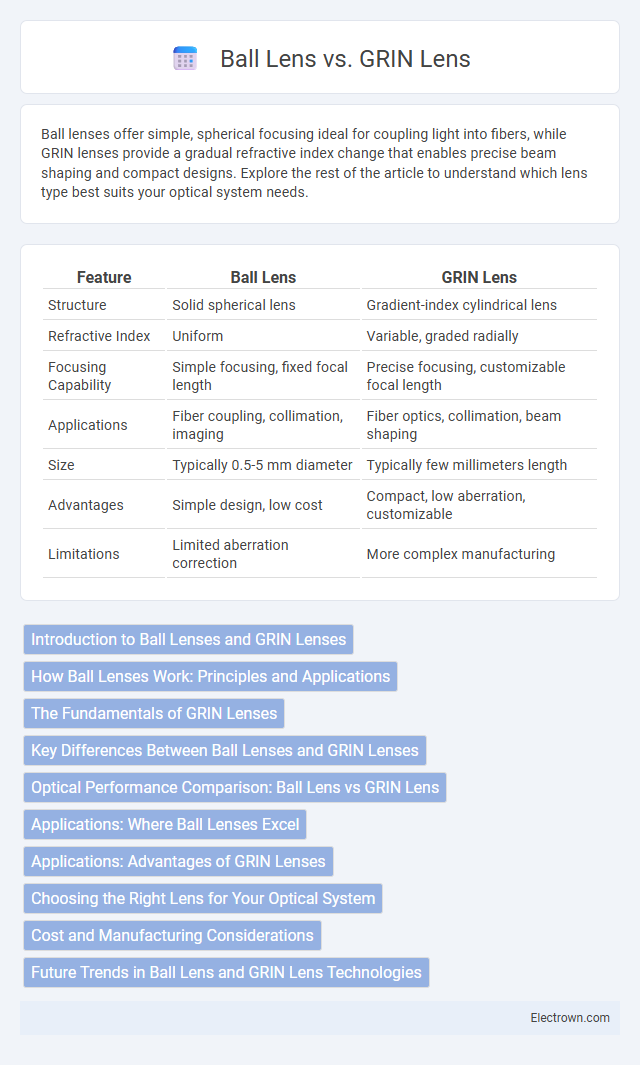

Ball lenses offer simple, spherical focusing ideal for coupling light into fibers, while GRIN lenses provide a gradual refractive index change that enables precise beam shaping and compact designs. Explore the rest of the article to understand which lens type best suits your optical system needs.

Table of Comparison

| Feature | Ball Lens | GRIN Lens |

|---|---|---|

| Structure | Solid spherical lens | Gradient-index cylindrical lens |

| Refractive Index | Uniform | Variable, graded radially |

| Focusing Capability | Simple focusing, fixed focal length | Precise focusing, customizable focal length |

| Applications | Fiber coupling, collimation, imaging | Fiber optics, collimation, beam shaping |

| Size | Typically 0.5-5 mm diameter | Typically few millimeters length |

| Advantages | Simple design, low cost | Compact, low aberration, customizable |

| Limitations | Limited aberration correction | More complex manufacturing |

Introduction to Ball Lenses and GRIN Lenses

Ball lenses are spherical optical components designed to focus or collimate light with minimal aberration, often used in fiber optic coupling and laser systems. GRIN lenses, or Gradient Index lenses, feature a refractive index that gradually changes radially, enabling precise light focusing and compact optical designs. Your choice between ball lenses and GRIN lenses depends on the specific application's requirements for size, focal precision, and light manipulation.

How Ball Lenses Work: Principles and Applications

Ball lenses focus light by using a spherical shape to refract and converge rays toward a focal point, minimizing spherical aberrations. Their compact design enables efficient coupling in fiber optics, laser collimation, and imaging systems. Common applications include beam focusing, optical pickup devices, and enhancing sensor performance due to their high numerical aperture and simple alignment.

The Fundamentals of GRIN Lenses

GRIN lenses use a gradient refractive index profile that continuously changes from the center to the edge, enabling precise light focusing and beam shaping within a compact form factor. Unlike ball lenses, which rely on a uniform refractive index and curved surfaces, GRIN lenses achieve their optical properties through internal material variations, allowing better control of focal length and reduced aberrations. Your optical system can benefit from GRIN lenses by obtaining higher-quality image resolution and more efficient light coupling in fiber optic applications.

Key Differences Between Ball Lenses and GRIN Lenses

Ball lenses are typically spherical and focus light by simply refracting it through their curved surfaces, whereas GRIN (Gradient Index) lenses possess a refractive index that gradually changes radially, enabling precise control over light propagation and focusing. Ball lenses are commonly used for coupling light into fibers or collimating beams, while GRIN lenses are favored in applications requiring compact, integrated optical systems due to their ability to focus and guide light within a short length. Your choice between ball lenses and GRIN lenses depends on factors like desired focal length, beam shaping needs, and system integration constraints.

Optical Performance Comparison: Ball Lens vs GRIN Lens

Ball lenses offer superior focusing capabilities with a high numerical aperture, making them ideal for coupling light into fibers and collimating laser beams. GRIN lenses provide a graded refractive index profile that enables precise beam shaping and minimal aberrations over longer distances. Your choice depends on the required focal length, with ball lenses excelling in short-focus applications and GRIN lenses preferred for complex optical systems demanding improved image quality.

Applications: Where Ball Lenses Excel

Ball lenses excel in applications requiring efficient light coupling, such as fiber optic communications, laser collimation, and imaging systems. Their symmetrical shape focuses light precisely with minimal spherical aberration, making them ideal for coupling laser diodes and multimode fibers. You can rely on ball lenses for compact, high-performance optical components in telecommunications and sensor technologies.

Applications: Advantages of GRIN Lenses

GRIN lenses offer superior beam shaping and coupling efficiency in fiber optics, making them ideal for telecommunications and biomedical imaging. Their compact size and precise refractive index gradient allow for better image resolution and reduced optical aberrations compared to traditional ball lenses. By choosing GRIN lenses, you optimize alignment flexibility and integration in miniaturized optical systems.

Choosing the Right Lens for Your Optical System

Ball lenses offer high numerical aperture and minimal spherical aberration, making them ideal for fiber coupling and collimation in compact optical systems. GRIN lenses provide continuous refractive index variation, enabling precise light focusing and imaging with reduced lens count and weight. Selecting the right lens depends on system requirements such as optical performance, size constraints, and application-specific factors like wavelength compatibility and alignment tolerance.

Cost and Manufacturing Considerations

Ball lenses offer lower manufacturing costs due to simpler spherical shaping and mass production techniques, making them ideal for budget-sensitive applications. GRIN lenses require complex gradient refractive index fabrication, increasing production expenses and limiting large-scale affordability. Cost efficiency in ball lenses comes from minimal post-processing, whereas GRIN lenses' intricate material doping demands advanced equipment and precision controls.

Future Trends in Ball Lens and GRIN Lens Technologies

Future trends in Ball lens and GRIN lens technologies emphasize miniaturization and integration with photonic circuits, enhancing optical performance in compact devices. Advances in materials science enable higher refractive indices and lower optical losses, expanding applications in telecommunications and biomedical imaging. Emerging manufacturing techniques such as 3D printing and nano-fabrication are driving cost reduction and precision improvements, accelerating adoption in consumer electronics and optical sensors.

Ball lens vs GRIN lens Infographic

electrown.com

electrown.com