Nanoelectromechanical Systems (NEMS) operate at a nanoscale, offering greater sensitivity, faster response times, and lower power consumption compared to Microelectromechanical Systems (MEMS), which function at a microscale and are widely used in various commercial applications. Explore the rest of the article to understand how these technologies impact your industry and which system suits your specific needs.

Table of Comparison

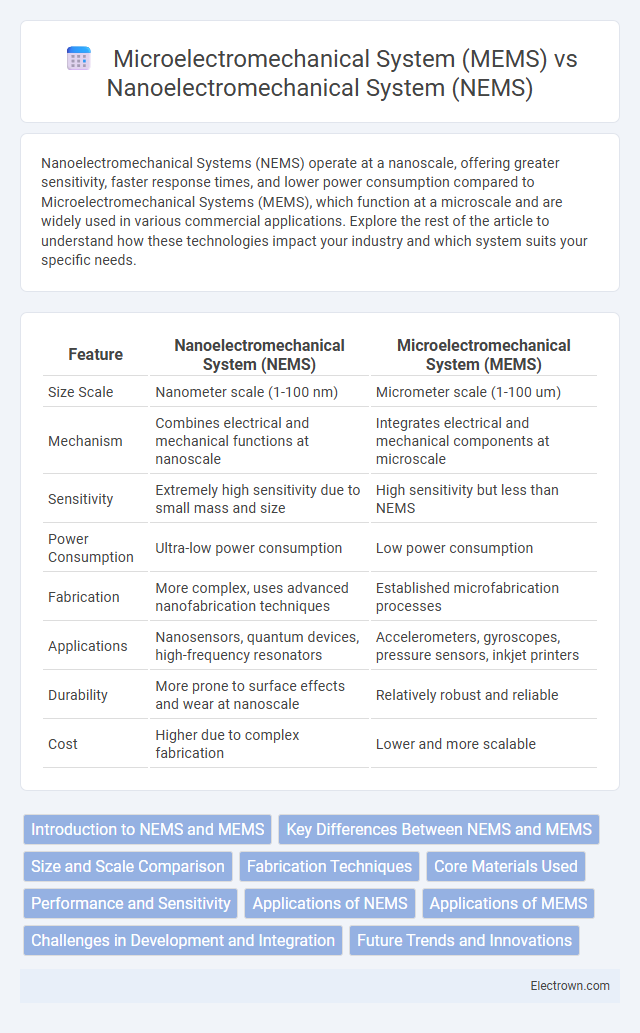

| Feature | Nanoelectromechanical System (NEMS) | Microelectromechanical System (MEMS) |

|---|---|---|

| Size Scale | Nanometer scale (1-100 nm) | Micrometer scale (1-100 um) |

| Mechanism | Combines electrical and mechanical functions at nanoscale | Integrates electrical and mechanical components at microscale |

| Sensitivity | Extremely high sensitivity due to small mass and size | High sensitivity but less than NEMS |

| Power Consumption | Ultra-low power consumption | Low power consumption |

| Fabrication | More complex, uses advanced nanofabrication techniques | Established microfabrication processes |

| Applications | Nanosensors, quantum devices, high-frequency resonators | Accelerometers, gyroscopes, pressure sensors, inkjet printers |

| Durability | More prone to surface effects and wear at nanoscale | Relatively robust and reliable |

| Cost | Higher due to complex fabrication | Lower and more scalable |

Introduction to NEMS and MEMS

Nanoelectromechanical Systems (NEMS) and Microelectromechanical Systems (MEMS) are technologies that integrate electrical and mechanical components at the nanoscale and microscale, respectively. NEMS operate at dimensions below 100 nanometers, enabling ultrahigh sensitivity and faster response times compared to MEMS, which typically range from 1 to 100 micrometers and are widely used in sensors, actuators, and communication devices. Innovations in silicon fabrication and nanomaterials drive advancements in both NEMS and MEMS, supporting their applications in healthcare, environmental monitoring, and advanced electronics.

Key Differences Between NEMS and MEMS

Nanoelectromechanical Systems (NEMS) operate at the nanometer scale, offering higher sensitivity and faster response times compared to Microelectromechanical Systems (MEMS), which function at the micrometer scale. NEMS devices leverage quantum effects and exhibit lower power consumption, while MEMS are typically more robust and easier to integrate with existing semiconductor technologies. The fabrication challenges in NEMS often involve advanced nanolithography, whereas MEMS rely on mature microfabrication techniques, impacting cost and scalability.

