Hybrid photonic integration combines different material systems and components to optimize performance and functionality, offering flexibility and scalability in device design. Understanding the differences between hybrid and monolithic integration can help you choose the best approach for your specific optical applications; read on to explore their advantages and limitations in detail.

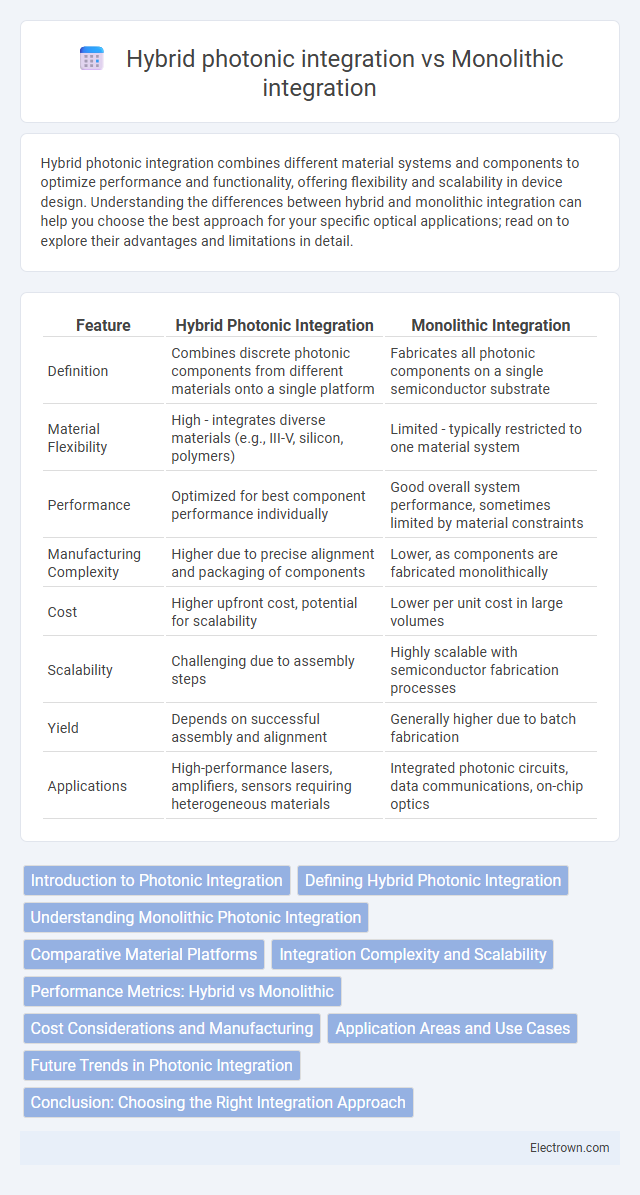

Table of Comparison

| Feature | Hybrid Photonic Integration | Monolithic Integration |

|---|---|---|

| Definition | Combines discrete photonic components from different materials onto a single platform | Fabricates all photonic components on a single semiconductor substrate |

| Material Flexibility | High - integrates diverse materials (e.g., III-V, silicon, polymers) | Limited - typically restricted to one material system |

| Performance | Optimized for best component performance individually | Good overall system performance, sometimes limited by material constraints |

| Manufacturing Complexity | Higher due to precise alignment and packaging of components | Lower, as components are fabricated monolithically |

| Cost | Higher upfront cost, potential for scalability | Lower per unit cost in large volumes |

| Scalability | Challenging due to assembly steps | Highly scalable with semiconductor fabrication processes |

| Yield | Depends on successful assembly and alignment | Generally higher due to batch fabrication |

| Applications | High-performance lasers, amplifiers, sensors requiring heterogeneous materials | Integrated photonic circuits, data communications, on-chip optics |

Introduction to Photonic Integration

Photonic integration involves combining multiple photonic functions into a single chip to improve performance and reduce size and cost. Hybrid photonic integration merges different material platforms and components, leveraging the strengths of each to optimize optical performance, whereas monolithic integration fabricates all components on a single substrate for seamless interaction and scalability. Hybrid approaches excel in material flexibility and heterogeneous integration, while monolithic offers better compactness and uniformity in manufacturing.

