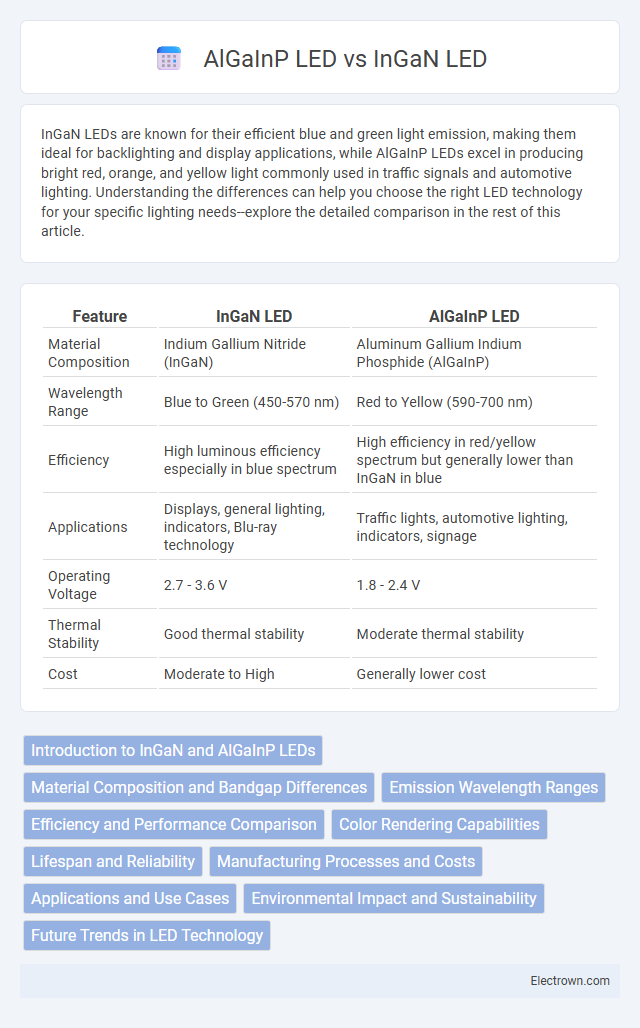

InGaN LEDs are known for their efficient blue and green light emission, making them ideal for backlighting and display applications, while AlGaInP LEDs excel in producing bright red, orange, and yellow light commonly used in traffic signals and automotive lighting. Understanding the differences can help you choose the right LED technology for your specific lighting needs--explore the detailed comparison in the rest of this article.

Table of Comparison

| Feature | InGaN LED | AlGaInP LED |

|---|---|---|

| Material Composition | Indium Gallium Nitride (InGaN) | Aluminum Gallium Indium Phosphide (AlGaInP) |

| Wavelength Range | Blue to Green (450-570 nm) | Red to Yellow (590-700 nm) |

| Efficiency | High luminous efficiency especially in blue spectrum | High efficiency in red/yellow spectrum but generally lower than InGaN in blue |

| Applications | Displays, general lighting, indicators, Blu-ray technology | Traffic lights, automotive lighting, indicators, signage |

| Operating Voltage | 2.7 - 3.6 V | 1.8 - 2.4 V |

| Thermal Stability | Good thermal stability | Moderate thermal stability |

| Cost | Moderate to High | Generally lower cost |

Introduction to InGaN and AlGaInP LEDs

InGaN LEDs, composed of Indium Gallium Nitride, excel in blue and green light emission with high efficiency and durability, crucial for displays and solid-state lighting. AlGaInP LEDs, made from Aluminum Gallium Indium Phosphide, primarily emit red, orange, and yellow light, offering superior luminous intensity ideal for indicators and automotive lighting. Your choice between InGaN and AlGaInP LEDs depends on the desired wavelength and application requirements, optimizing performance and energy consumption.

Material Composition and Bandgap Differences

InGaN LEDs are composed of Indium Gallium Nitride and exhibit a wide bandgap range typically from 2.0 to 3.4 eV, enabling efficient emission of blue to green light. AlGaInP LEDs, made from Aluminum Gallium Indium Phosphide, possess a narrower bandgap around 1.7 to 2.2 eV, suitable for producing red to yellow light. Your choice between these materials influences the LED's wavelength, efficiency, and application in color-specific lighting solutions.

