Flexible nanoelectronics offer enhanced adaptability and durability in wearable and foldable devices, contrasting with the robustness and stability of rigid nanoelectronics used in traditional applications. Explore the rest of this article to understand how these technologies impact your choices in cutting-edge electronic devices.

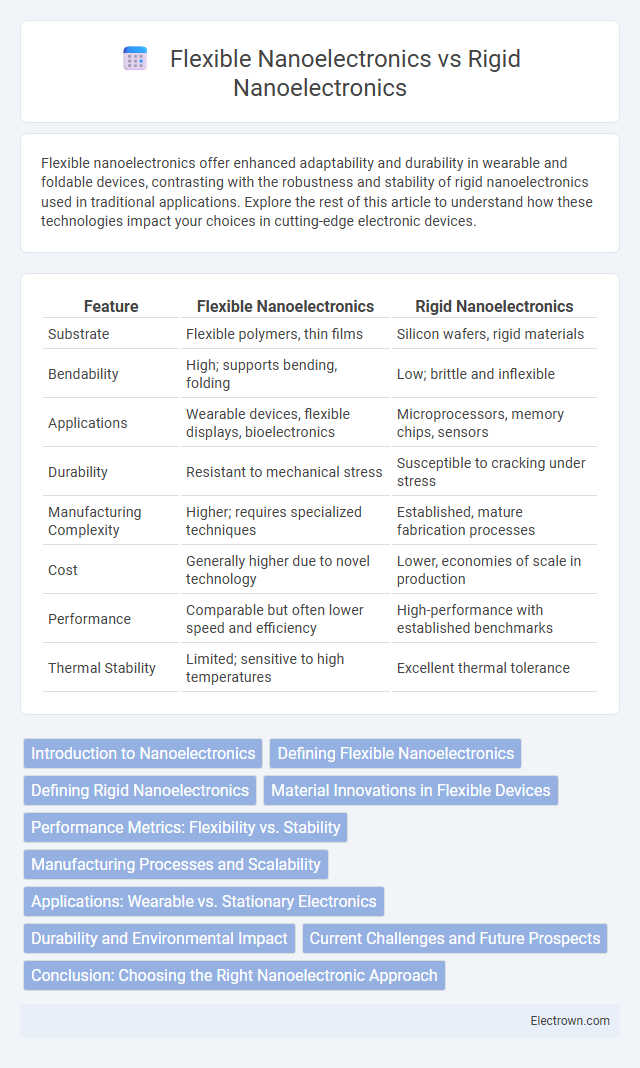

Table of Comparison

| Feature | Flexible Nanoelectronics | Rigid Nanoelectronics |

|---|---|---|

| Substrate | Flexible polymers, thin films | Silicon wafers, rigid materials |

| Bendability | High; supports bending, folding | Low; brittle and inflexible |

| Applications | Wearable devices, flexible displays, bioelectronics | Microprocessors, memory chips, sensors |

| Durability | Resistant to mechanical stress | Susceptible to cracking under stress |

| Manufacturing Complexity | Higher; requires specialized techniques | Established, mature fabrication processes |

| Cost | Generally higher due to novel technology | Lower, economies of scale in production |

| Performance | Comparable but often lower speed and efficiency | High-performance with established benchmarks |

| Thermal Stability | Limited; sensitive to high temperatures | Excellent thermal tolerance |

Introduction to Nanoelectronics

Nanoelectronics involves the use of nanometer-scale materials and devices to create electronic components with enhanced performance and reduced size. Flexible nanoelectronics utilize bendable, stretchable substrates like polymers to enable applications in wearable technology and foldable displays, while rigid nanoelectronics rely on traditional silicon-based substrates for high stability and performance in conventional electronics. The choice between flexible and rigid nanoelectronics depends on the specific requirements of device flexibility, durability, and application environment.