Defining Hybrid Photonic Integration

Hybrid photonic integration combines multiple photonic components fabricated on different substrates into a single functional module, enhancing performance and flexibility. Unlike monolithic integration, which involves fabricating all components on a single chip, hybrid integration allows for optimal material selection tailored to each component's function. This method enables superior scalability and customization in photonic circuits for applications such as telecommunications, sensing, and data processing.

Understanding Monolithic Photonic Integration

Monolithic photonic integration involves fabricating all optical components on a single substrate using a unified material system, enabling precise control over device performance and scalability. This approach enhances signal integrity, reduces interface losses, and improves system compactness compared to hybrid photonic integration, which combines different materials or separately fabricated components. Monolithic integration is crucial for applications requiring high-density photonic circuits with consistent, low-loss optical pathways.

Comparative Material Platforms

Hybrid photonic integration employs diverse material platforms such as silicon, III-V semiconductors, and lithium niobate to optimize specific device functions while monolithic integration relies on a single material system, often silicon photonics, for compactness and scalability. Hybrid platforms enable combining high-performance active and passive components, overcoming material limitations inherent in monolithic designs but face challenges in alignment and packaging complexity. Your choice between these integration methods depends on balancing device functionality, manufacturing complexity, and system performance requirements.

Integration Complexity and Scalability

Hybrid photonic integration offers reduced integration complexity by combining different material platforms optimized for specific functions, enabling easier assembly and testing compared to the all-in-one approach of monolithic integration. Scalability in hybrid integration benefits from modular design, allowing separate fabrication and mass production of components, whereas monolithic integration demands complex fabrication processes that escalate with device size and functionality. Your choice between these methods should weigh the trade-offs between ease of assembly and long-term scalability for advanced photonic systems.

Performance Metrics: Hybrid vs Monolithic

Hybrid photonic integration achieves superior performance by combining the best materials for each component, resulting in optimized optical gain, reduced insertion loss, and enhanced thermal management. Monolithic integration offers lower parasitic capacitance and improved scalability, delivering higher bandwidth and reliability through uniform material systems. Hybrid integration excels in versatile component performance, while monolithic integration provides consistent signal integrity and manufacturing efficiency.

Cost Considerations and Manufacturing

Hybrid photonic integration often lowers initial manufacturing costs by combining separately optimized components, enabling flexibility and faster prototyping with standard fabrication processes. Monolithic integration, while requiring costly and complex fabrication facilities, benefits from economies of scale and reduced packaging expenses in high-volume production. Cost considerations for hybrid integration include alignment and coupling challenges, whereas monolithic approaches face higher design and process development investments.

Application Areas and Use Cases

Hybrid photonic integration excels in diverse application areas such as telecommunications, data centers, and sensing systems due to its ability to combine different material platforms for optimized performance and cost-efficiency. Monolithic integration finds strong use cases in high-volume manufacturing for consumer electronics and optical transceivers, offering compactness and reduced assembly complexity by integrating all photonic components on a single chip. Both approaches serve critical roles in next-generation optical networks, with hybrid solutions targeting customizable, high-performance systems and monolithic designs enabling scalable, low-cost production.

Future Trends in Photonic Integration

Future trends in photonic integration emphasize hybrid integration due to its flexibility in combining diverse materials like silicon, indium phosphide, and lithium niobate, enabling high-performance, cost-effective photonic circuits. Emerging applications in data centers, telecommunications, and quantum computing drive research towards scalable hybrid platforms that optimize component performance and manufacturing yield. Monolithic integration, while providing compactness and reduced parasitics, faces material and fabrication challenges that limit its adaptability for complex, multifunctional photonic systems.

Conclusion: Choosing the Right Integration Approach

Hybrid photonic integration offers flexibility by combining disparate materials and components, enabling optimized performance across various wavelengths and applications. Monolithic integration provides superior scalability and reduced manufacturing complexity by fabricating all components on a single substrate, enhancing reliability and cost-effectiveness for high-volume production. Selecting between these approaches depends on specific requirements for performance, scalability, cost, and application complexity in photonic system design.

Hybrid photonic integration vs Monolithic integration Infographic

electrown.com

electrown.com