Size and Scale Comparison

Nanoelectromechanical Systems (NEMS) operate at the nanometer scale, typically ranging from 1 to 100 nanometers, enabling ultra-sensitive mechanical sensing and faster response times compared to Microelectromechanical Systems (MEMS), which function at micrometer scales typically between 1 and 100 micrometers. The significantly smaller size of NEMS allows for higher integration density, lower power consumption, and enhanced performance in applications such as molecular detection and quantum devices. In contrast, MEMS are widely used in larger-scale applications like accelerometers, pressure sensors, and inkjet printer heads, where moderate precision and robustness are required.

Fabrication Techniques

Nanoelectromechanical Systems (NEMS) and Microelectromechanical Systems (MEMS) differ significantly in fabrication techniques, primarily due to their scale and material requirements. MEMS devices are commonly fabricated using photolithography, etching, and bulk or surface micromachining processes on silicon substrates, allowing precise control at the micrometer scale. NEMS fabrication pushes the limits further with techniques like electron beam lithography, focused ion beam milling, and atomic layer deposition to achieve nanometer-scale features, enhancing device sensitivity and performance for your advanced applications.

Core Materials Used

Core materials in Nanoelectromechanical Systems (NEMS) typically include silicon, graphene, carbon nanotubes, and other 2D materials, enabling enhanced mechanical strength and electrical properties at the nanoscale. In contrast, Microelectromechanical Systems (MEMS) primarily utilize silicon, polysilicon, silicon dioxide, and silicon nitride due to their established fabrication processes and mechanical stability at the microscale. The shift from MEMS to NEMS involves integrating novel nanomaterials to achieve improved sensitivity, reduced power consumption, and miniaturization in device performance.

Performance and Sensitivity

Nanoelectromechanical Systems (NEMS) demonstrate superior performance and sensitivity compared to Microelectromechanical Systems (MEMS) due to their significantly smaller dimensions, which enhance their resonant frequencies and reduce mass, enabling detection of minute forces and masses at the nanoscale. NEMS devices exhibit higher quality factors and faster response times, making them ideal for ultra-sensitive sensing applications such as single-molecule detection and quantum measurements. MEMS, while less sensitive, offer robust performance suitable for broader applications where larger mechanical structures and moderate sensitivity are sufficient.

Applications of NEMS

Nanoelectromechanical Systems (NEMS) are predominantly applied in ultra-sensitive sensors, including mass spectrometry and biological detection, where their nanoscale dimensions enable unprecedented sensitivity and precision. They play a critical role in quantum computing components and nano-scale signal processing, leveraging their enhanced mechanical and electrical properties. NEMS technology also advances energy harvesting and resonator applications, benefiting from their high resonance frequencies and low power consumption compared to MEMS.

Applications of MEMS

MEMS technology is widely applied in automotive systems for airbag sensors, tire pressure monitoring, and stability control due to its precision and reliability. In healthcare, MEMS devices enable advanced diagnostics and drug delivery through microfluidic systems and implantable sensors. Consumer electronics benefit from MEMS in accelerometers and gyroscopes for smartphones, gaming devices, and wearable technology, enhancing user interaction and device functionality.

Challenges in Development and Integration

Nanoelectromechanical Systems (NEMS) face significant challenges in fabrication due to the extreme precision required at the nanoscale, which affects material properties and device reliability compared to Microelectromechanical Systems (MEMS). Integrating NEMS with existing electronic systems demands overcoming issues related to signal noise and thermal management that are less pronounced in MEMS technology. Your efforts in developing these systems must address scalability and cost concerns while ensuring consistent performance in complex applications.

Future Trends and Innovations

Future trends in Nanoelectromechanical Systems (NEMS) emphasize ultra-sensitive sensors and energy-efficient nanoactuators, enabling unprecedented precision in medical diagnostics and environmental monitoring. Microelectromechanical Systems (MEMS) continue to advance with integration of AI-driven controls and wireless communication, expanding applications in smart devices and autonomous systems. Your ability to leverage the unique nanoscale functionalities of NEMS alongside mature MEMS technologies will drive innovative solutions across healthcare, telecommunications, and IoT sectors.

Nanoelectromechanical System (NEMS) vs Microelectromechanical System (MEMS) Infographic

electrown.com

electrown.com