Defining Flexible Nanoelectronics

Flexible nanoelectronics refers to electronic devices built on bendable, stretchable substrates that maintain performance under mechanical deformation, contrasting with rigid nanoelectronics that rely on stiff, inflexible materials. These flexible systems enable wearable technology, foldable displays, and bio-integrated sensors by conforming to complex surfaces and dynamic movements. Your ability to harness flexible nanoelectronics facilitates innovations in personalized, adaptable, and durable electronic applications.

Defining Rigid Nanoelectronics

Rigid nanoelectronics are characterized by solid, inflexible substrates made from materials such as silicon wafers, which provide high stability and performance in nano-scale electronic devices. These systems excel in applications requiring durability and precise electronic properties but lack adaptability to curved or dynamic surfaces. Your choice between flexible and rigid nanoelectronics depends on the need for mechanical flexibility versus structural robustness in advanced technological applications.

Material Innovations in Flexible Devices

Flexible nanoelectronics leverage advanced materials like graphene, molybdenum disulfide, and organic semiconductors to achieve bendable, stretchable, and lightweight properties, contrasting with the brittle silicon-based materials in rigid nanoelectronics. These innovations enable devices that conform to irregular surfaces and endure mechanical stress without performance degradation. Your next-generation wearable or implantable device benefits from enhanced durability and comfort through these cutting-edge material breakthroughs.

Performance Metrics: Flexibility vs. Stability

Flexible nanoelectronics exhibit superior mechanical bendability and stretchability, enhancing device adaptability for wearable and deformable applications while maintaining acceptable electrical conductivity. Rigid nanoelectronics provide higher stability, thermal resistance, and consistent electrical performance under fixed form factors, crucial for high-precision and long-term operation. Performance metrics such as electrical mobility, fatigue resistance, and thermal stability highlight the trade-offs, with flexibility favoring resilience to mechanical stress and rigidity emphasizing durability and operational consistency.

Manufacturing Processes and Scalability

Flexible nanoelectronics leverage printing and roll-to-roll manufacturing processes, enabling cost-effective, large-area production with high scalability for wearable and implantable devices. Rigid nanoelectronics rely on conventional photolithography and etching techniques optimized for high precision but face scalability constraints due to rigid substrates and complex fabrication steps. Your choice impacts manufacturing throughput and scalability potential, with flexible nanoelectronics offering more adaptable production for emerging applications.

Applications: Wearable vs. Stationary Electronics

Flexible nanoelectronics enable advanced wearable applications, including health monitoring devices and smart textiles, by conforming to the human body and providing comfort during movement. Rigid nanoelectronics dominate stationary electronics such as laptops and desktop computers, offering stability and high-performance processing in fixed environments. Your choice between flexible and rigid nanoelectronics depends largely on whether portability or durability in a stationary setup is prioritized.

Durability and Environmental Impact

Flexible nanoelectronics offer enhanced durability through their ability to bend and stretch without breaking, making them ideal for wearable devices and implantable sensors exposed to dynamic environments. Rigid nanoelectronics, while generally more stable under static conditions, are prone to cracking and failure under mechanical stress, limiting their lifespan in flexible applications. Your choice impacts environmental sustainability since flexible devices often use materials with lower energy consumption during production and generate less electronic waste due to improved resilience.

Current Challenges and Future Prospects

Flexible nanoelectronics face challenges including mechanical durability, integration with existing rigid systems, and maintaining high performance under bending or stretching. Rigid nanoelectronics offer superior stability and performance but lack adaptability for wearable or foldable applications. Future prospects include advances in novel materials like graphene and organic semiconductors to enhance flexibility, along with hybrid systems combining rigid and flexible components for optimized functionality.

Conclusion: Choosing the Right Nanoelectronic Approach

Flexible nanoelectronics enable lightweight, bendable devices suitable for wearable technology and implantable sensors, enhancing user comfort and expanding application fields. Rigid nanoelectronics provide superior performance and stability for high-speed computing and precision instrumentation, maintaining structural integrity under demanding conditions. Selecting the appropriate nanoelectronic approach depends on specific application requirements, balancing flexibility with performance and durability constraints.

Flexible Nanoelectronics vs Rigid Nanoelectronics Infographic

electrown.com

electrown.com