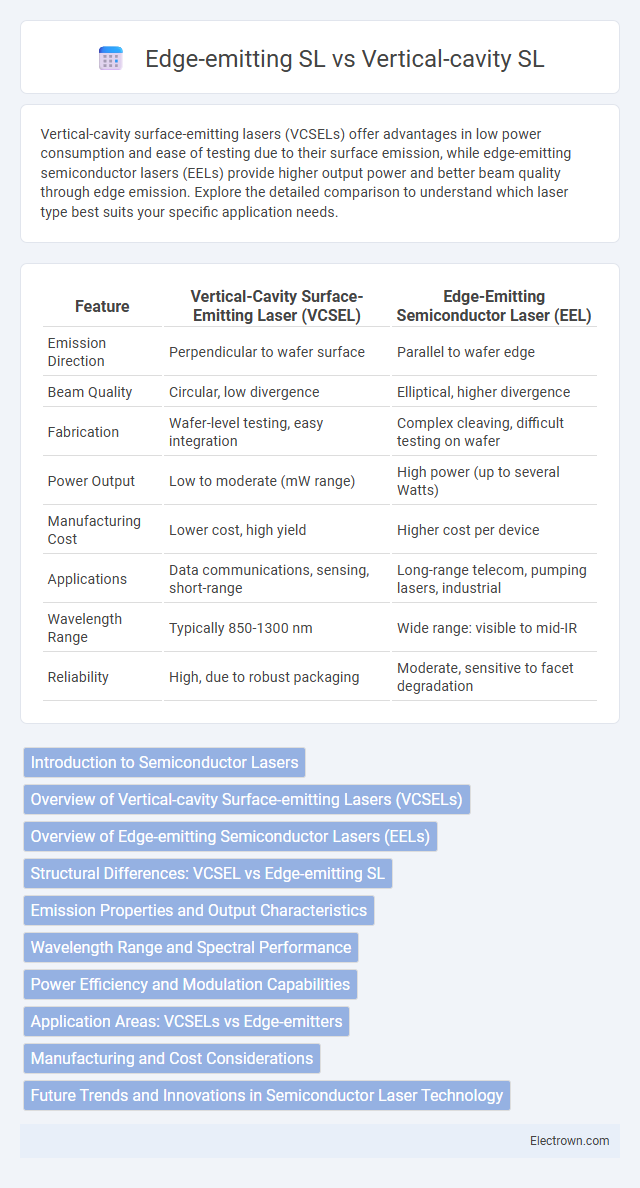

Vertical-cavity surface-emitting lasers (VCSELs) offer advantages in low power consumption and ease of testing due to their surface emission, while edge-emitting semiconductor lasers (EELs) provide higher output power and better beam quality through edge emission. Explore the detailed comparison to understand which laser type best suits your specific application needs.

Table of Comparison

| Feature | Vertical-Cavity Surface-Emitting Laser (VCSEL) | Edge-Emitting Semiconductor Laser (EEL) |

|---|---|---|

| Emission Direction | Perpendicular to wafer surface | Parallel to wafer edge |

| Beam Quality | Circular, low divergence | Elliptical, higher divergence |

| Fabrication | Wafer-level testing, easy integration | Complex cleaving, difficult testing on wafer |

| Power Output | Low to moderate (mW range) | High power (up to several Watts) |

| Manufacturing Cost | Lower cost, high yield | Higher cost per device |

| Applications | Data communications, sensing, short-range | Long-range telecom, pumping lasers, industrial |

| Wavelength Range | Typically 850-1300 nm | Wide range: visible to mid-IR |

| Reliability | High, due to robust packaging | Moderate, sensitive to facet degradation |

Introduction to Semiconductor Lasers

Semiconductor lasers are critical components in optical communication, with Vertical-cavity Surface-Emitting Lasers (VCSELs) and Edge-emitting Lasers (EELs) being two primary types. VCSELs emit light perpendicular to the wafer surface, offering low threshold current, circular beam profiles, and easier on-wafer testing, making them ideal for short-range data transmission. EELs emit light from the wafer edge, providing higher output power and narrow spectral linewidth, which suits long-distance communication and high-speed data applications.

Overview of Vertical-cavity Surface-emitting Lasers (VCSELs)

Vertical-cavity surface-emitting lasers (VCSELs) emit light perpendicular to the wafer surface, enabling high-density two-dimensional arrays and efficient coupling with optical fibers. Compared to edge-emitting lasers (EELs), VCSELs offer lower threshold currents, better beam quality, and simpler testing on-wafer due to their surface emission. Your choice of laser technology impacts device integration and performance in applications such as data communication, sensing, and 3D imaging.

