features

Edge contact refers to the connection where electrical or mechanical components meet along a thin, linear boundary, enabling precise signal transmission or force distribution. Key features include minimal contact area, higher contact pressure, and enhanced alignment accuracy, which reduce resistance and improve performance in high-frequency or high-precision applications. This contrasts with surface contact, which involves a broader contact area offering greater stability but potentially increased resistance and less sensitivity to alignment.

Understanding Surface Contact: Main Characteristics

Surface contact involves the interaction between two bodies across a broad, flat area, resulting in a larger contact patch that distributes load more evenly and reduces stress concentrations. It typically provides higher stability and better wear resistance due to the extensive contact surface, enhancing durability in mechanical and electronic applications. Surface contact is favored in designs requiring efficient heat dissipation and consistent electrical conductivity, making it ideal for interfaces such as solder joints and bearing surfaces.

Material Suitability for Each Contact Type

Edge contact is best suited for hard, wear-resistant materials like steel or carbide due to its concentrated load-bearing nature, which demands high surface hardness to prevent deformation. Surface contact is more appropriate for softer or less rigid materials such as aluminum or plastic, as it distributes the load over a larger area, reducing stress and minimizing potential damage. Selecting the right contact type based on material properties ensures optimal performance and longevity in mechanical applications.

Electrical Performance: Edge vs Surface Contact

Edge contact provides a lower electrical resistance and improved signal integrity compared to surface contact due to a larger contact area and direct connection to the conductive layers. Surface contact often suffers from increased contact resistance and potential signal degradation caused by surface contaminants or oxidation. For optimal electrical performance in high-frequency or high-current applications, your design should prioritize edge contact technology.

Mechanical Strength Comparison

Edge contact provides superior mechanical strength due to the concentrated load distribution along the contact line, resulting in higher resistance to shear and bending forces. Surface contact distributes forces over a larger area, which reduces the stress concentration but may lead to lower overall strength in applications requiring precise alignment and high load capacity. Your choice between edge and surface contact should consider the specific mechanical demands and durability requirements of the application.

Common Applications: Edge Vs Surface Contacts

Edge contacts are commonly used in high-density electronic connectors and printed circuit boards where precise alignment and minimal signal interference are crucial. Surface contacts dominate in applications requiring broader contact areas, such as touchscreens, membrane switches, and wearable sensors, ensuring reliable electrical conductivity over larger surfaces. Both contact types are essential in modern electronics, with edge contacts favoring compact, high-performance uses and surface contacts suited for flexible, durable interface technologies.

Manufacturing Challenges and Solutions

Edge contact in electronic components presents manufacturing challenges such as precise alignment requirements and higher risk of mechanical stress, demanding advanced lithography and deposition techniques to ensure reliability. Surface contact manufacturing faces issues with maintaining uniform pressure distribution and consistent conductivity over larger areas, often mitigated by using compliant materials and controlled surface treatments. Solutions to both include adopting automated assembly systems, enhanced quality control measures, and employing novel materials like conductive adhesives to improve contact integrity and reduce defects.

Pros and Cons of Edge and Surface Contacts

Edge contact connectors provide superior signal integrity and reduced crosstalk due to their direct electrical paths, making them ideal for high-speed applications, but they often require precise alignment and can be more costly to manufacture. Surface contact connectors offer easier assembly and greater mechanical tolerance, which enhances durability and reduces production costs, yet they may suffer from higher contact resistance and potential signal degradation in high-frequency environments. Selecting between edge and surface contact depends on balancing performance requirements with cost and mechanical constraints.

Choosing the Right Contact Type for Your Project

Selecting the appropriate contact type between edge contact and surface contact depends on the specific electrical and mechanical requirements of your project. Edge contact is ideal for applications needing compact connectors with reliable signal integrity and minimal insertion loss, commonly used in high-speed data transmission. Surface contact offers greater contact area and mechanical stability, making it suitable for power delivery and sensors requiring robust and consistent connections.

Edge contact vs Surface contact Infographic

electrown.com

electrown.com