Emission Wavelength Ranges

InGaN LEDs typically emit light within the blue to green wavelength range, approximately 450 to 530 nanometers, making them ideal for high-brightness applications and full-color displays. In contrast, AlGaInP LEDs cover the red to yellow spectral range, roughly 590 to 700 nanometers, which is advantageous for indicators and automotive lighting. The distinct emission wavelength ranges of InGaN and AlGaInP LEDs enable their specialized use in diverse optoelectronic applications requiring different colors and efficiencies.

Efficiency and Performance Comparison

InGaN LEDs generally offer higher luminous efficiency and better performance in the blue to green wavelength range, making them ideal for applications requiring bright, cool-colored light. AlGaInP LEDs excel in the red to yellow spectrum, delivering superior efficiency and brightness for warm-colored lighting. Your choice depends on the desired color output and application, with InGaN preferred for high-brightness displays and AlGaInP favored in indicator and automotive lighting.

Color Rendering Capabilities

InGaN LEDs offer superior color rendering capabilities primarily in blue and green wavelength ranges, enabling more vivid and accurate color reproduction for applications like displays and indoor lighting. AlGaInP LEDs excel in red to yellow wavelength emissions but typically have narrower spectral emissions, which can limit their ability to render colors as naturally as InGaN LEDs. Your choice depends on the desired application, with InGaN providing broader spectrum options for enhanced color quality.

Lifespan and Reliability

InGaN LEDs exhibit a longer lifespan and higher reliability compared to AlGaInP LEDs due to their superior thermal stability and lower susceptibility to degradation under high-current operation. InGaN materials maintain consistent performance over tens of thousands of hours, often exceeding 50,000 hours in typical applications. In contrast, AlGaInP LEDs generally have shorter operational lifespans, ranging from 20,000 to 30,000 hours, with increased vulnerability to efficiency droop and color shift over time.

Manufacturing Processes and Costs

InGaN LEDs are manufactured using metal-organic chemical vapor deposition (MOCVD) on sapphire or silicon carbide substrates, resulting in higher costs due to complex epitaxial growth and substrate expenses. AlGaInP LEDs, typically grown on gallium arsenide wafers with MOCVD, benefit from lower substrate costs and simpler fabrication steps, reducing overall production expenses. The cost difference is significant, with InGaN LEDs being more expensive to produce but offering superior performance in blue and green wavelengths, while AlGaInP LEDs are more cost-effective for red and yellow applications.

Applications and Use Cases

InGaN LEDs are widely used in blue and green lighting applications, including displays, automotive headlights, and general illumination due to their high efficiency and color stability. AlGaInP LEDs excel in red, orange, and yellow light applications such as traffic signals, indicator lights, and digital billboards because of their superior brightness and color purity in the visible spectrum. Both semiconductor materials are integral to specialized lighting systems, where InGaN suits high-brightness and full-color displays, while AlGaInP is preferred for energy-efficient, vibrant red and amber light sources.

Environmental Impact and Sustainability

InGaN LEDs exhibit greater environmental sustainability due to their higher energy efficiency and longer lifespan, reducing overall electricity consumption and waste. AlGaInP LEDs, while effective in red and amber light emission, generally consume more power and have shorter operational durations, leading to increased environmental footprint. The reduced use of rare earth elements in InGaN LEDs also contributes to their lower ecological impact compared to AlGaInP counterparts.

Future Trends in LED Technology

Future trends in LED technology emphasize improving efficiency and color range, with InGaN LEDs leading advancements in high-brightness blue and green light applications due to their superior electron mobility and thermal stability. AlGaInP LEDs remain dominant in red and amber wavelengths but face challenges in efficiency droop and heat dissipation, prompting research into novel materials and hybrid structures. Integration of InGaN with next-generation phosphors and innovative epitaxial growth techniques is expected to drive breakthroughs in dynamic lighting, micro-LED displays, and energy-efficient solid-state lighting solutions.

InGaN LED vs AlGaInP LED Infographic

electrown.com

electrown.com