Overview of Edge-emitting Semiconductor Lasers (EELs)

Edge-emitting semiconductor lasers (EELs) generate laser light by confining carriers and photons within a planar waveguide along the chip's edge, producing high-power, high-efficiency emission suitable for long-distance fiber optic communication and industrial applications. These lasers typically feature a stripe geometry that allows a larger active region compared to vertical-cavity surface-emitting lasers (VCSELs), resulting in greater output power and higher gain bandwidth. Your choice between EELs and VCSELs depends on application requirements such as beam quality, power scaling, and integration with optical fibers.

Structural Differences: VCSEL vs Edge-emitting SL

Vertical-cavity surface-emitting lasers (VCSELs) feature a short cavity with mirrors formed by distributed Bragg reflectors, enabling vertical emission of light perpendicular to the wafer surface. Edge-emitting semiconductor lasers (SL) possess a longer cavity with cleaved facets acting as mirrors, resulting in light emission parallel to the wafer surface. The structural design of VCSELs facilitates easier testing and integration into arrays, while edge-emitting SLs typically offer higher output power due to their extended cavity length.

Emission Properties and Output Characteristics

Vertical-cavity surface-emitting lasers (VCSELs) emit light perpendicular to the surface of the semiconductor chip, offering a circular beam shape and low divergence ideal for fiber coupling and short-distance communication. Edge-emitting semiconductor lasers produce light from the chip's edge, yielding higher output power and narrow spectral linewidth suitable for long-distance transmission and high-speed data links. Your choice depends on the application, balancing VCSEL's efficient, low-power emission with edge-emitting lasers' superior output intensity and beam quality.

Wavelength Range and Spectral Performance

Vertical-cavity surface-emitting lasers (VCSELs) typically operate in the wavelength range of 850 nm to 1300 nm, offering narrow spectral linewidths and high coherence ideal for precise sensing and high-speed data communication. Edge-emitting semiconductor lasers (EELs) cover a broader wavelength spectrum from 630 nm to 2000 nm, with moderate spectral linewidths suitable for applications requiring higher power output and broader tunability. The superior spectral purity and circular beam profile of VCSELs contrast with the higher output power and wavelength versatility of EELs, influencing their respective roles in telecommunications and industrial uses.

Power Efficiency and Modulation Capabilities

Vertical-cavity surface-emitting lasers (VCSELs) typically offer higher power efficiency due to their shorter cavity length and lower threshold currents compared to edge-emitting semiconductor lasers (SLs). VCSELs excel in high-speed modulation capabilities, making them ideal for data communication applications requiring rapid signal changes. Your choice between VCSELs and edge-emitting SLs should consider these factors based on the power consumption and modulation speed demands of your system.

Application Areas: VCSELs vs Edge-emitters

Vertical-cavity surface-emitting lasers (VCSELs) excel in short-distance optical interconnects, data communication, and sensing applications due to their low power consumption, circular beams, and ease of on-wafer testing. Edge-emitting lasers (EELs) dominate high-power and long-distance fiber optic communication, industrial material processing, and laser printing, benefiting from higher output power and narrow spectral linewidth. VCSELs are preferred in consumer electronics and data centers, while edge-emitters are critical in telecom infrastructure and high-precision manufacturing.

Manufacturing and Cost Considerations

Vertical-cavity surface-emitting lasers (VCSELs) benefit from simpler manufacturing due to their wafer-level testing and surface-normal emission, allowing for high-yield, low-cost mass production suitable for consumer electronics. Edge-emitting semiconductor lasers (SLs) require more complex cleaving and facet coating processes, increasing manufacturing difficulty and cost, though they often deliver higher power suitable for industrial applications. Your choice depends on cost sensitivity and performance requirements, with VCSELs offering scalability and affordability, while edge-emitters provide robust high-power solutions.

Future Trends and Innovations in Semiconductor Laser Technology

Vertical-cavity surface-emitting lasers (VCSELs) are advancing rapidly with innovations in high-speed modulation and wavelength multiplexing, making them ideal for next-generation data communication and sensing applications. Edge-emitting semiconductor lasers (EELs) continue to enhance power output and efficiency, driving developments in industrial machining, LiDAR, and medical devices. Your choice between VCSELs and EELs will depend on future demands for integration density, beam quality, and adaptability in evolving photonics technologies.

Vertical-cavity SL vs Edge-emitting SL Infographic

electrown.com

electrown.com